Are you a seasoned Tool and Die Maker/Designer seeking a new career path? Discover our professionally built Tool and Die Maker/Designer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

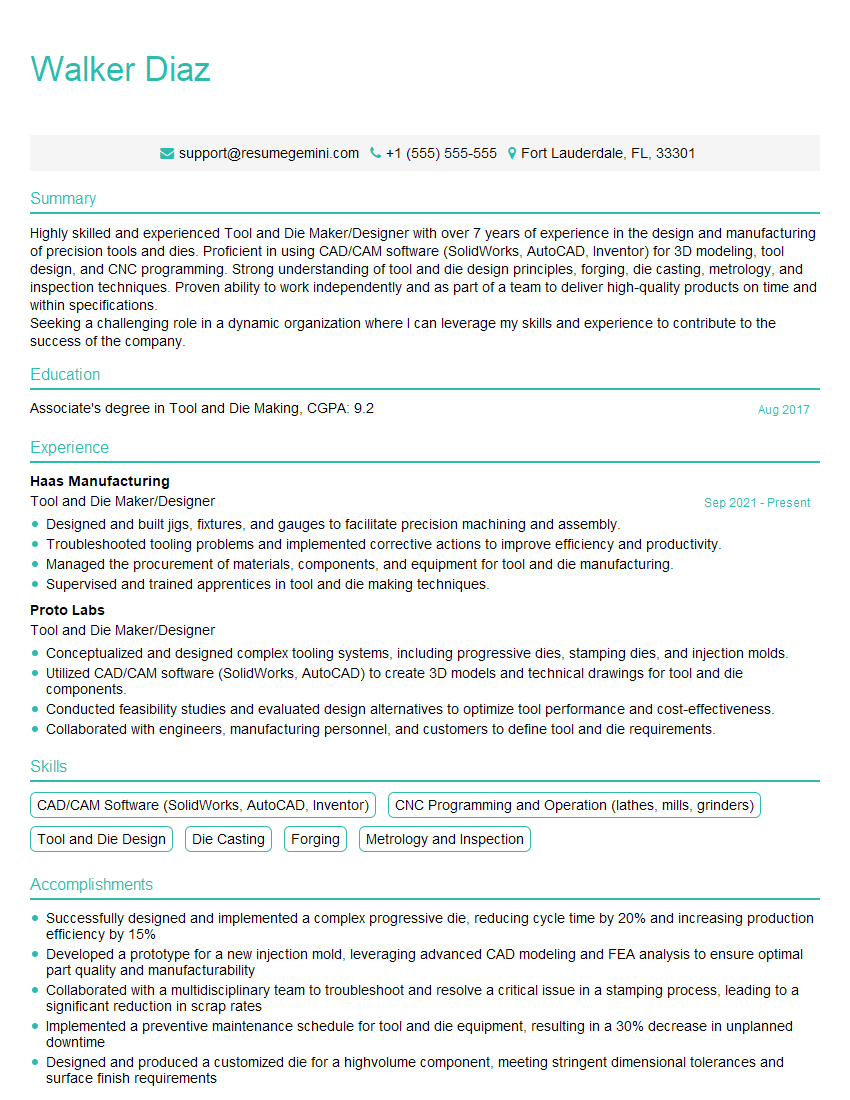

Walker Diaz

Tool and Die Maker/Designer

Summary

Highly skilled and experienced Tool and Die Maker/Designer with over 7 years of experience in the design and manufacturing of precision tools and dies. Proficient in using CAD/CAM software (SolidWorks, AutoCAD, Inventor) for 3D modeling, tool design, and CNC programming. Strong understanding of tool and die design principles, forging, die casting, metrology, and inspection techniques. Proven ability to work independently and as part of a team to deliver high-quality products on time and within specifications.

Seeking a challenging role in a dynamic organization where I can leverage my skills and experience to contribute to the success of the company.

Education

Associate’s degree in Tool and Die Making

August 2017

Skills

- CAD/CAM Software (SolidWorks, AutoCAD, Inventor)

- CNC Programming and Operation (lathes, mills, grinders)

- Tool and Die Design

- Die Casting

- Forging

- Metrology and Inspection

Work Experience

Tool and Die Maker/Designer

- Designed and built jigs, fixtures, and gauges to facilitate precision machining and assembly.

- Troubleshooted tooling problems and implemented corrective actions to improve efficiency and productivity.

- Managed the procurement of materials, components, and equipment for tool and die manufacturing.

- Supervised and trained apprentices in tool and die making techniques.

Tool and Die Maker/Designer

- Conceptualized and designed complex tooling systems, including progressive dies, stamping dies, and injection molds.

- Utilized CAD/CAM software (SolidWorks, AutoCAD) to create 3D models and technical drawings for tool and die components.

- Conducted feasibility studies and evaluated design alternatives to optimize tool performance and cost-effectiveness.

- Collaborated with engineers, manufacturing personnel, and customers to define tool and die requirements.

Accomplishments

- Successfully designed and implemented a complex progressive die, reducing cycle time by 20% and increasing production efficiency by 15%

- Developed a prototype for a new injection mold, leveraging advanced CAD modeling and FEA analysis to ensure optimal part quality and manufacturability

- Collaborated with a multidisciplinary team to troubleshoot and resolve a critical issue in a stamping process, leading to a significant reduction in scrap rates

- Implemented a preventive maintenance schedule for tool and die equipment, resulting in a 30% decrease in unplanned downtime

- Designed and produced a customized die for a highvolume component, meeting stringent dimensional tolerances and surface finish requirements

Awards

- Tool and Die Making Excellence Award, National Association of Tool and Die Makers (NATDM)

- Outstanding Die Design Award, Society of Manufacturing Engineers (SME)

- Best Apprentice Award, Tool and Die Craftsman Association

Certificates

- Certified Toolmaker (CTM)

- Certified Die Maker (CDM)

- ASME B107-2014 (Steel Die Design)

- ASME B108-2014 (Steel Rule Die Design)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool and Die Maker/Designer

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your skills and experience.

- Tailor your resume to each specific job you apply for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Tool and Die Maker/Designer Resume

- Design and develop tools and dies for various industries, including automotive, aerospace, and medical

- Use CAD/CAM software to create 3D models, generate CNC programs, and simulate tool paths

- Operate CNC machines (lathes, mills, grinders) to manufacture tools and dies to precise specifications

- Conduct metrology inspections to ensure that tools and dies meet dimensional requirements

- Troubleshoot and resolve manufacturing issues to minimize downtime and ensure product quality

- Collaborate with engineers, designers, and production staff to design and produce high-quality tools and dies

- Stay up-to-date with the latest technologies and industry best practices

Frequently Asked Questions (FAQ’s) For Tool and Die Maker/Designer

What is a Tool and Die Maker/Designer?

A Tool and Die Maker/Designer is a skilled professional who designs and manufactures tools and dies used in the production of various products, such as automotive parts, aerospace components, and medical devices.

What are the key skills required for a Tool and Die Maker/Designer?

Key skills for a Tool and Die Maker/Designer include proficiency in CAD/CAM software, CNC programming and operation, tool and die design, metrology and inspection, and forging and die casting.

What is the job outlook for Tool and Die Maker/Designers?

The job outlook for Tool and Die Maker/Designers is expected to be good in the coming years, as the demand for skilled professionals in this field continues to grow.

What is the average salary for a Tool and Die Maker/Designer?

The average salary for a Tool and Die Maker/Designer can vary depending on factors such as experience, location, and industry.

What are the career advancement opportunities for Tool and Die Maker/Designers?

Tool and Die Maker/Designers can advance their careers by taking on leadership roles, such as supervisor or manager. They can also specialize in a particular area of tool and die making, such as design or manufacturing.

What are the educational requirements for a Tool and Die Maker/Designer?

While some Tool and Die Maker/Designers learn their trade through apprenticeships, most employers prefer candidates with an associate’s degree in Tool and Die Making or a related field.

What are the certifications available for Tool and Die Maker/Designers?

There are several certifications available for Tool and Die Maker/Designers, such as the Certified Tool and Die Maker (CTDM) certification offered by the Society of Manufacturing Engineers (SME).