Are you a seasoned Tool and Die Supervisor seeking a new career path? Discover our professionally built Tool and Die Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

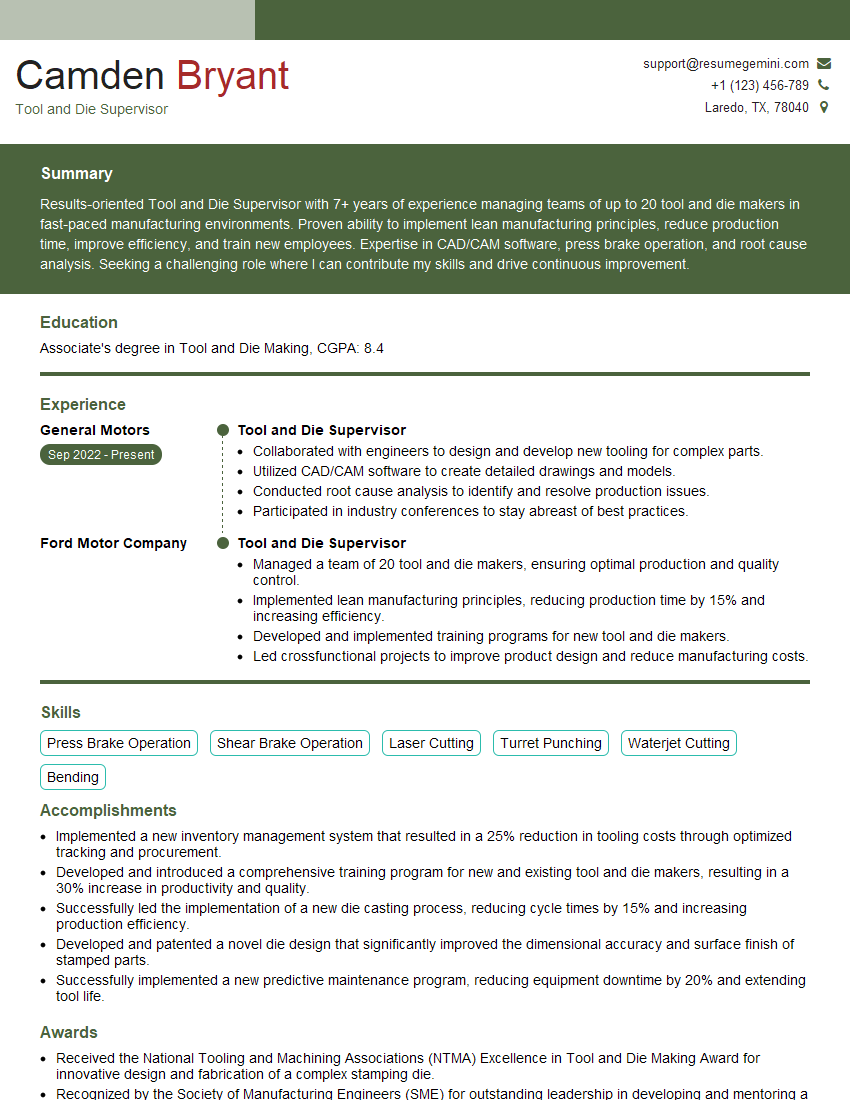

Camden Bryant

Tool and Die Supervisor

Summary

Results-oriented Tool and Die Supervisor with 7+ years of experience managing teams of up to 20 tool and die makers in fast-paced manufacturing environments. Proven ability to implement lean manufacturing principles, reduce production time, improve efficiency, and train new employees. Expertise in CAD/CAM software, press brake operation, and root cause analysis. Seeking a challenging role where I can contribute my skills and drive continuous improvement.

Education

Associate’s degree in Tool and Die Making

August 2018

Skills

- Press Brake Operation

- Shear Brake Operation

- Laser Cutting

- Turret Punching

- Waterjet Cutting

- Bending

Work Experience

Tool and Die Supervisor

- Collaborated with engineers to design and develop new tooling for complex parts.

- Utilized CAD/CAM software to create detailed drawings and models.

- Conducted root cause analysis to identify and resolve production issues.

- Participated in industry conferences to stay abreast of best practices.

Tool and Die Supervisor

- Managed a team of 20 tool and die makers, ensuring optimal production and quality control.

- Implemented lean manufacturing principles, reducing production time by 15% and increasing efficiency.

- Developed and implemented training programs for new tool and die makers.

- Led crossfunctional projects to improve product design and reduce manufacturing costs.

Accomplishments

- Implemented a new inventory management system that resulted in a 25% reduction in tooling costs through optimized tracking and procurement.

- Developed and introduced a comprehensive training program for new and existing tool and die makers, resulting in a 30% increase in productivity and quality.

- Successfully led the implementation of a new die casting process, reducing cycle times by 15% and increasing production efficiency.

- Developed and patented a novel die design that significantly improved the dimensional accuracy and surface finish of stamped parts.

- Successfully implemented a new predictive maintenance program, reducing equipment downtime by 20% and extending tool life.

Awards

- Received the National Tooling and Machining Associations (NTMA) Excellence in Tool and Die Making Award for innovative design and fabrication of a complex stamping die.

- Recognized by the Society of Manufacturing Engineers (SME) for outstanding leadership in developing and mentoring a team of apprentice toolmakers.

- Awarded the American Machinists Top 100 Metalworkers Award for exceptional contributions to the tool and die industry.

- Honored with the National Mold and Equipment Builders Association (NMEBA) Award for excellence in mold and die design and manufacturing.

Certificates

- Certified Tool and Die Maker (CTDM)

- ISO 9001:2015

- ASME B1.1

- GD&T Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool and Die Supervisor

- Highlight your experience and skills in lean manufacturing and continuous improvement.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your expertise in CAD/CAM software and other relevant technical tools.

- Emphasize your leadership and management abilities, including your experience in training and developing teams.

- Tailor your resume to each specific job application, highlighting the skills and experience that are most relevant to the role.

Essential Experience Highlights for a Strong Tool and Die Supervisor Resume

- Managed a team of 20+ tool and die makers, providing guidance, training, and support.

- Implemented lean manufacturing principles, reducing production time by 15% and increasing overall efficiency.

- Collaborated with engineers and designers to develop and implement new tooling solutions for complex parts.

- Utilized CAD/CAM software to create detailed drawings and 3D models.

- Conducted root cause analysis to identify and resolve production issues, minimizing downtime and waste.

- Participated in industry conferences and workshops to stay abreast of best practices and technological advancements.

- Coordinated with vendors to procure materials and equipment, ensuring timely delivery and cost optimization.

Frequently Asked Questions (FAQ’s) For Tool and Die Supervisor

What are the key responsibilities of a Tool and Die Supervisor?

Tool and Die Supervisors are responsible for overseeing the production of tools, dies, and other components used in manufacturing processes. They manage teams of tool and die makers, ensuring that production meets quality standards and deadlines. They also work closely with engineers and designers to develop new tooling solutions and implement continuous improvement initiatives.

What qualifications are typically required to become a Tool and Die Supervisor?

Most Tool and Die Supervisors have an associate’s degree or higher in a related field, such as tool and die making or manufacturing engineering. They also have several years of experience working in a manufacturing environment, with a strong understanding of tool and die making processes. Additionally, they typically have experience in lean manufacturing principles and CAD/CAM software.

What are the career prospects for Tool and Die Supervisors?

Tool and Die Supervisors are in high demand in the manufacturing industry. As the industry continues to grow and evolve, the need for skilled supervisors will only increase. With experience and additional training, Tool and Die Supervisors can advance to management positions, such as Production Manager or Plant Manager.

What are the challenges faced by Tool and Die Supervisors?

Tool and Die Supervisors face a number of challenges, including the need to keep up with the latest manufacturing technologies, manage a team of skilled workers, and meet production deadlines. They also need to be able to work independently and as part of a team, and be able to solve problems quickly and effectively.

What are some tips for writing a standout Tool and Die Supervisor resume?

When writing a resume for a Tool and Die Supervisor position, it is important to highlight your experience and skills in lean manufacturing, CAD/CAM software, and team management. You should also quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact. Additionally, you should tailor your resume to each specific job application, highlighting the skills and experience that are most relevant to the role.