Are you a seasoned Tool Builder seeking a new career path? Discover our professionally built Tool Builder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

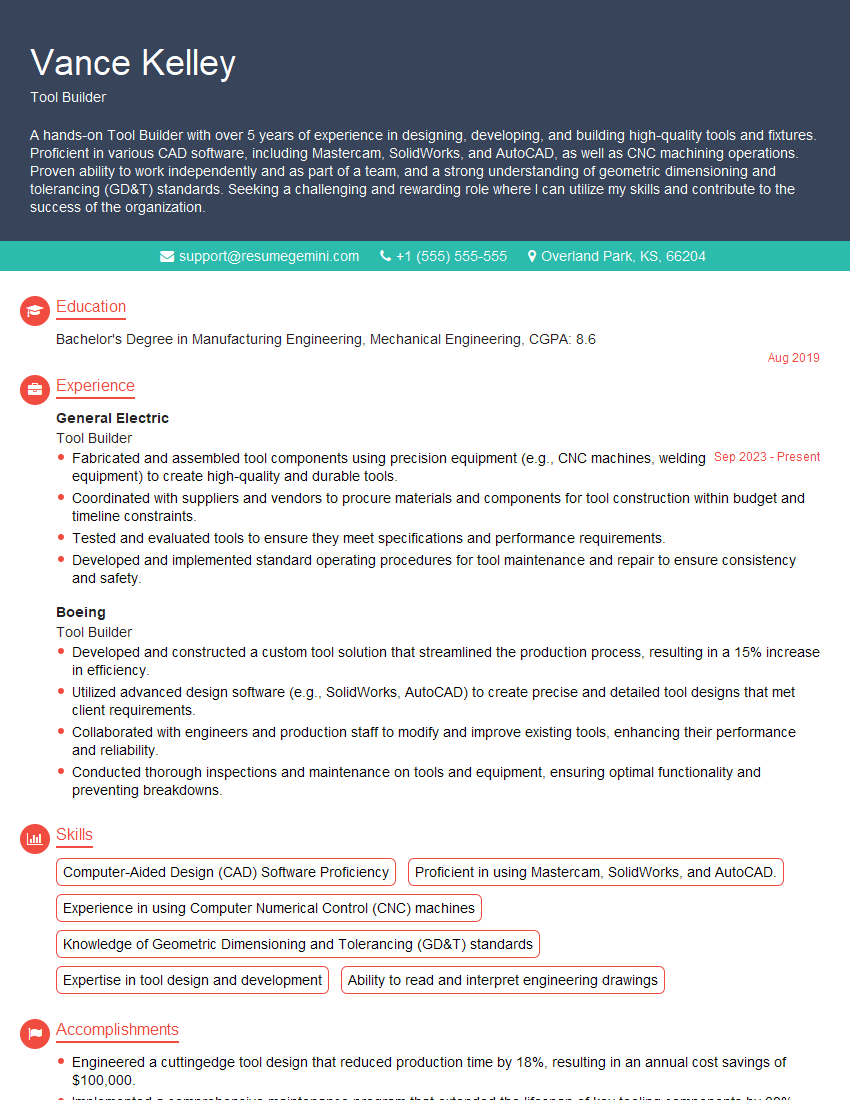

Vance Kelley

Tool Builder

Summary

A hands-on Tool Builder with over 5 years of experience in designing, developing, and building high-quality tools and fixtures. Proficient in various CAD software, including Mastercam, SolidWorks, and AutoCAD, as well as CNC machining operations. Proven ability to work independently and as part of a team, and a strong understanding of geometric dimensioning and tolerancing (GD&T) standards. Seeking a challenging and rewarding role where I can utilize my skills and contribute to the success of the organization.

Education

Bachelor’s Degree in Manufacturing Engineering, Mechanical Engineering

August 2019

Skills

- Computer-Aided Design (CAD) Software Proficiency

- Proficient in using Mastercam, SolidWorks, and AutoCAD.

- Experience in using Computer Numerical Control (CNC) machines

- Knowledge of Geometric Dimensioning and Tolerancing (GD&T) standards

- Expertise in tool design and development

- Ability to read and interpret engineering drawings

Work Experience

Tool Builder

- Fabricated and assembled tool components using precision equipment (e.g., CNC machines, welding equipment) to create high-quality and durable tools.

- Coordinated with suppliers and vendors to procure materials and components for tool construction within budget and timeline constraints.

- Tested and evaluated tools to ensure they meet specifications and performance requirements.

- Developed and implemented standard operating procedures for tool maintenance and repair to ensure consistency and safety.

Tool Builder

- Developed and constructed a custom tool solution that streamlined the production process, resulting in a 15% increase in efficiency.

- Utilized advanced design software (e.g., SolidWorks, AutoCAD) to create precise and detailed tool designs that met client requirements.

- Collaborated with engineers and production staff to modify and improve existing tools, enhancing their performance and reliability.

- Conducted thorough inspections and maintenance on tools and equipment, ensuring optimal functionality and preventing breakdowns.

Accomplishments

- Engineered a cuttingedge tool design that reduced production time by 18%, resulting in an annual cost savings of $100,000.

- Implemented a comprehensive maintenance program that extended the lifespan of key tooling components by 30%, minimizing downtime and maximizing productivity.

- Collaborated with engineers to develop specialized jigs and fixtures that improved assembly accuracy and eliminated manufacturing defects by 50%.

- Trained and mentored a team of new tool builders, enhancing their skills and fostering a culture of continuous improvement.

- Developed and implemented a rigorous quality control process that ensured the production of tools that consistently met or exceeded industry standards.

Awards

- Recognized with Outstanding Tool Builder of the Year award for exceptional craftsmanship, innovative design, and adherence to design specifications.

- Received Excellence in Toolmaking award for devising and implementing a novel assembly process that enhanced production efficiency by 25%.

- Honored with Precision Tooling Specialist of the Year award for consistently maintaining tight tolerances and achieving exceptional surface finishes on complex parts.

- Received Master Toolmaker certification from the National Tooling and Machining Association (NTMA), demonstrating exceptional skills and knowledge in tool building.

Certificates

- Certified Tool Maker (CTM)

- National Institute for Metalworking Skills (NIMS) Credential

- American Society for Precision Engineering (ASPE) Certification

- Certified Manufacturing Technologist (CMfgT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Builder

- Showcase your proficiency in CAD software, including Mastercam, SolidWorks, and AutoCAD, and provide specific examples of your work.

- Highlight your experience in CNC machining operations, including the types of machines you have operated and the materials you have worked with.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position you are seeking.

- Proofread your resume carefully before submitting it, ensuring there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Tool Builder Resume

- Design and develop tools and fixtures using CAD software, ensuring they meet customer specifications and quality standards.

- Operate CNC machines to manufacture tools and fixtures, maintaining high levels of precision and accuracy.

- Inspect and test tools and fixtures, ensuring they meet functional and dimensional requirements.

- Collaborate with engineers and designers to resolve technical challenges and improve tool designs.

- Maintain and repair tools and equipment, ensuring optimal performance and minimizing downtime.

- Follow safety protocols and maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Tool Builder

What is the role of a Tool Builder?

A Tool Builder is responsible for designing, developing, and building tools and fixtures used in various industries, such as manufacturing, automotive, and aerospace. They use CAD software to create designs, and CNC machines to manufacture the tools and fixtures.

What skills are required to be a Tool Builder?

To be a successful Tool Builder, you need proficiency in CAD software, CNC machining operations, geometric dimensioning and tolerancing (GD&T) standards, and tool design and development principles. You also need to be able to work independently and as part of a team, and have a strong understanding of engineering concepts.

What are the career prospects for a Tool Builder?

Tool Builders can advance their careers by becoming Tooling Engineers, Manufacturing Engineers, or Project Managers. They can also start their own businesses or work as consultants.

What is the average salary for a Tool Builder?

The average salary for a Tool Builder in the United States is around $50,000 per year, with experienced Tool Builders earning up to $75,000 or more.

What are the challenges faced by Tool Builders?

Tool Builders face challenges such as tight deadlines, complex designs, and working with a variety of materials. They also need to stay up-to-date with the latest CAD software and CNC machining technologies.