Are you a seasoned Tool/Die Maker seeking a new career path? Discover our professionally built Tool/Die Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

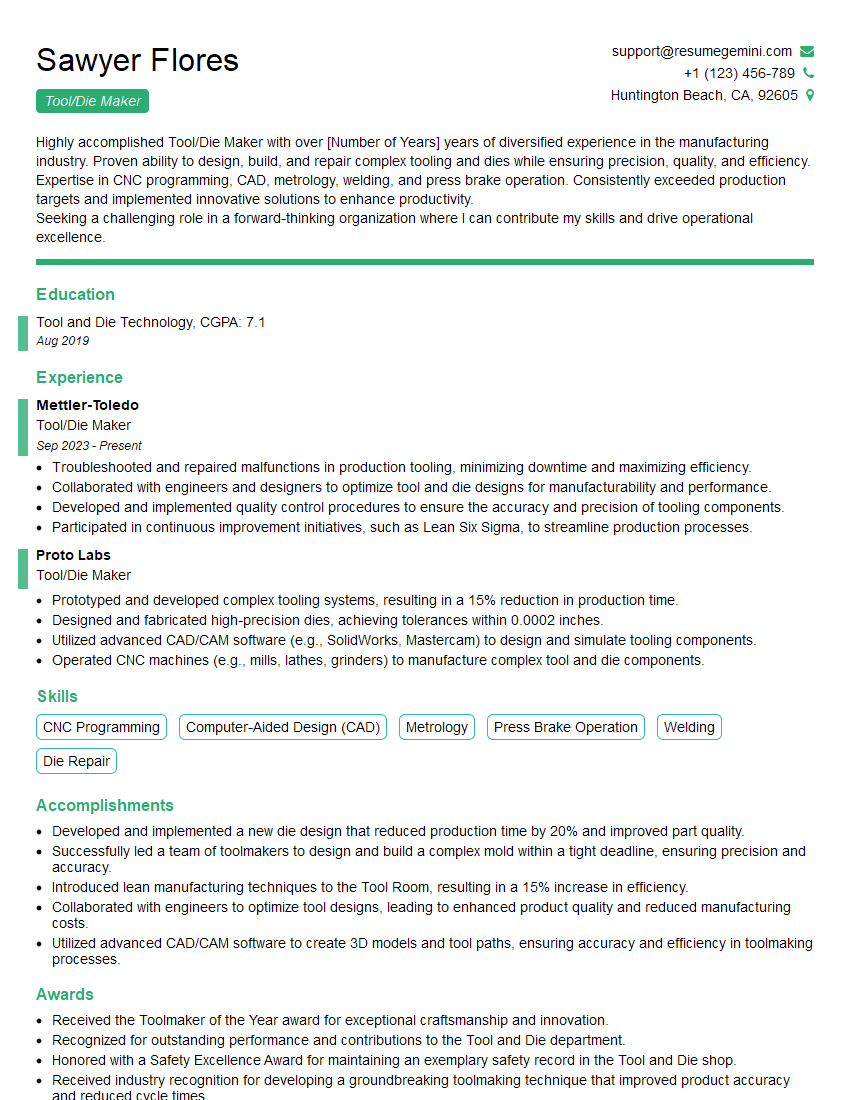

Sawyer Flores

Tool/Die Maker

Summary

Highly accomplished Tool/Die Maker with over [Number of Years] years of diversified experience in the manufacturing industry. Proven ability to design, build, and repair complex tooling and dies while ensuring precision, quality, and efficiency. Expertise in CNC programming, CAD, metrology, welding, and press brake operation. Consistently exceeded production targets and implemented innovative solutions to enhance productivity.

Seeking a challenging role in a forward-thinking organization where I can contribute my skills and drive operational excellence.

Education

Tool and Die Technology

August 2019

Skills

- CNC Programming

- Computer-Aided Design (CAD)

- Metrology

- Press Brake Operation

- Welding

- Die Repair

Work Experience

Tool/Die Maker

- Troubleshooted and repaired malfunctions in production tooling, minimizing downtime and maximizing efficiency.

- Collaborated with engineers and designers to optimize tool and die designs for manufacturability and performance.

- Developed and implemented quality control procedures to ensure the accuracy and precision of tooling components.

- Participated in continuous improvement initiatives, such as Lean Six Sigma, to streamline production processes.

Tool/Die Maker

- Prototyped and developed complex tooling systems, resulting in a 15% reduction in production time.

- Designed and fabricated high-precision dies, achieving tolerances within 0.0002 inches.

- Utilized advanced CAD/CAM software (e.g., SolidWorks, Mastercam) to design and simulate tooling components.

- Operated CNC machines (e.g., mills, lathes, grinders) to manufacture complex tool and die components.

Accomplishments

- Developed and implemented a new die design that reduced production time by 20% and improved part quality.

- Successfully led a team of toolmakers to design and build a complex mold within a tight deadline, ensuring precision and accuracy.

- Introduced lean manufacturing techniques to the Tool Room, resulting in a 15% increase in efficiency.

- Collaborated with engineers to optimize tool designs, leading to enhanced product quality and reduced manufacturing costs.

- Utilized advanced CAD/CAM software to create 3D models and tool paths, ensuring accuracy and efficiency in toolmaking processes.

Awards

- Received the Toolmaker of the Year award for exceptional craftsmanship and innovation.

- Recognized for outstanding performance and contributions to the Tool and Die department.

- Honored with a Safety Excellence Award for maintaining an exemplary safety record in the Tool and Die shop.

- Received industry recognition for developing a groundbreaking toolmaking technique that improved product accuracy and reduced cycle times.

Certificates

- Certified Toolmaker (CTM) from the Society of Manufacturing Engineers (SME)

- Certified Die Maker (CDM) from the American Die Casting Institute (ADCI)

- Certified Metalworking Technician (CMT) from the National Tooling and Machining Association (NTMA)

- Certified Moldmaker (CMM) from the American Mold Builders Association (AMBA)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool/Die Maker

- Highlight your technical expertise in CNC programming, CAD, and metrology.

- Showcase your experience in manufacturing complex tooling and dies, including their design, fabrication, and repair.

- Quantify your accomplishments whenever possible, using specific metrics and data.

- Demonstrate your commitment to quality, precision, and continuous improvement.

Essential Experience Highlights for a Strong Tool/Die Maker Resume

- Collaborated with engineers and production teams to develop and manufacture precision tooling and dies

- Programmed and operated CNC machines, including mills, lathes, and EDM, to create components within tight tolerances

- Utilized CAD software (e.g., SolidWorks, AutoCAD) to design and modify tooling and dies

- Performed preventive maintenance and repairs on tooling and dies, ensuring optimal performance and longevity

- Conducted quality inspections and implemented statistical process control techniques to maintain quality standards

- Followed safety protocols and maintained a clean and organized work environment

- Participated in continuous improvement initiatives to optimize processes and reduce downtime

Frequently Asked Questions (FAQ’s) For Tool/Die Maker

What is the role of a Tool/Die Maker?

A Tool/Die Maker is responsible for designing, building, and repairing tooling and dies used in the manufacturing industry. They work closely with engineers and production teams to develop and produce precision components and parts.

What skills are required for a Tool/Die Maker?

Tool/Die Makers typically have a strong foundation in CNC programming, CAD, metrology, welding, and press brake operation. They also possess excellent problem-solving and analytical skills, and a keen attention to detail.

What are the career prospects for a Tool/Die Maker?

Tool/Die Makers are in high demand in various industries, including automotive, aerospace, and medical. They can advance to supervisory or management roles, or specialize in specific areas such as design or repair.

What is the work environment of a Tool/Die Maker?

Tool/Die Makers typically work in manufacturing facilities, operating CNC machines and other equipment. They may work independently or as part of a team, and often collaborate with engineers, production personnel, and quality assurance staff.

What are the educational requirements for a Tool/Die Maker?

Most Tool/Die Makers have a high school diploma or equivalent, and complete an apprenticeship or vocational training program. Some may also pursue an associate’s degree in tool and die technology or a related field.

What are the key qualities of a successful Tool/Die Maker?

Successful Tool/Die Makers are detail-oriented, have strong problem-solving skills, and are committed to quality. They are also proficient in using CNC machines, CAD software, and other industry-specific tools and equipment.

What is the average salary of a Tool/Die Maker?

The average salary for a Tool/Die Maker varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Tool and Die Makers was $58,450 in May 2021.

Is the Tool/Die Maker profession in demand?

Yes, Tool/Die Makers are in high demand due to the growing need for precision manufacturing in various industries. The aging workforce and the need for skilled workers to operate and maintain advanced machinery further contribute to the demand for Tool/Die Makers.