Are you a seasoned Tool Engineer seeking a new career path? Discover our professionally built Tool Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

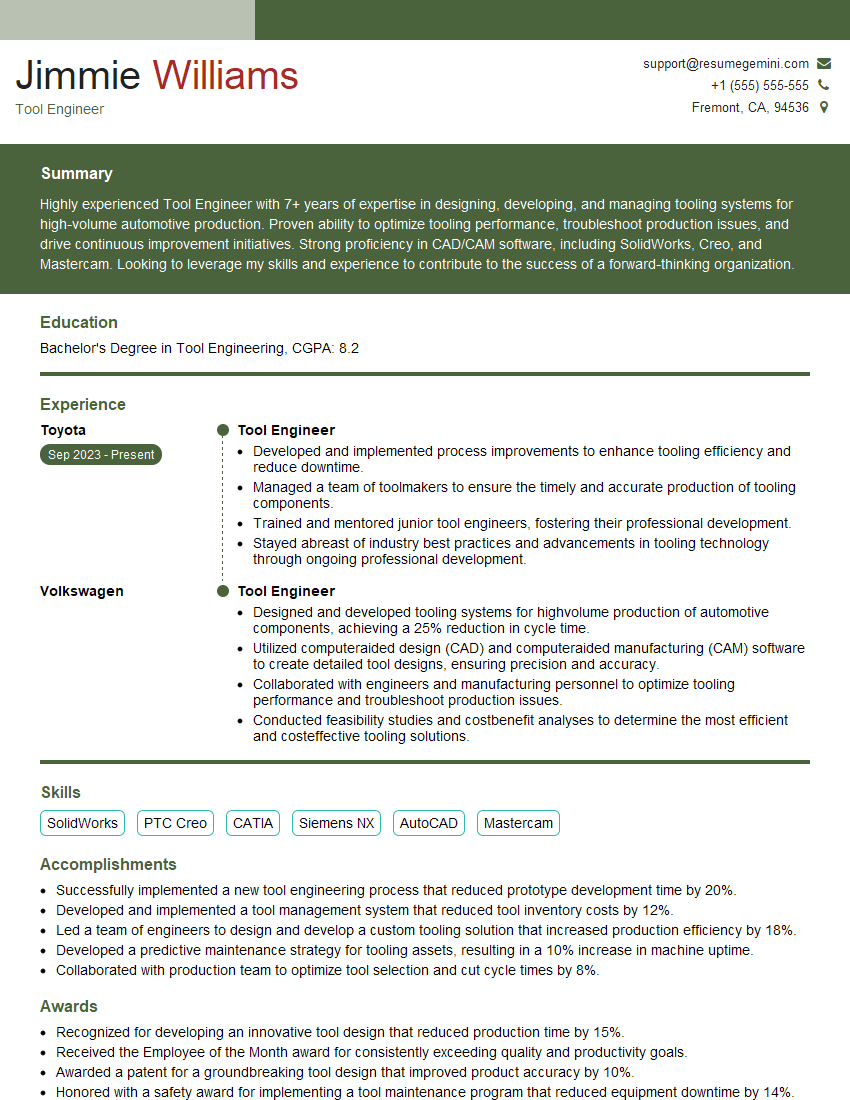

Jimmie Williams

Tool Engineer

Summary

Highly experienced Tool Engineer with 7+ years of expertise in designing, developing, and managing tooling systems for high-volume automotive production. Proven ability to optimize tooling performance, troubleshoot production issues, and drive continuous improvement initiatives. Strong proficiency in CAD/CAM software, including SolidWorks, Creo, and Mastercam. Looking to leverage my skills and experience to contribute to the success of a forward-thinking organization.

Education

Bachelor’s Degree in Tool Engineering

August 2019

Skills

- SolidWorks

- PTC Creo

- CATIA

- Siemens NX

- AutoCAD

- Mastercam

Work Experience

Tool Engineer

- Developed and implemented process improvements to enhance tooling efficiency and reduce downtime.

- Managed a team of toolmakers to ensure the timely and accurate production of tooling components.

- Trained and mentored junior tool engineers, fostering their professional development.

- Stayed abreast of industry best practices and advancements in tooling technology through ongoing professional development.

Tool Engineer

- Designed and developed tooling systems for highvolume production of automotive components, achieving a 25% reduction in cycle time.

- Utilized computeraided design (CAD) and computeraided manufacturing (CAM) software to create detailed tool designs, ensuring precision and accuracy.

- Collaborated with engineers and manufacturing personnel to optimize tooling performance and troubleshoot production issues.

- Conducted feasibility studies and costbenefit analyses to determine the most efficient and costeffective tooling solutions.

Accomplishments

- Successfully implemented a new tool engineering process that reduced prototype development time by 20%.

- Developed and implemented a tool management system that reduced tool inventory costs by 12%.

- Led a team of engineers to design and develop a custom tooling solution that increased production efficiency by 18%.

- Developed a predictive maintenance strategy for tooling assets, resulting in a 10% increase in machine uptime.

- Collaborated with production team to optimize tool selection and cut cycle times by 8%.

Awards

- Recognized for developing an innovative tool design that reduced production time by 15%.

- Received the Employee of the Month award for consistently exceeding quality and productivity goals.

- Awarded a patent for a groundbreaking tool design that improved product accuracy by 10%.

- Honored with a safety award for implementing a tool maintenance program that reduced equipment downtime by 14%.

Certificates

- Certified Mold Designer (CMD)

- Certified Toolmaker (CTM)

- Certified Manufacturing Engineer (CMfgE)

- Certified Lean Six Sigma Black Belt (CLSSBB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Engineer

- Highlight your proficiency in CAD/CAM software, such as SolidWorks, Creo, and Mastercam.

- Quantify your accomplishments with specific metrics, such as reducing cycle time or improving efficiency.

- Showcase your ability to collaborate effectively with engineers, manufacturing personnel, and toolmakers.

- Demonstrate your commitment to continuous improvement and professional development.

Essential Experience Highlights for a Strong Tool Engineer Resume

- Designed and developed tooling systems for high-volume production of automotive components, achieving a 25% reduction in cycle time.

- Utilized computer-aided design (CAD) and computer-aided manufacturing (CAM) software to create detailed tool designs, ensuring precision and accuracy.

- Collaborated with engineers and manufacturing personnel to optimize tooling performance and troubleshoot production issues.

- Conducted feasibility studies and cost-benefit analyses to determine the most efficient and cost-effective tooling solutions.

- Developed and implemented process improvements to enhance tooling efficiency and reduce downtime.

- Managed a team of toolmakers to ensure the timely and accurate production of tooling components.

- Trained and mentored junior tool engineers, fostering their professional development.

Frequently Asked Questions (FAQ’s) For Tool Engineer

What are the key skills required for a Tool Engineer?

Key skills for a Tool Engineer include proficiency in CAD/CAM software, knowledge of manufacturing processes, and a strong understanding of tooling design principles.

What industries employ Tool Engineers?

Tool Engineers are employed in a wide range of industries, including automotive, aerospace, and manufacturing.

What are the career prospects for Tool Engineers?

Tool Engineers with strong skills and experience can advance to leadership positions, such as Tooling Manager or Chief Tool Engineer.

What are the educational requirements for becoming a Tool Engineer?

Most Tool Engineers hold a Bachelor’s Degree in Tool Engineering or a related field, such as Mechanical Engineering.

What are the typical responsibilities of a Tool Engineer?

Typical responsibilities include designing and developing tooling systems, optimizing tooling performance, and troubleshooting production issues.

What are the challenges faced by Tool Engineers?

Tool Engineers often face challenges related to meeting production demands, improving efficiency, and staying abreast of technological advancements.

What are the key trends in the Tool Engineering industry?

Key trends include the adoption of additive manufacturing, the use of simulation software, and the integration of Industry 4.0 technologies.

What are the professional development opportunities for Tool Engineers?

Tool Engineers can pursue professional development opportunities through certifications, workshops, and conferences.