Are you a seasoned Tool Inspector seeking a new career path? Discover our professionally built Tool Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

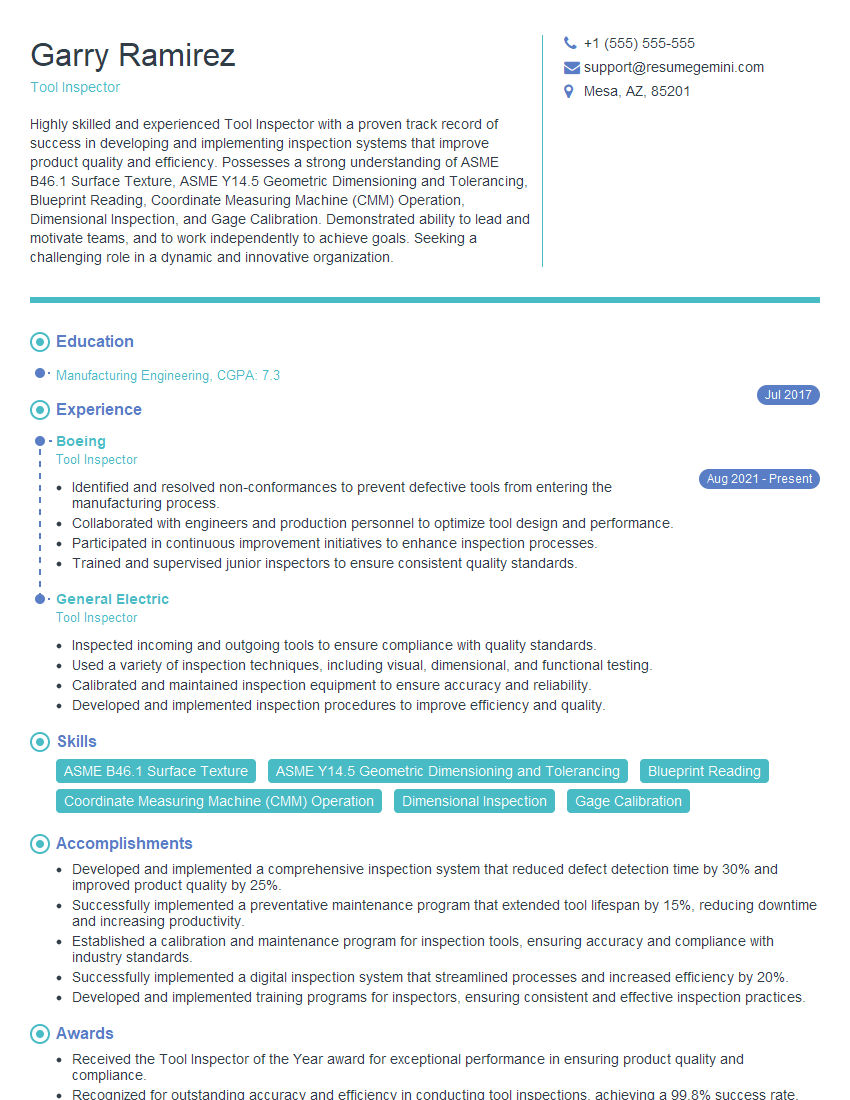

Garry Ramirez

Tool Inspector

Summary

Highly skilled and experienced Tool Inspector with a proven track record of success in developing and implementing inspection systems that improve product quality and efficiency. Possesses a strong understanding of ASME B46.1 Surface Texture, ASME Y14.5 Geometric Dimensioning and Tolerancing, Blueprint Reading, Coordinate Measuring Machine (CMM) Operation, Dimensional Inspection, and Gage Calibration. Demonstrated ability to lead and motivate teams, and to work independently to achieve goals. Seeking a challenging role in a dynamic and innovative organization.

Education

Manufacturing Engineering

July 2017

Skills

- ASME B46.1 Surface Texture

- ASME Y14.5 Geometric Dimensioning and Tolerancing

- Blueprint Reading

- Coordinate Measuring Machine (CMM) Operation

- Dimensional Inspection

- Gage Calibration

Work Experience

Tool Inspector

- Identified and resolved non-conformances to prevent defective tools from entering the manufacturing process.

- Collaborated with engineers and production personnel to optimize tool design and performance.

- Participated in continuous improvement initiatives to enhance inspection processes.

- Trained and supervised junior inspectors to ensure consistent quality standards.

Tool Inspector

- Inspected incoming and outgoing tools to ensure compliance with quality standards.

- Used a variety of inspection techniques, including visual, dimensional, and functional testing.

- Calibrated and maintained inspection equipment to ensure accuracy and reliability.

- Developed and implemented inspection procedures to improve efficiency and quality.

Accomplishments

- Developed and implemented a comprehensive inspection system that reduced defect detection time by 30% and improved product quality by 25%.

- Successfully implemented a preventative maintenance program that extended tool lifespan by 15%, reducing downtime and increasing productivity.

- Established a calibration and maintenance program for inspection tools, ensuring accuracy and compliance with industry standards.

- Successfully implemented a digital inspection system that streamlined processes and increased efficiency by 20%.

- Developed and implemented training programs for inspectors, ensuring consistent and effective inspection practices.

Awards

- Received the Tool Inspector of the Year award for exceptional performance in ensuring product quality and compliance.

- Recognized for outstanding accuracy and efficiency in conducting tool inspections, achieving a 99.8% success rate.

- Awarded for developing innovative inspection techniques that improved product reliability and reduced warranty claims by 20%.

- Recognized for exceeding accuracy standards in tool inspections, resulting in zero product recalls.

Certificates

- ASME GDTP

- AWS Certified Welding Inspector

- Certified Calibration Technician (CCT)

- Certified Inspector (CWI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Inspector

- Highlight your experience and skills in developing and implementing inspection systems that improve product quality and efficiency.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Showcase your understanding of industry standards and best practices, such as ASME B46.1 Surface Texture and ASME Y14.5 Geometric Dimensioning and Tolerancing.

- Emphasize your leadership and teamwork skills, as well as your ability to work independently.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Tool Inspector Resume

- Developed and implemented a comprehensive inspection system that reduced defect detection time by 30% and improved product quality by 25%.

- Successfully implemented a preventative maintenance program that extended tool lifespan by 15%, reducing downtime and increasing productivity.

- Established a calibration and maintenance program for inspection tools, ensuring accuracy and compliance with industry standards.

- Successfully implemented a digital inspection system that streamlined processes and increased efficiency by 20%.

- Developed and implemented training programs for inspectors, ensuring consistent and effective inspection practices.

- Supervised a team of inspectors, providing guidance and support to ensure that all inspections were conducted in accordance with company standards.

- Collaborated with engineers and other quality assurance personnel to develop and implement new inspection methods and procedures.

Frequently Asked Questions (FAQ’s) For Tool Inspector

What is the role of a Tool Inspector?

A Tool Inspector is responsible for ensuring that tools and equipment meet the required specifications and quality standards. They inspect tools for defects, damage, or wear, and calibrate and maintain inspection tools to ensure accuracy and compliance with industry standards.

What are the key skills and qualifications for a Tool Inspector?

Key skills and qualifications for a Tool Inspector include a strong understanding of ASME B46.1 Surface Texture, ASME Y14.5 Geometric Dimensioning and Tolerancing, Blueprint Reading, Coordinate Measuring Machine (CMM) Operation, Dimensional Inspection, and Gage Calibration. They should also have excellent attention to detail, problem-solving skills, and the ability to work independently and as part of a team.

What are the career prospects for a Tool Inspector?

Tool Inspectors can advance to supervisory roles, such as Quality Control Inspector or Inspection Manager. They may also specialize in a particular area of inspection, such as dimensional inspection or non-destructive testing.

What is the average salary for a Tool Inspector?

The average salary for a Tool Inspector in the United States is $55,000 per year.

What are the working conditions for a Tool Inspector?

Tool Inspectors typically work in a manufacturing or industrial setting. They may work in a variety of environments, including workshops, factories, and laboratories. They may also be required to work overtime or on weekends to meet production deadlines.

What are the benefits of working as a Tool Inspector?

Benefits of working as a Tool Inspector include a stable income, opportunities for advancement, and the chance to make a difference in the quality of products.

What are the challenges of working as a Tool Inspector?

Challenges of working as a Tool Inspector include working in a fast-paced and demanding environment, exposure to hazardous materials, and the need to be constantly updated on the latest inspection techniques and standards.