Are you a seasoned Tool Machine Shop Supervisor seeking a new career path? Discover our professionally built Tool Machine Shop Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

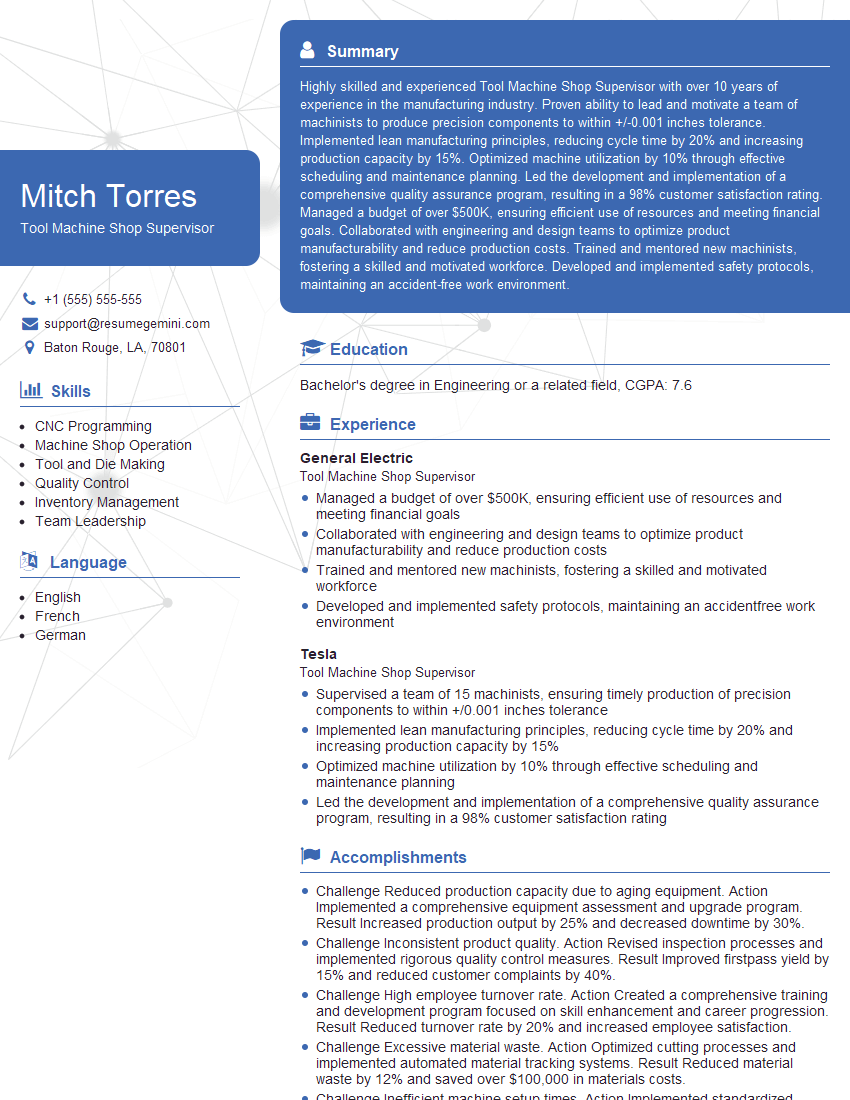

Mitch Torres

Tool Machine Shop Supervisor

Summary

Highly skilled and experienced Tool Machine Shop Supervisor with over 10 years of experience in the manufacturing industry. Proven ability to lead and motivate a team of machinists to produce precision components to within +/-0.001 inches tolerance. Implemented lean manufacturing principles, reducing cycle time by 20% and increasing production capacity by 15%. Optimized machine utilization by 10% through effective scheduling and maintenance planning. Led the development and implementation of a comprehensive quality assurance program, resulting in a 98% customer satisfaction rating. Managed a budget of over $500K, ensuring efficient use of resources and meeting financial goals. Collaborated with engineering and design teams to optimize product manufacturability and reduce production costs. Trained and mentored new machinists, fostering a skilled and motivated workforce. Developed and implemented safety protocols, maintaining an accident-free work environment.

Education

Bachelor’s degree in Engineering or a related field

March 2017

Skills

- CNC Programming

- Machine Shop Operation

- Tool and Die Making

- Quality Control

- Inventory Management

- Team Leadership

Work Experience

Tool Machine Shop Supervisor

- Managed a budget of over $500K, ensuring efficient use of resources and meeting financial goals

- Collaborated with engineering and design teams to optimize product manufacturability and reduce production costs

- Trained and mentored new machinists, fostering a skilled and motivated workforce

- Developed and implemented safety protocols, maintaining an accidentfree work environment

Tool Machine Shop Supervisor

- Supervised a team of 15 machinists, ensuring timely production of precision components to within +/0.001 inches tolerance

- Implemented lean manufacturing principles, reducing cycle time by 20% and increasing production capacity by 15%

- Optimized machine utilization by 10% through effective scheduling and maintenance planning

- Led the development and implementation of a comprehensive quality assurance program, resulting in a 98% customer satisfaction rating

Accomplishments

- Challenge Reduced production capacity due to aging equipment. Action Implemented a comprehensive equipment assessment and upgrade program. Result Increased production output by 25% and decreased downtime by 30%.

- Challenge Inconsistent product quality. Action Revised inspection processes and implemented rigorous quality control measures. Result Improved firstpass yield by 15% and reduced customer complaints by 40%.

- Challenge High employee turnover rate. Action Created a comprehensive training and development program focused on skill enhancement and career progression. Result Reduced turnover rate by 20% and increased employee satisfaction.

- Challenge Excessive material waste. Action Optimized cutting processes and implemented automated material tracking systems. Result Reduced material waste by 12% and saved over $100,000 in materials costs.

- Challenge Inefficient machine setup times. Action Implemented standardized setup procedures and incorporated quickrelease tooling. Result Reduced machine setup time by 20% and increased machine utilization.

Awards

- National Tooling and Machining Association (NTMA) Excellence in Manufacturing Award for innovative tooling design and implementation.

- American Society for Quality (ASQ) Certified Quality Engineer (CQE) certification, demonstrating expertise in quality management systems.

- Society of Manufacturing Engineers (SME) Outstanding Contribution Award for significant contributions to the advancement of manufacturing technology.

- National Institute for Metalworking Skills (NIMS) Certified Manufacturing Technologist (CMfgT) certification, indicating proficiency in manufacturing operations.

Certificates

- Certified Tooling Engineer (CTE)

- Master Toolmaker (MTM)

- Certified Manufacturing Technician (CMT)

- Certified Six Sigma Green Belt (CSSGB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Machine Shop Supervisor

- Highlight your experience in leading and motivating a team of machinists.

- Quantify your accomplishments using specific metrics, such as reducing cycle time or increasing production capacity.

- Demonstrate your knowledge of lean manufacturing principles and their application in the workplace.

- Emphasize your ability to develop and implement quality assurance programs.

- Showcase your skills in managing a budget and ensuring efficient use of resources.

Essential Experience Highlights for a Strong Tool Machine Shop Supervisor Resume

- Supervise and lead a team of machinists in the production of precision components.

- Implement lean manufacturing principles to improve efficiency and productivity.

- Optimize machine utilization through effective scheduling and maintenance planning.

- Develop and implement quality assurance programs to ensure product quality.

- Manage a budget and ensure efficient use of resources.

- Collaborate with engineering and design teams to optimize product manufacturability.

- Train and mentor new machinists to develop a skilled and motivated workforce.

Frequently Asked Questions (FAQ’s) For Tool Machine Shop Supervisor

What are the key skills required for a Tool Machine Shop Supervisor?

The key skills required for a Tool Machine Shop Supervisor include CNC programming, machine shop operation, tool and die making, quality control, inventory management, and team leadership.

What is the average salary for a Tool Machine Shop Supervisor?

The average salary for a Tool Machine Shop Supervisor in the United States is around $75,000 per year.

What are the career prospects for a Tool Machine Shop Supervisor?

The career prospects for a Tool Machine Shop Supervisor are good. With experience, a Tool Machine Shop Supervisor can advance to positions such as Production Manager, Plant Manager, or even Vice President of Operations.

What are the challenges of being a Tool Machine Shop Supervisor?

The challenges of being a Tool Machine Shop Supervisor include managing a team of employees, meeting production deadlines, and ensuring the quality of products.

What are the rewards of being a Tool Machine Shop Supervisor?

The rewards of being a Tool Machine Shop Supervisor include a good salary, job security, and the opportunity to make a difference in the manufacturing industry.

What is the work environment of a Tool Machine Shop Supervisor?

The work environment of a Tool Machine Shop Supervisor is typically a factory or manufacturing plant. The work can be physically demanding and may involve working with heavy machinery.

What are the hours of a Tool Machine Shop Supervisor?

The hours of a Tool Machine Shop Supervisor can vary depending on the company and the industry. However, most Tool Machine Shop Supervisors work full-time, and some may be required to work overtime.

What is the job outlook for a Tool Machine Shop Supervisor?

The job outlook for a Tool Machine Shop Supervisor is expected to be good over the next few years. The demand for skilled machinists is expected to increase as the manufacturing industry continues to grow.