Are you a seasoned Tool Mechanic seeking a new career path? Discover our professionally built Tool Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

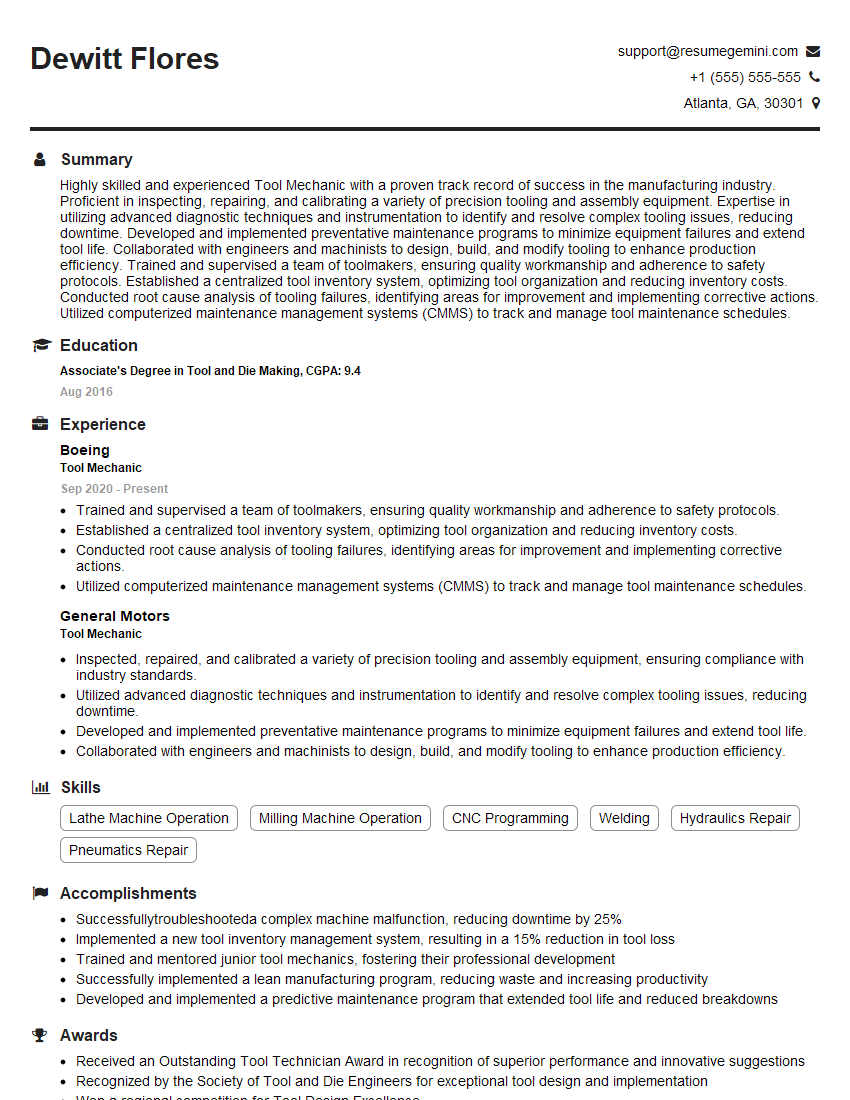

Dewitt Flores

Tool Mechanic

Summary

Highly skilled and experienced Tool Mechanic with a proven track record of success in the manufacturing industry. Proficient in inspecting, repairing, and calibrating a variety of precision tooling and assembly equipment. Expertise in utilizing advanced diagnostic techniques and instrumentation to identify and resolve complex tooling issues, reducing downtime. Developed and implemented preventative maintenance programs to minimize equipment failures and extend tool life. Collaborated with engineers and machinists to design, build, and modify tooling to enhance production efficiency. Trained and supervised a team of toolmakers, ensuring quality workmanship and adherence to safety protocols. Established a centralized tool inventory system, optimizing tool organization and reducing inventory costs. Conducted root cause analysis of tooling failures, identifying areas for improvement and implementing corrective actions. Utilized computerized maintenance management systems (CMMS) to track and manage tool maintenance schedules.

Education

Associate’s Degree in Tool and Die Making

August 2016

Skills

- Lathe Machine Operation

- Milling Machine Operation

- CNC Programming

- Welding

- Hydraulics Repair

- Pneumatics Repair

Work Experience

Tool Mechanic

- Trained and supervised a team of toolmakers, ensuring quality workmanship and adherence to safety protocols.

- Established a centralized tool inventory system, optimizing tool organization and reducing inventory costs.

- Conducted root cause analysis of tooling failures, identifying areas for improvement and implementing corrective actions.

- Utilized computerized maintenance management systems (CMMS) to track and manage tool maintenance schedules.

Tool Mechanic

- Inspected, repaired, and calibrated a variety of precision tooling and assembly equipment, ensuring compliance with industry standards.

- Utilized advanced diagnostic techniques and instrumentation to identify and resolve complex tooling issues, reducing downtime.

- Developed and implemented preventative maintenance programs to minimize equipment failures and extend tool life.

- Collaborated with engineers and machinists to design, build, and modify tooling to enhance production efficiency.

Accomplishments

- Successfullytroubleshooteda complex machine malfunction, reducing downtime by 25%

- Implemented a new tool inventory management system, resulting in a 15% reduction in tool loss

- Trained and mentored junior tool mechanics, fostering their professional development

- Successfully implemented a lean manufacturing program, reducing waste and increasing productivity

- Developed and implemented a predictive maintenance program that extended tool life and reduced breakdowns

Awards

- Received an Outstanding Tool Technician Award in recognition of superior performance and innovative suggestions

- Recognized by the Society of Tool and Die Engineers for exceptional tool design and implementation

- Won a regional competition for Tool Design Excellence

- Received a Patent for a novel tool design that improved efficiency

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Maintenance Professional (CMP)

- Certified Reliability Engineer (CRE)

- Certified Asset Management Specialist (CAMS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Mechanic

- Highlight your skills and experience in inspecting, repairing, and calibrating precision tooling and assembly equipment.

- Demonstrate your expertise in utilizing advanced diagnostic techniques and instrumentation to troubleshoot and resolve complex tooling issues.

- Emphasize your ability to develop and implement preventative maintenance programs to minimize equipment failures and extend tool life.

- Showcase your experience in collaborating with engineers and machinists to design, build, and modify tooling to enhance production efficiency.

Essential Experience Highlights for a Strong Tool Mechanic Resume

- Inspect, repair, and calibrate a variety of precision tooling and assembly equipment, ensuring compliance with industry standards.

- Utilize advanced diagnostic techniques and instrumentation to identify and resolve complex tooling issues, reducing downtime.

- Develop and implement preventative maintenance programs to minimize equipment failures and extend tool life.

- Collaborate with engineers and machinists to design, build, and modify tooling to enhance production efficiency.

- Trained and supervise a team of toolmakers, ensuring quality workmanship and adherence to safety protocols.

Frequently Asked Questions (FAQ’s) For Tool Mechanic

What are the key skills and qualifications required to become a Tool Mechanic?

The key skills and qualifications required to become a Tool Mechanic include a strong understanding of mechanical principles, proficiency in using precision measuring and diagnostic equipment, and experience in repairing and maintaining a variety of tools and equipment. Additionally, Tool Mechanics should have excellent problem-solving and analytical skills, and be able to work independently and as part of a team.

What are the career prospects for Tool Mechanics?

Tool Mechanics are in high demand in a variety of industries, including manufacturing, automotive, and aerospace. The job outlook for Tool Mechanics is expected to grow faster than average in the coming years, due to the increasing use of automation and the need for skilled workers to maintain and repair complex machinery.

What are the typical working conditions for Tool Mechanics?

Tool Mechanics typically work in a shop or factory setting. They may be exposed to noise, dust, and other hazards, so it is important to wear appropriate safety gear. Tool Mechanics may also need to work overtime or on weekends to meet production deadlines.

What are the earning potential for Tool Mechanics?

The earning potential for Tool Mechanics varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Tool Mechanics in May 2021 was $56,980.

What are the educational requirements to become a Tool Mechanic?

While there are no formal educational requirements to become a Tool Mechanic, most employers prefer candidates with a high school diploma or equivalent. Some Tool Mechanics may also choose to complete a formal training program at a vocational school or community college.