Are you a seasoned Tool Planner seeking a new career path? Discover our professionally built Tool Planner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

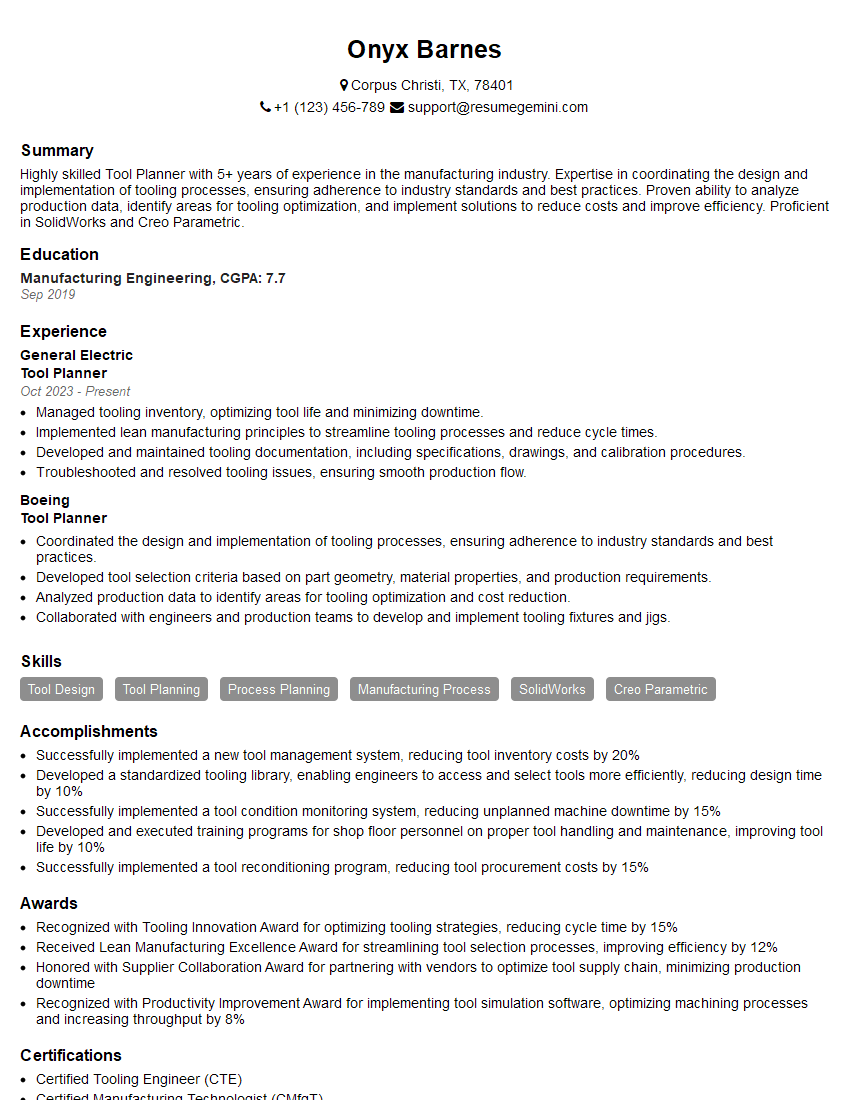

Onyx Barnes

Tool Planner

Summary

Highly skilled Tool Planner with 5+ years of experience in the manufacturing industry. Expertise in coordinating the design and implementation of tooling processes, ensuring adherence to industry standards and best practices. Proven ability to analyze production data, identify areas for tooling optimization, and implement solutions to reduce costs and improve efficiency. Proficient in SolidWorks and Creo Parametric.

Education

Manufacturing Engineering

September 2019

Skills

- Tool Design

- Tool Planning

- Process Planning

- Manufacturing Process

- SolidWorks

- Creo Parametric

Work Experience

Tool Planner

- Managed tooling inventory, optimizing tool life and minimizing downtime.

- Implemented lean manufacturing principles to streamline tooling processes and reduce cycle times.

- Developed and maintained tooling documentation, including specifications, drawings, and calibration procedures.

- Troubleshooted and resolved tooling issues, ensuring smooth production flow.

Tool Planner

- Coordinated the design and implementation of tooling processes, ensuring adherence to industry standards and best practices.

- Developed tool selection criteria based on part geometry, material properties, and production requirements.

- Analyzed production data to identify areas for tooling optimization and cost reduction.

- Collaborated with engineers and production teams to develop and implement tooling fixtures and jigs.

Accomplishments

- Successfully implemented a new tool management system, reducing tool inventory costs by 20%

- Developed a standardized tooling library, enabling engineers to access and select tools more efficiently, reducing design time by 10%

- Successfully implemented a tool condition monitoring system, reducing unplanned machine downtime by 15%

- Developed and executed training programs for shop floor personnel on proper tool handling and maintenance, improving tool life by 10%

- Successfully implemented a tool reconditioning program, reducing tool procurement costs by 15%

Awards

- Recognized with Tooling Innovation Award for optimizing tooling strategies, reducing cycle time by 15%

- Received Lean Manufacturing Excellence Award for streamlining tool selection processes, improving efficiency by 12%

- Honored with Supplier Collaboration Award for partnering with vendors to optimize tool supply chain, minimizing production downtime

- Recognized with Productivity Improvement Award for implementing tool simulation software, optimizing machining processes and increasing throughput by 8%

Certificates

- Certified Tooling Engineer (CTE)

- Certified Manufacturing Technologist (CMfgT)

- Certified Quality Engineer (CQE)

- Certified Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Planner

- Highlight your technical skills in Tool Design, Tool Planning, Process Planning, and Manufacturing Process.

- Showcase your experience in using SolidWorks and Creo Parametric for tooling design and optimization.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Tool Planner Resume

- Coordinated the design and implementation of tooling processes, ensuring adherence to industry standards and best practices.

- Developed tool selection criteria based on part geometry, material properties, and production requirements.

- Collaborated with engineers and production teams to develop and implement tooling fixtures and jigs.

- Managed tooling inventory, optimizing tool life and minimizing downtime.

Frequently Asked Questions (FAQ’s) For Tool Planner

What is the role of a Tool Planner?

A Tool Planner is responsible for the design, implementation, and maintenance of tooling processes within a manufacturing organization. They work closely with engineers and production teams to ensure that tooling is optimized for efficiency, cost-effectiveness, and quality.

What are the key skills required for a Tool Planner?

The key skills required for a Tool Planner include Tool Design, Tool Planning, Process Planning, Manufacturing Process, SolidWorks, and Creo Parametric.

What is the career path for a Tool Planner?

A Tool Planner can advance to roles such as Manufacturing Engineer, Production Manager, or even Plant Manager. With experience and additional education, they can also move into management or consulting roles.

What is the job outlook for Tool Planners?

The job outlook for Tool Planners is expected to be positive in the coming years. The growing manufacturing industry is expected to drive demand for skilled Tool Planners.

What are the challenges faced by Tool Planners?

Tool Planners face challenges such as keeping up with the latest technology, optimizing tooling processes for efficiency, and meeting the demands of production teams.