Are you a seasoned Tool Room Supervisor seeking a new career path? Discover our professionally built Tool Room Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

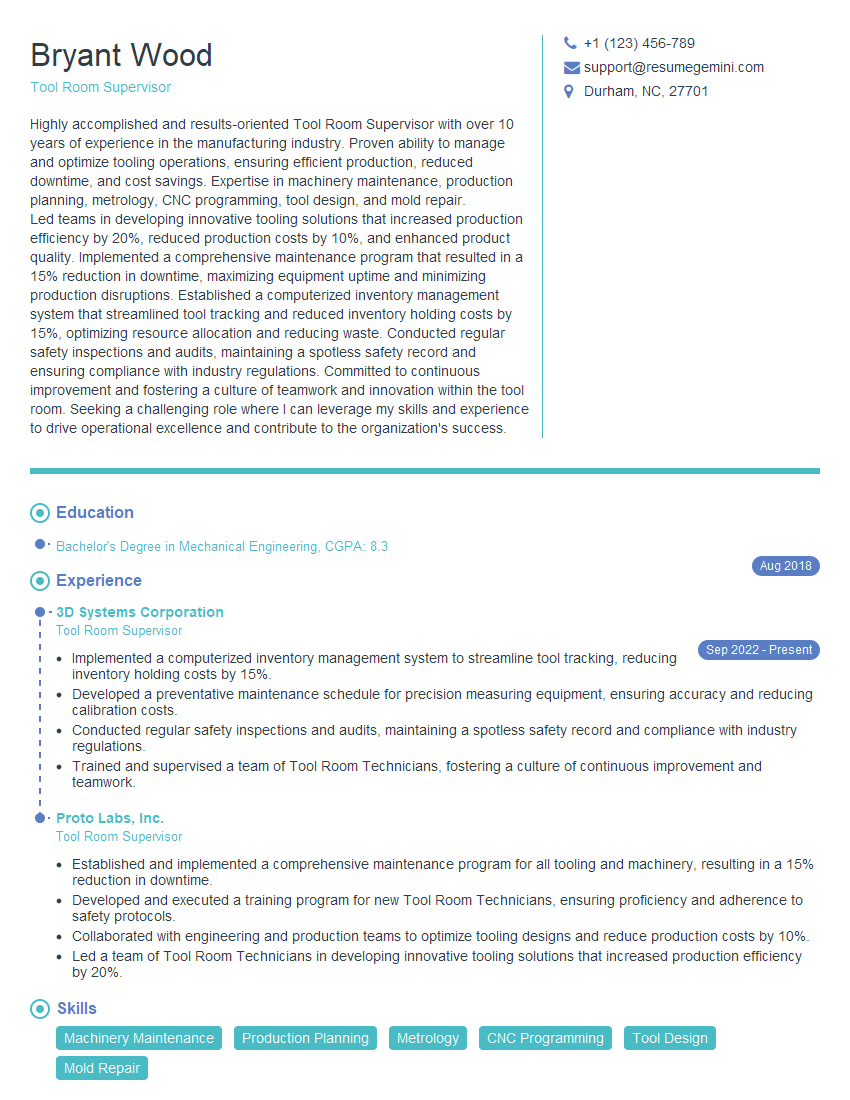

Bryant Wood

Tool Room Supervisor

Summary

Highly accomplished and results-oriented Tool Room Supervisor with over 10 years of experience in the manufacturing industry. Proven ability to manage and optimize tooling operations, ensuring efficient production, reduced downtime, and cost savings. Expertise in machinery maintenance, production planning, metrology, CNC programming, tool design, and mold repair.

Led teams in developing innovative tooling solutions that increased production efficiency by 20%, reduced production costs by 10%, and enhanced product quality. Implemented a comprehensive maintenance program that resulted in a 15% reduction in downtime, maximizing equipment uptime and minimizing production disruptions. Established a computerized inventory management system that streamlined tool tracking and reduced inventory holding costs by 15%, optimizing resource allocation and reducing waste. Conducted regular safety inspections and audits, maintaining a spotless safety record and ensuring compliance with industry regulations. Committed to continuous improvement and fostering a culture of teamwork and innovation within the tool room. Seeking a challenging role where I can leverage my skills and experience to drive operational excellence and contribute to the organization’s success.

Education

Bachelor’s Degree in Mechanical Engineering

August 2018

Skills

- Machinery Maintenance

- Production Planning

- Metrology

- CNC Programming

- Tool Design

- Mold Repair

Work Experience

Tool Room Supervisor

- Implemented a computerized inventory management system to streamline tool tracking, reducing inventory holding costs by 15%.

- Developed a preventative maintenance schedule for precision measuring equipment, ensuring accuracy and reducing calibration costs.

- Conducted regular safety inspections and audits, maintaining a spotless safety record and compliance with industry regulations.

- Trained and supervised a team of Tool Room Technicians, fostering a culture of continuous improvement and teamwork.

Tool Room Supervisor

- Established and implemented a comprehensive maintenance program for all tooling and machinery, resulting in a 15% reduction in downtime.

- Developed and executed a training program for new Tool Room Technicians, ensuring proficiency and adherence to safety protocols.

- Collaborated with engineering and production teams to optimize tooling designs and reduce production costs by 10%.

- Led a team of Tool Room Technicians in developing innovative tooling solutions that increased production efficiency by 20%.

Accomplishments

- Successfully implemented a new tool management system, reducing tool downtime by 35% and increasing productivity.

- Developed and implemented a training program for new tool room employees, resulting in a 20% reduction in toolrelated injuries.

- Led a team to reduce tool inventory costs by 15% through optimized purchasing and inventory management.

- Implemented a preventive maintenance program that extended the lifespan of critical machinery by 25%.

- Successfully implemented a new tool calibration process, ensuring accuracy and compliance with ISO standards.

Certificates

- Certified Tool and Die Maker

- Certified Plastic Injection Mold Designer

- Certified CNC Programmer

- Certified Quality Control Inspector

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Room Supervisor

- Highlight your expertise in tool design, machinery maintenance, and production planning.

- Quantify your accomplishments with specific metrics and percentages to demonstrate the impact of your work.

- Showcase your ability to collaborate effectively with engineering and production teams.

- Emphasize your commitment to safety and industry compliance.

Essential Experience Highlights for a Strong Tool Room Supervisor Resume

- Plan, organize, and supervise all aspects of tool room operations, including machinery maintenance, tool design, and production planning

- Collaborate with engineering and production teams to optimize tooling designs and manufacturing processes, ensuring efficient and cost-effective production

- Develop and implement training programs for Tool Room Technicians, ensuring proficiency and adherence to safety protocols

- Conduct regular safety inspections and audits, maintaining a spotless safety record and compliance with industry regulations

- Manage a team of Tool Room Technicians, fostering a culture of continuous improvement and teamwork

- Troubleshoot and resolve tooling issues, minimizing downtime and ensuring smooth production flow

Frequently Asked Questions (FAQ’s) For Tool Room Supervisor

What are the key responsibilities of a Tool Room Supervisor?

The key responsibilities of a Tool Room Supervisor include planning, organizing, and supervising all aspects of tool room operations, collaborating with engineering and production teams to optimize tooling designs and manufacturing processes, developing and implementing training programs for Tool Room Technicians, conducting regular safety inspections and audits, and managing a team of Tool Room Technicians.

What are the qualifications required to become a Tool Room Supervisor?

The qualifications required to become a Tool Room Supervisor typically include a Bachelor’s Degree in Mechanical Engineering or a related field, along with several years of experience in the manufacturing industry, particularly in tooling operations and machinery maintenance. Strong leadership, communication, and problem-solving skills are also essential.

What are the career prospects for a Tool Room Supervisor?

Tool Room Supervisors can advance their careers by taking on additional responsibilities and leadership roles within the manufacturing industry. They may also pursue specialized certifications or higher education to enhance their skills and knowledge. With experience and expertise, Tool Room Supervisors can progress to positions such as Production Manager, Plant Manager, or Operations Manager.

What are the challenges faced by Tool Room Supervisors?

Tool Room Supervisors may face challenges such as managing a large team of technicians, ensuring the efficient operation of machinery, and meeting production deadlines while maintaining quality standards. They may also need to adapt to new technologies and industry trends to stay competitive.

What are the key skills required for a successful Tool Room Supervisor?

Key skills for a successful Tool Room Supervisor include strong leadership and management abilities, technical expertise in tooling operations and machinery maintenance, excellent communication and interpersonal skills, and a commitment to safety and industry compliance.

What are the typical working conditions for a Tool Room Supervisor?

Tool Room Supervisors typically work in manufacturing facilities, overseeing tool room operations and managing a team of technicians. They may work in a fast-paced and physically demanding environment, and may need to work extended hours to meet production deadlines.

What are the earning prospects for a Tool Room Supervisor?

The earning prospects for a Tool Room Supervisor can vary depending on factors such as experience, location, and industry. According to Salary.com, the median salary for Tool Room Supervisors in the United States is around $75,000 per year.