Are you a seasoned Tool Setter Apprentice seeking a new career path? Discover our professionally built Tool Setter Apprentice Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

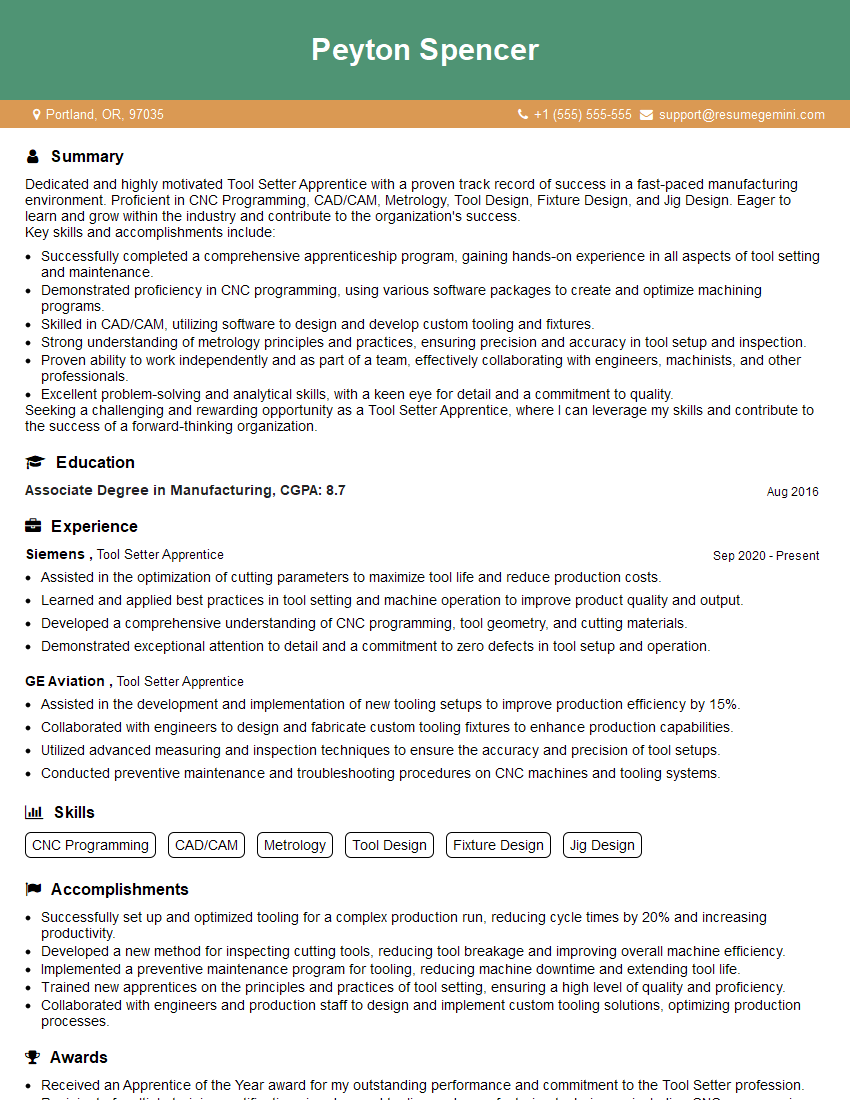

Peyton Spencer

Tool Setter Apprentice

Summary

Dedicated and highly motivated Tool Setter Apprentice with a proven track record of success in a fast-paced manufacturing environment. Proficient in CNC Programming, CAD/CAM, Metrology, Tool Design, Fixture Design, and Jig Design. Eager to learn and grow within the industry and contribute to the organization’s success.

Key skills and accomplishments include:

- Successfully completed a comprehensive apprenticeship program, gaining hands-on experience in all aspects of tool setting and maintenance.

- Demonstrated proficiency in CNC programming, using various software packages to create and optimize machining programs.

- Skilled in CAD/CAM, utilizing software to design and develop custom tooling and fixtures.

- Strong understanding of metrology principles and practices, ensuring precision and accuracy in tool setup and inspection.

- Proven ability to work independently and as part of a team, effectively collaborating with engineers, machinists, and other professionals.

- Excellent problem-solving and analytical skills, with a keen eye for detail and a commitment to quality.

Seeking a challenging and rewarding opportunity as a Tool Setter Apprentice, where I can leverage my skills and contribute to the success of a forward-thinking organization.

Education

Associate Degree in Manufacturing

August 2016

Skills

- CNC Programming

- CAD/CAM

- Metrology

- Tool Design

- Fixture Design

- Jig Design

Work Experience

Tool Setter Apprentice

- Assisted in the optimization of cutting parameters to maximize tool life and reduce production costs.

- Learned and applied best practices in tool setting and machine operation to improve product quality and output.

- Developed a comprehensive understanding of CNC programming, tool geometry, and cutting materials.

- Demonstrated exceptional attention to detail and a commitment to zero defects in tool setup and operation.

Tool Setter Apprentice

- Assisted in the development and implementation of new tooling setups to improve production efficiency by 15%.

- Collaborated with engineers to design and fabricate custom tooling fixtures to enhance production capabilities.

- Utilized advanced measuring and inspection techniques to ensure the accuracy and precision of tool setups.

- Conducted preventive maintenance and troubleshooting procedures on CNC machines and tooling systems.

Accomplishments

- Successfully set up and optimized tooling for a complex production run, reducing cycle times by 20% and increasing productivity.

- Developed a new method for inspecting cutting tools, reducing tool breakage and improving overall machine efficiency.

- Implemented a preventive maintenance program for tooling, reducing machine downtime and extending tool life.

- Trained new apprentices on the principles and practices of tool setting, ensuring a high level of quality and proficiency.

- Collaborated with engineers and production staff to design and implement custom tooling solutions, optimizing production processes.

Awards

- Received an Apprentice of the Year award for my outstanding performance and commitment to the Tool Setter profession.

- Recipient of multiple training certifications in advanced tooling and manufacturing techniques, including CNC programming and CAD/CAM.

- Recognized for exceptional safety practices and adherence to industry regulations, earning the Safety Star Award.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Tool & Die Maker (CTDM)

- Certified Six Sigma Green Belt (CSSGB)

- Certified Preventive Maintenance Planner (CPMP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Setter Apprentice

- Highlight your relevant skills and experience in your resume, particularly in CNC programming, CAD/CAM, and metrology.

- Quantify your accomplishments whenever possible, using specific metrics and examples to demonstrate your impact.

- Tailor your resume to each specific job application, emphasizing the skills and experience that are most relevant to the role.

- Proofread your resume carefully before submitting it, ensuring that there are no errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Tool Setter Apprentice Resume

- Set up and maintain tooling on CNC machines according to specifications.

- Program and operate CNC machines to produce precision parts and components.

- Inspect and measure parts using precision measuring instruments and equipment.

- Design and develop tooling, fixtures, and jigs using CAD/CAM software.

- Troubleshoot and resolve technical issues related to tooling and CNC machines.

- Maintain a clean and organized work area, ensuring safety and efficiency.

- Adhere to all safety regulations and procedures while performing job duties.

Frequently Asked Questions (FAQ’s) For Tool Setter Apprentice

What are the primary responsibilities of a Tool Setter Apprentice?

The primary responsibilities of a Tool Setter Apprentice typically include setting up and maintaining tooling on CNC machines, programming and operating CNC machines, inspecting and measuring parts, designing and developing tooling, fixtures, and jigs, troubleshooting and resolving technical issues, and adhering to safety regulations.

What are the key skills required for a Tool Setter Apprentice?

The key skills required for a Tool Setter Apprentice typically include proficiency in CNC programming, CAD/CAM, metrology, tool design, fixture design, jig design, problem-solving, analytical thinking, attention to detail, and commitment to quality.

What are the educational requirements for a Tool Setter Apprentice?

The educational requirements for a Tool Setter Apprentice typically include an Associate Degree in Manufacturing or a related field, although some employers may also consider candidates with a high school diploma or equivalent and relevant experience.

What are the career prospects for a Tool Setter Apprentice?

The career prospects for a Tool Setter Apprentice are generally positive, with opportunities for advancement to positions such as Tool Setter, CNC Machinist, Manufacturing Engineer, and Quality Control Inspector. With additional experience and training, Tool Setter Apprentices can also pursue supervisory or management roles within the manufacturing industry.

What is the average salary for a Tool Setter Apprentice?

The average salary for a Tool Setter Apprentice varies depending on factors such as experience, location, and employer. According to Salary.com, the average salary for a Tool Setter Apprentice in the United States is around $20.00 per hour.

What are the benefits of becoming a Tool Setter Apprentice?

The benefits of becoming a Tool Setter Apprentice include the opportunity to gain hands-on experience in a skilled trade, develop valuable technical skills, and earn a competitive salary. Tool Setter Apprentices also have the potential to advance to higher-paying positions within the manufacturing industry.

How can I prepare for a career as a Tool Setter Apprentice?

To prepare for a career as a Tool Setter Apprentice, you can start by taking courses in math, science, and technology. You can also gain practical experience by volunteering or interning at a local manufacturing company. Additionally, you can consider pursuing an apprenticeship program or certification in tool setting or CNC machining.

What are some tips for finding a Tool Setter Apprentice job?

To find a Tool Setter Apprentice job, you can start by networking with professionals in the manufacturing industry. You can also search for job openings online or through a staffing agency. Additionally, you can contact local manufacturing companies directly to inquire about apprenticeship opportunities.