Are you a seasoned Tool Shaper Set-Up Operator seeking a new career path? Discover our professionally built Tool Shaper Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

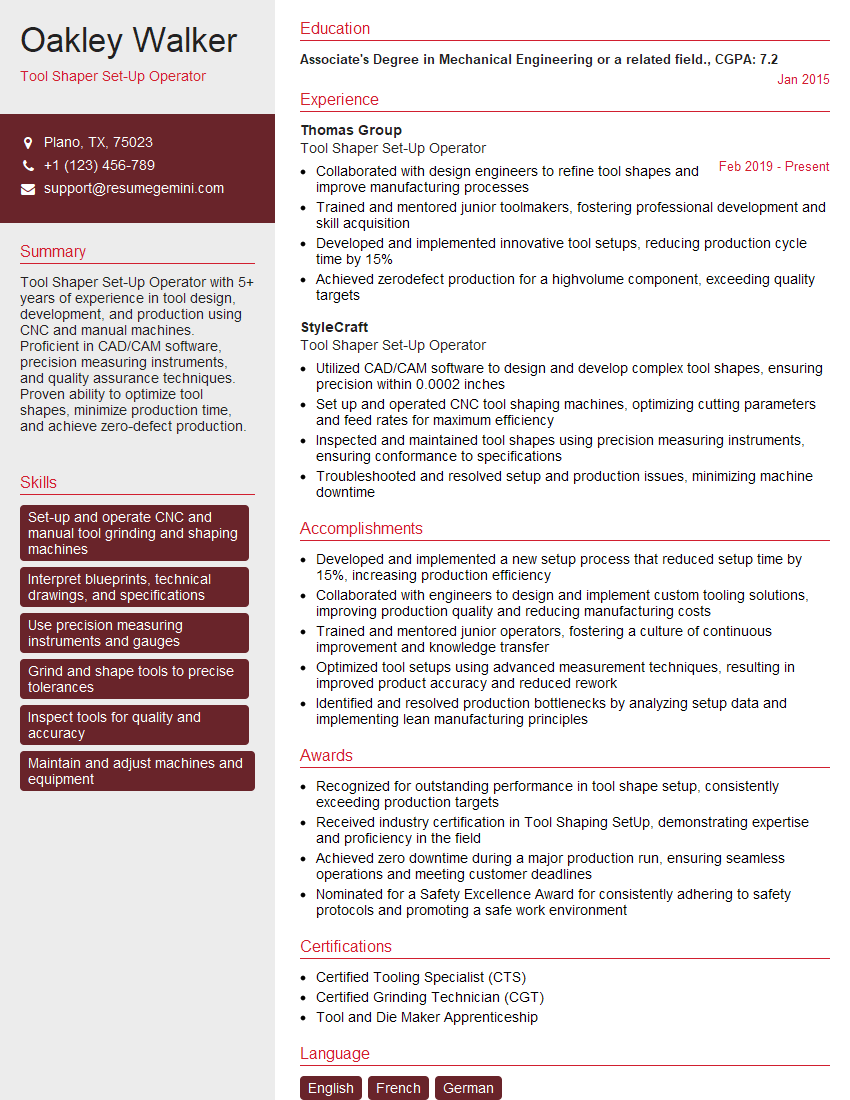

Oakley Walker

Tool Shaper Set-Up Operator

Summary

Tool Shaper Set-Up Operator with 5+ years of experience in tool design, development, and production using CNC and manual machines. Proficient in CAD/CAM software, precision measuring instruments, and quality assurance techniques. Proven ability to optimize tool shapes, minimize production time, and achieve zero-defect production.

Education

Associate’s Degree in Mechanical Engineering or a related field.

January 2015

Skills

- Set-up and operate CNC and manual tool grinding and shaping machines

- Interpret blueprints, technical drawings, and specifications

- Use precision measuring instruments and gauges

- Grind and shape tools to precise tolerances

- Inspect tools for quality and accuracy

- Maintain and adjust machines and equipment

Work Experience

Tool Shaper Set-Up Operator

- Collaborated with design engineers to refine tool shapes and improve manufacturing processes

- Trained and mentored junior toolmakers, fostering professional development and skill acquisition

- Developed and implemented innovative tool setups, reducing production cycle time by 15%

- Achieved zerodefect production for a highvolume component, exceeding quality targets

Tool Shaper Set-Up Operator

- Utilized CAD/CAM software to design and develop complex tool shapes, ensuring precision within 0.0002 inches

- Set up and operated CNC tool shaping machines, optimizing cutting parameters and feed rates for maximum efficiency

- Inspected and maintained tool shapes using precision measuring instruments, ensuring conformance to specifications

- Troubleshooted and resolved setup and production issues, minimizing machine downtime

Accomplishments

- Developed and implemented a new setup process that reduced setup time by 15%, increasing production efficiency

- Collaborated with engineers to design and implement custom tooling solutions, improving production quality and reducing manufacturing costs

- Trained and mentored junior operators, fostering a culture of continuous improvement and knowledge transfer

- Optimized tool setups using advanced measurement techniques, resulting in improved product accuracy and reduced rework

- Identified and resolved production bottlenecks by analyzing setup data and implementing lean manufacturing principles

Awards

- Recognized for outstanding performance in tool shape setup, consistently exceeding production targets

- Received industry certification in Tool Shaping SetUp, demonstrating expertise and proficiency in the field

- Achieved zero downtime during a major production run, ensuring seamless operations and meeting customer deadlines

- Nominated for a Safety Excellence Award for consistently adhering to safety protocols and promoting a safe work environment

Certificates

- Certified Tooling Specialist (CTS)

- Certified Grinding Technician (CGT)

- Tool and Die Maker Apprenticeship

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Shaper Set-Up Operator

- Quantify your accomplishments with specific metrics and results.

- Highlight your experience with different types of CNC machines and software.

- Demonstrate your understanding of tool design and manufacturing principles.

- Proofread your resume carefully for any errors.

- Consider getting feedback from a professional resume writer for further improvement.

Essential Experience Highlights for a Strong Tool Shaper Set-Up Operator Resume

- Set up and operate CNC tool shaping machines to produce custom cutting tools within precise tolerances.

- Utilize CAD/CAM software to design and develop complex tool shapes, ensuring accuracy down to 0.0002 inches.

- Inspect and maintain tools using precision measuring instruments, ensuring conformance to specifications.

- Troubleshoot and resolve setup and production issues, minimizing machine downtime.

- Collaborate with design engineers to refine tool shapes and improve manufacturing processes.

- Develop and implement innovative tool setups, reducing production cycle time.

Frequently Asked Questions (FAQ’s) For Tool Shaper Set-Up Operator

What are the key skills required for a Tool Shaper Set-Up Operator?

Key skills include proficiency in CNC and manual tool shaping machines, CAD/CAM software, precision measuring instruments, and quality assurance techniques.

What are the career prospects for a Tool Shaper Set-Up Operator?

With experience and additional training, Tool Shaper Set-Up Operators can advance to roles such as Tool and Die Maker, CNC Programmer, or Manufacturing Engineer.

What is the average salary for a Tool Shaper Set-Up Operator?

The average salary for a Tool Shaper Set-Up Operator in the United States is around $60,000 per year, but it can vary depending on experience, location, and industry.

What are the working conditions like for a Tool Shaper Set-Up Operator?

Tool Shaper Set-Up Operators typically work in manufacturing environments, which can be noisy and involve exposure to machinery and chemicals. They may also work overtime to meet production deadlines.

How can I prepare for a career as a Tool Shaper Set-Up Operator?

You can prepare for a career as a Tool Shaper Set-Up Operator by completing an Associate’s Degree in Mechanical Engineering or a related field, gaining experience in machining and manufacturing, and obtaining certifications in CNC programming and tool design.