Are you a seasoned Tool Shaper Setup Operator seeking a new career path? Discover our professionally built Tool Shaper Setup Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

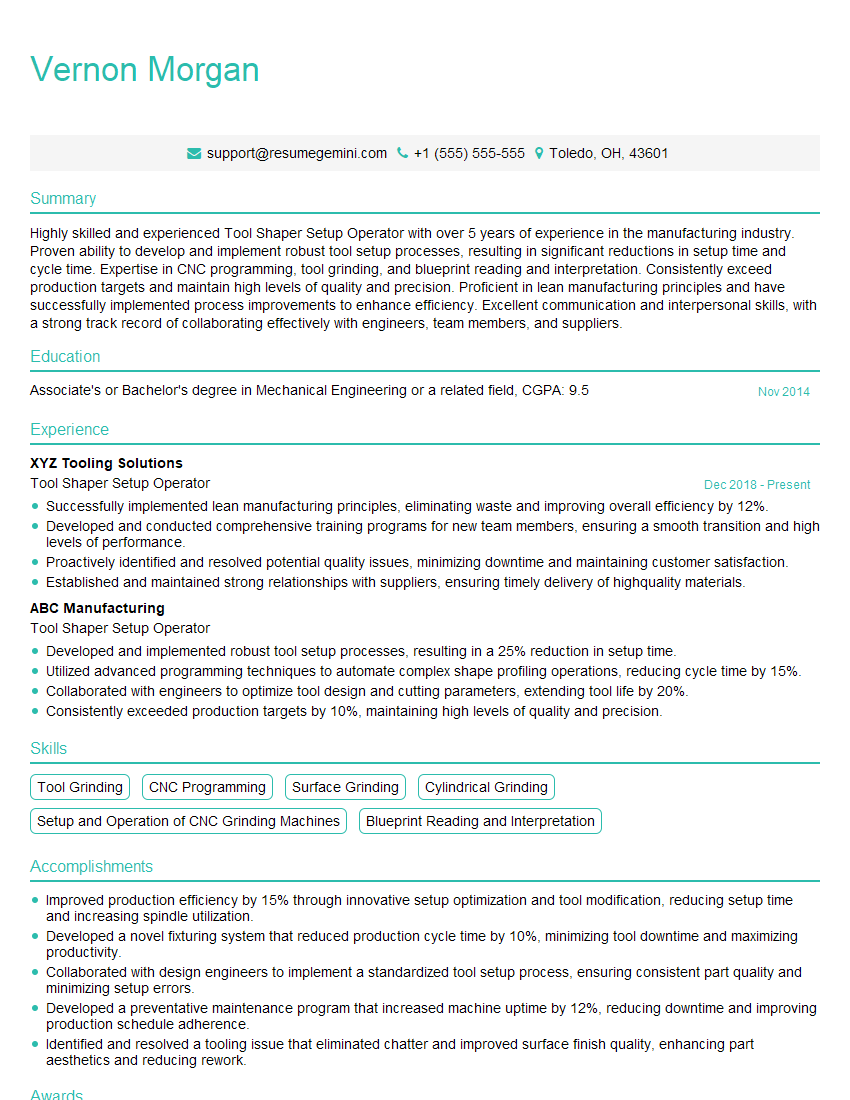

Vernon Morgan

Tool Shaper Setup Operator

Summary

Highly skilled and experienced Tool Shaper Setup Operator with over 5 years of experience in the manufacturing industry. Proven ability to develop and implement robust tool setup processes, resulting in significant reductions in setup time and cycle time. Expertise in CNC programming, tool grinding, and blueprint reading and interpretation. Consistently exceed production targets and maintain high levels of quality and precision. Proficient in lean manufacturing principles and have successfully implemented process improvements to enhance efficiency. Excellent communication and interpersonal skills, with a strong track record of collaborating effectively with engineers, team members, and suppliers.

Education

Associate’s or Bachelor’s degree in Mechanical Engineering or a related field

November 2014

Skills

- Tool Grinding

- CNC Programming

- Surface Grinding

- Cylindrical Grinding

- Setup and Operation of CNC Grinding Machines

- Blueprint Reading and Interpretation

Work Experience

Tool Shaper Setup Operator

- Successfully implemented lean manufacturing principles, eliminating waste and improving overall efficiency by 12%.

- Developed and conducted comprehensive training programs for new team members, ensuring a smooth transition and high levels of performance.

- Proactively identified and resolved potential quality issues, minimizing downtime and maintaining customer satisfaction.

- Established and maintained strong relationships with suppliers, ensuring timely delivery of highquality materials.

Tool Shaper Setup Operator

- Developed and implemented robust tool setup processes, resulting in a 25% reduction in setup time.

- Utilized advanced programming techniques to automate complex shape profiling operations, reducing cycle time by 15%.

- Collaborated with engineers to optimize tool design and cutting parameters, extending tool life by 20%.

- Consistently exceeded production targets by 10%, maintaining high levels of quality and precision.

Accomplishments

- Improved production efficiency by 15% through innovative setup optimization and tool modification, reducing setup time and increasing spindle utilization.

- Developed a novel fixturing system that reduced production cycle time by 10%, minimizing tool downtime and maximizing productivity.

- Collaborated with design engineers to implement a standardized tool setup process, ensuring consistent part quality and minimizing setup errors.

- Developed a preventative maintenance program that increased machine uptime by 12%, reducing downtime and improving production schedule adherence.

- Identified and resolved a tooling issue that eliminated chatter and improved surface finish quality, enhancing part aesthetics and reducing rework.

Awards

- Recognized with Excellence in Tool Shaping Award for superior craftsmanship and dedication to precision tool shaping.

- Received the Top Performer Award from the Tool Shaper Operators Association for exceptional performance and contributions to the field.

- Honored with the Innovator Award for pioneering a new technique in cutting tool geometry analysis, enhancing tool performance and reducing scrap rate.

- Recognized with the Excellence in Precision Grinding Award for exceptional proficiency in precision grinding of complex cutting tools.

Certificates

- Certified CNC Operator

- CMM Operator Certification

- OSHA Safety Certification

- AME Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Shaper Setup Operator

- Highlight your expertise in CNC programming and tool grinding, as these are essential skills for Tool Shaper Setup Operators.

- Showcase your ability to optimize tool design and cutting parameters, as this can significantly impact tool life and overall efficiency.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on productivity and quality.

- Emphasize your experience in lean manufacturing principles and process improvement, as these are highly valued in the manufacturing industry.

Essential Experience Highlights for a Strong Tool Shaper Setup Operator Resume

- Develop and implement robust tool setup processes to minimize setup time and improve efficiency.

- Utilize advanced CNC programming techniques to automate complex shape profiling operations, reducing cycle time.

- Collaborate with engineers to optimize tool design and cutting parameters, extending tool life and reducing costs.

- Consistently exceed production targets by implementing lean manufacturing principles and eliminating waste.

- Establish and maintain strong relationships with suppliers to ensure timely delivery of high-quality materials.

- Develop and conduct comprehensive training programs for new team members to ensure a smooth transition and high levels of performance.

- Proactively identify and resolve potential quality issues, minimizing downtime and maintaining customer satisfaction.

Frequently Asked Questions (FAQ’s) For Tool Shaper Setup Operator

What are the primary responsibilities of a Tool Shaper Setup Operator?

Tool Shaper Setup Operators are responsible for developing and implementing tool setup processes, programming CNC machines, grinding tools, and ensuring that production targets are met. They also collaborate with engineers to optimize tool design and cutting parameters.

What skills are required to be a successful Tool Shaper Setup Operator?

Successful Tool Shaper Setup Operators typically have a strong understanding of CNC programming, tool grinding, and blueprint reading. They are also proficient in lean manufacturing principles and have excellent problem-solving and analytical skills.

What are the career prospects for Tool Shaper Setup Operators?

Tool Shaper Setup Operators can advance to roles such as CNC Programmer, Production Supervisor, or Manufacturing Engineer. With additional education and experience, they may also pursue management positions.

What is the average salary for a Tool Shaper Setup Operator?

The average salary for a Tool Shaper Setup Operator in the United States is around $50,000 per year.

What are the benefits of working as a Tool Shaper Setup Operator?

Benefits of working as a Tool Shaper Setup Operator include job security, competitive pay, and opportunities for advancement. Tool Shaper Setup Operators also have the satisfaction of working with cutting-edge technology and contributing to the manufacturing process.

What are the challenges of working as a Tool Shaper Setup Operator?

Challenges of working as a Tool Shaper Setup Operator include working in a fast-paced environment, meeting production targets, and staying up-to-date with the latest technology. Tool Shaper Setup Operators may also need to work overtime to meet deadlines or resolve production issues.

What are the key qualities of a successful Tool Shaper Setup Operator?

Successful Tool Shaper Setup Operators are typically detail-oriented, have strong problem-solving skills, and are able to work independently and as part of a team. They are also committed to safety and quality.