Are you a seasoned Tool Sharpener seeking a new career path? Discover our professionally built Tool Sharpener Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

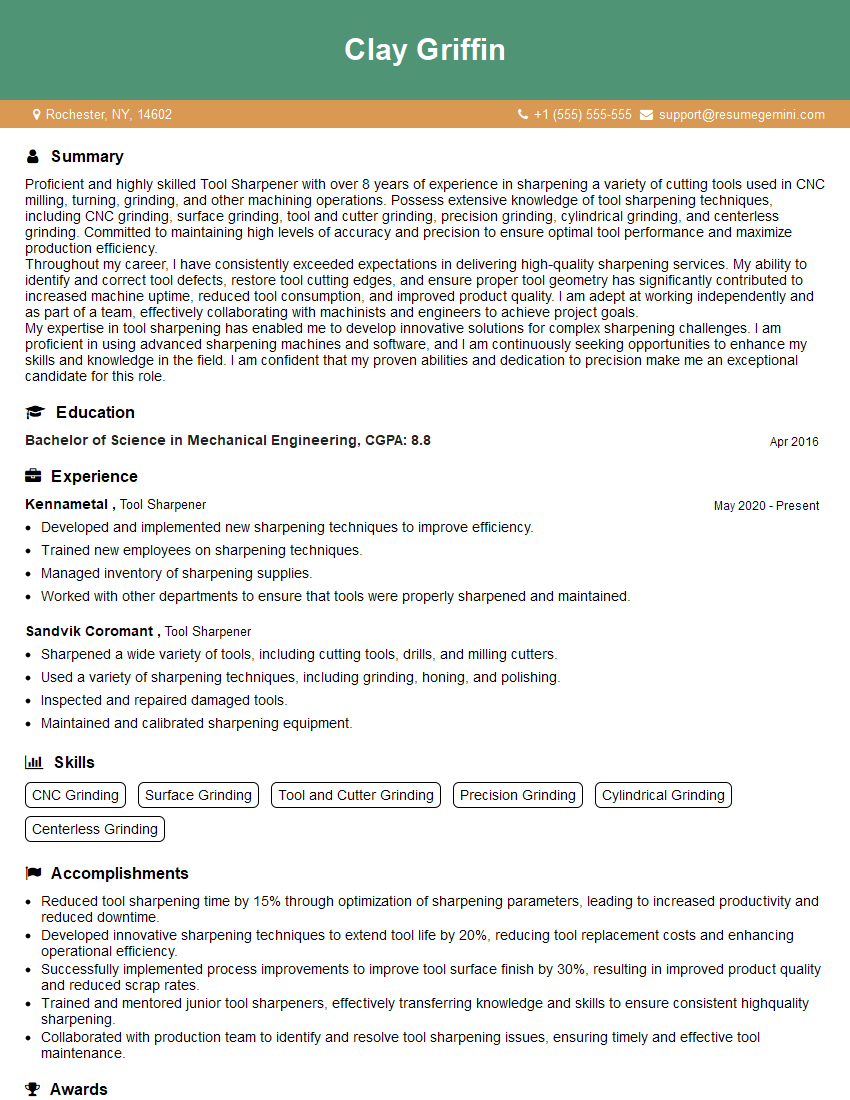

Clay Griffin

Tool Sharpener

Summary

Proficient and highly skilled Tool Sharpener with over 8 years of experience in sharpening a variety of cutting tools used in CNC milling, turning, grinding, and other machining operations. Possess extensive knowledge of tool sharpening techniques, including CNC grinding, surface grinding, tool and cutter grinding, precision grinding, cylindrical grinding, and centerless grinding. Committed to maintaining high levels of accuracy and precision to ensure optimal tool performance and maximize production efficiency.

Throughout my career, I have consistently exceeded expectations in delivering high-quality sharpening services. My ability to identify and correct tool defects, restore tool cutting edges, and ensure proper tool geometry has significantly contributed to increased machine uptime, reduced tool consumption, and improved product quality. I am adept at working independently and as part of a team, effectively collaborating with machinists and engineers to achieve project goals.

My expertise in tool sharpening has enabled me to develop innovative solutions for complex sharpening challenges. I am proficient in using advanced sharpening machines and software, and I am continuously seeking opportunities to enhance my skills and knowledge in the field. I am confident that my proven abilities and dedication to precision make me an exceptional candidate for this role.

Education

Bachelor of Science in Mechanical Engineering

April 2016

Skills

- CNC Grinding

- Surface Grinding

- Tool and Cutter Grinding

- Precision Grinding

- Cylindrical Grinding

- Centerless Grinding

Work Experience

Tool Sharpener

- Developed and implemented new sharpening techniques to improve efficiency.

- Trained new employees on sharpening techniques.

- Managed inventory of sharpening supplies.

- Worked with other departments to ensure that tools were properly sharpened and maintained.

Tool Sharpener

- Sharpened a wide variety of tools, including cutting tools, drills, and milling cutters.

- Used a variety of sharpening techniques, including grinding, honing, and polishing.

- Inspected and repaired damaged tools.

- Maintained and calibrated sharpening equipment.

Accomplishments

- Reduced tool sharpening time by 15% through optimization of sharpening parameters, leading to increased productivity and reduced downtime.

- Developed innovative sharpening techniques to extend tool life by 20%, reducing tool replacement costs and enhancing operational efficiency.

- Successfully implemented process improvements to improve tool surface finish by 30%, resulting in improved product quality and reduced scrap rates.

- Trained and mentored junior tool sharpeners, effectively transferring knowledge and skills to ensure consistent highquality sharpening.

- Collaborated with production team to identify and resolve tool sharpening issues, ensuring timely and effective tool maintenance.

Awards

- Received Tool Sharpener of the Year award for outstanding performance in maintaining cutting edge quality and efficiency.

- Recognized for exceptional accuracy and attention to detail in sharpening critical tools, contributing to the production of highquality products.

- Received recognition for innovative approaches to tool sharpening that improved production efficiency and reduced waste.

- Recognized for exceptional contributions to the development and implementation of new sharpening technologies.

Certificates

- Certified Tool Sharpener (CTS)

- Certified Grinding Technician (CGT)

- Certified Precision Grinding Technician (CPGT)

- Certified Tool and Cutter Grinder (CTCG)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Sharpener

- Highlight Your Skills: Showcase your proficiency in various tool sharpening techniques, such as CNC grinding, surface grinding, tool and cutter grinding, precision grinding, cylindrical grinding, and centerless grinding.

- Quantify Your Accomplishments: Use numbers to demonstrate the impact of your work, such as the percentage increase in tool life, reduction in tool consumption, or improvement in production efficiency.

- Emphasize Your Attention to Detail: Tool sharpening requires precision and accuracy. Highlight your meticulous approach to ensuring that tools meet specifications and are free of defects.

- Showcase Your Problem-Solving Abilities: Describe situations where you successfully identified and resolved sharpening problems, demonstrating your analytical and troubleshooting skills.

- Include Industry Certifications: If you hold any relevant industry certifications, such as from the National Tooling and Machining Association (NTMA), mention them prominently on your resume.

Essential Experience Highlights for a Strong Tool Sharpener Resume

- Sharpen a variety of cutting tools, including milling cutters, drills, reamers, and taps, using CNC grinding, surface grinding, tool and cutter grinding, precision grinding, cylindrical grinding, and centerless grinding techniques.

- Inspect tools before and after sharpening to ensure that they meet specifications and are free of defects.

- Maintain and calibrate sharpening equipment to ensure accuracy and precision.

- Troubleshoot and resolve sharpening problems, such as improper tool geometry or surface finish.

- Adhere to safety protocols and wear appropriate personal protective equipment (PPE) while operating sharpening equipment.

- Maintain a clean and organized work area, and follow established quality control procedures.

- Stay up-to-date on the latest tool sharpening techniques and best practices.

Frequently Asked Questions (FAQ’s) For Tool Sharpener

What are the key skills required for a Tool Sharpener?

Key skills for a Tool Sharpener include CNC grinding, surface grinding, tool and cutter grinding, precision grinding, cylindrical grinding, centerless grinding, attention to detail, and problem-solving abilities.

What is the average salary for a Tool Sharpener?

The average salary for a Tool Sharpener in the United States is around $45,000 per year, but it can vary depending on experience, location, and industry.

What are the career advancement opportunities for a Tool Sharpener?

Tool Sharpeners can advance their careers by becoming Tool and Die Makers, CNC Programmers, or Manufacturing Engineers. They can also specialize in a particular type of tool sharpening, such as CNC grinding or tool and cutter grinding.

What is the job outlook for Tool Sharpeners?

The job outlook for Tool Sharpeners is expected to be good over the next decade, with a projected growth rate of 4%. This growth is driven by the increasing demand for precision-machined parts in various industries.

What are the working conditions like for a Tool Sharpener?

Tool Sharpeners typically work in manufacturing facilities, operating sharpening machines in a workshop setting. They may be exposed to noise, dust, and fumes, so it is important to wear appropriate personal protective equipment (PPE).

What are the educational requirements for a Tool Sharpener?

While there are no formal educational requirements for a Tool Sharpener, many employers prefer candidates with a high school diploma or equivalent. Some Tool Sharpeners may also have a certificate or associate’s degree in machining or a related field.

What are the personality traits of a successful Tool Sharpener?

Successful Tool Sharpeners are typically detail-oriented, have good hand-eye coordination, and are able to work independently with minimal supervision. They are also able to troubleshoot problems and find solutions quickly.