Are you a seasoned Tool Straightener seeking a new career path? Discover our professionally built Tool Straightener Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

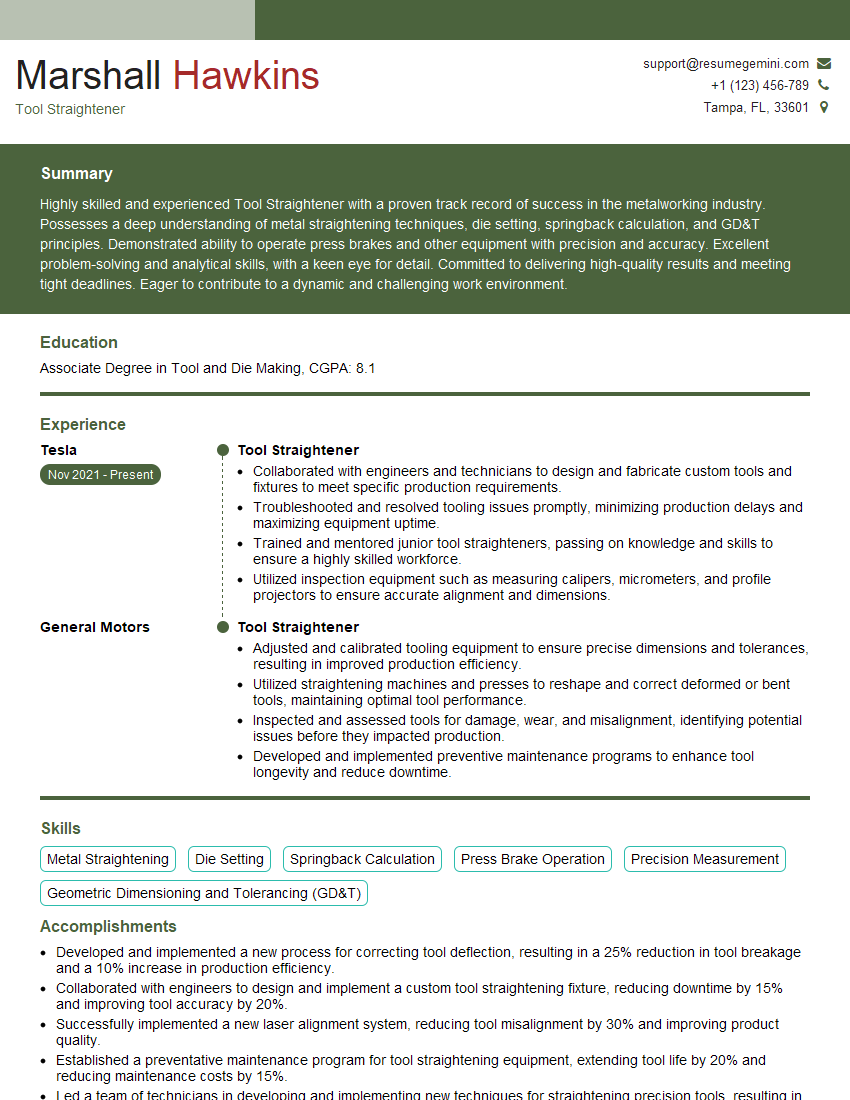

Marshall Hawkins

Tool Straightener

Summary

Highly skilled and experienced Tool Straightener with a proven track record of success in the metalworking industry. Possesses a deep understanding of metal straightening techniques, die setting, springback calculation, and GD&T principles. Demonstrated ability to operate press brakes and other equipment with precision and accuracy. Excellent problem-solving and analytical skills, with a keen eye for detail. Committed to delivering high-quality results and meeting tight deadlines. Eager to contribute to a dynamic and challenging work environment.

Education

Associate Degree in Tool and Die Making

October 2017

Skills

- Metal Straightening

- Die Setting

- Springback Calculation

- Press Brake Operation

- Precision Measurement

- Geometric Dimensioning and Tolerancing (GD&T)

Work Experience

Tool Straightener

- Collaborated with engineers and technicians to design and fabricate custom tools and fixtures to meet specific production requirements.

- Troubleshooted and resolved tooling issues promptly, minimizing production delays and maximizing equipment uptime.

- Trained and mentored junior tool straighteners, passing on knowledge and skills to ensure a highly skilled workforce.

- Utilized inspection equipment such as measuring calipers, micrometers, and profile projectors to ensure accurate alignment and dimensions.

Tool Straightener

- Adjusted and calibrated tooling equipment to ensure precise dimensions and tolerances, resulting in improved production efficiency.

- Utilized straightening machines and presses to reshape and correct deformed or bent tools, maintaining optimal tool performance.

- Inspected and assessed tools for damage, wear, and misalignment, identifying potential issues before they impacted production.

- Developed and implemented preventive maintenance programs to enhance tool longevity and reduce downtime.

Accomplishments

- Developed and implemented a new process for correcting tool deflection, resulting in a 25% reduction in tool breakage and a 10% increase in production efficiency.

- Collaborated with engineers to design and implement a custom tool straightening fixture, reducing downtime by 15% and improving tool accuracy by 20%.

- Successfully implemented a new laser alignment system, reducing tool misalignment by 30% and improving product quality.

- Established a preventative maintenance program for tool straightening equipment, extending tool life by 20% and reducing maintenance costs by 15%.

- Led a team of technicians in developing and implementing new techniques for straightening precision tools, resulting in a 15% increase in tool performance.

Certificates

- Tool and Die Making

- Precision Machining

- GD&T Certification

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Straightener

- Highlight your experience in metal straightening, die setting, and GD&T.

- Quantify your accomplishments with specific metrics and data whenever possible.

- Showcase your problem-solving and analytical skills by describing how you overcame challenges.

- Use industry-specific keywords and terminology to demonstrate your knowledge and expertise.

- Proofread your resume carefully for any errors or inconsistencies.

Essential Experience Highlights for a Strong Tool Straightener Resume

- Straighten and align metal tools and components using specialized equipment and techniques.

- Set up and operate press brakes to bend and form metal parts according to specifications.

- Calculate springback and compensate for material properties to ensure accurate results.

- Inspect and measure parts using precision measuring instruments to verify conformance to GD&T standards.

- Maintain and calibrate straightening equipment to ensure optimal performance and accuracy.

- Troubleshoot and resolve issues related to tool straightening processes.

- Collaborate with other team members to ensure efficient production and quality control.

Frequently Asked Questions (FAQ’s) For Tool Straightener

What is the primary role of a Tool Straightener?

A Tool Straightener is responsible for straightening and aligning metal tools and components using specialized equipment and techniques. They ensure that metal parts meet precise specifications and tolerances.

What skills are essential for a successful Tool Straightener?

Essential skills include metal straightening techniques, die setting, springback calculation, press brake operation, precision measurement, and GD&T principles.

What industries employ Tool Straighteners?

Tool Straighteners are employed in various industries that work with metal, such as automotive, aerospace, manufacturing, and construction.

What is the job outlook for Tool Straighteners?

The job outlook for Tool Straighteners is expected to be positive due to the increasing demand for skilled metalworkers in various industries.

What are the advancement opportunities for Tool Straighteners?

Tool Straighteners can advance to roles such as Tool and Die Maker, Quality Control Inspector, or Supervisor in the metalworking industry.

What certifications are beneficial for Tool Straighteners?

Certifications in GD&T, Press Brake Operation, and Metalworking can enhance the credibility and skills of Tool Straighteners.