Are you a seasoned Tool Technician seeking a new career path? Discover our professionally built Tool Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

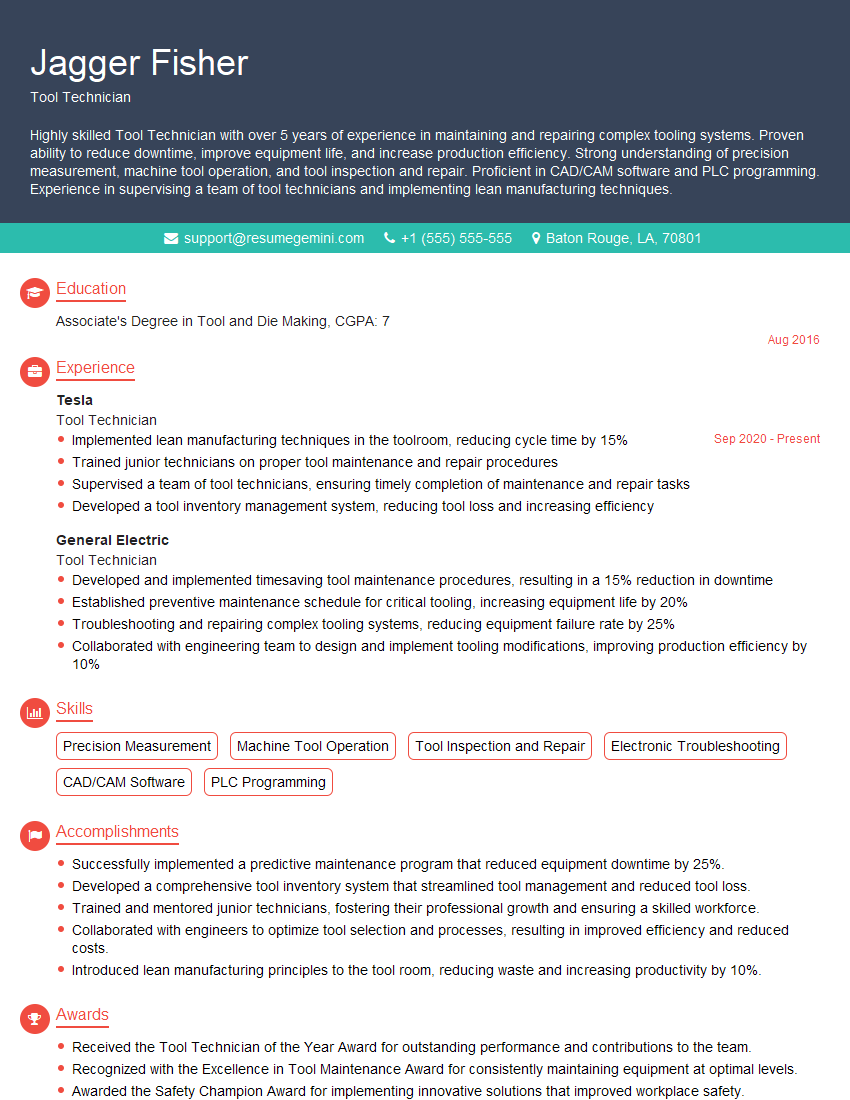

Jagger Fisher

Tool Technician

Summary

Highly skilled Tool Technician with over 5 years of experience in maintaining and repairing complex tooling systems. Proven ability to reduce downtime, improve equipment life, and increase production efficiency. Strong understanding of precision measurement, machine tool operation, and tool inspection and repair. Proficient in CAD/CAM software and PLC programming. Experience in supervising a team of tool technicians and implementing lean manufacturing techniques.

Education

Associate’s Degree in Tool and Die Making

August 2016

Skills

- Precision Measurement

- Machine Tool Operation

- Tool Inspection and Repair

- Electronic Troubleshooting

- CAD/CAM Software

- PLC Programming

Work Experience

Tool Technician

- Implemented lean manufacturing techniques in the toolroom, reducing cycle time by 15%

- Trained junior technicians on proper tool maintenance and repair procedures

- Supervised a team of tool technicians, ensuring timely completion of maintenance and repair tasks

- Developed a tool inventory management system, reducing tool loss and increasing efficiency

Tool Technician

- Developed and implemented timesaving tool maintenance procedures, resulting in a 15% reduction in downtime

- Established preventive maintenance schedule for critical tooling, increasing equipment life by 20%

- Troubleshooting and repairing complex tooling systems, reducing equipment failure rate by 25%

- Collaborated with engineering team to design and implement tooling modifications, improving production efficiency by 10%

Accomplishments

- Successfully implemented a predictive maintenance program that reduced equipment downtime by 25%.

- Developed a comprehensive tool inventory system that streamlined tool management and reduced tool loss.

- Trained and mentored junior technicians, fostering their professional growth and ensuring a skilled workforce.

- Collaborated with engineers to optimize tool selection and processes, resulting in improved efficiency and reduced costs.

- Introduced lean manufacturing principles to the tool room, reducing waste and increasing productivity by 10%.

Awards

- Received the Tool Technician of the Year Award for outstanding performance and contributions to the team.

- Recognized with the Excellence in Tool Maintenance Award for consistently maintaining equipment at optimal levels.

- Awarded the Safety Champion Award for implementing innovative solutions that improved workplace safety.

Certificates

- CNC Machining

- PLC Programming

- Robotics

- Lean Manufacturing

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Technician

- Highlight your skills and experience in precision measurement, machine tool operation, and tool inspection and repair.

- Quantify your accomplishments with specific metrics, such as reducing downtime or increasing production efficiency.

- Demonstrate your knowledge of CAD/CAM software and PLC programming and how you have used them to improve tooling systems.

- Emphasize your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Tool Technician Resume

- Develop and implement timesaving tool maintenance procedures.

- Establish and maintain preventive maintenance schedules for critical tooling.

- Troubleshoot and repair complex tooling systems.

- Collaborate with engineering team to design and implement tooling modifications.

- Implement lean manufacturing techniques to reduce cycle time.

- Train junior technicians on proper tool maintenance and repair procedures.

- Supervise a team of tool technicians and ensure timely completion of maintenance and repair tasks.

Frequently Asked Questions (FAQ’s) For Tool Technician

What are the key skills and qualifications required to become a Tool Technician?

Key skills and qualifications include: precision measurement, machine tool operation, tool inspection and repair, electronic troubleshooting, CAD/CAM software, and PLC programming.

What are the primary responsibilities of a Tool Technician?

Primary responsibilities include: developing and implementing tool maintenance procedures, establishing preventive maintenance schedules, troubleshooting and repairing tooling systems, collaborating with engineering teams, implementing lean manufacturing techniques, training junior technicians, and supervising a team of tool technicians.

What are the career prospects for Tool Technicians?

Career prospects are excellent for Tool Technicians with experience and expertise in precision measurement, machine tool operation, and tool inspection and repair. They can advance to supervisory roles, engineering positions, or management positions.

What is the salary range for Tool Technicians?

The salary range for Tool Technicians varies depending on experience, location, and industry. According to the Bureau of Labor Statistics, the median annual salary for Tool and Die Makers, which includes Tool Technicians, was $52,980 in May 2021.

What are the educational requirements for Tool Technicians?

Most Tool Technicians have an associate’s degree in tool and die making or a related field. Some may also have a high school diploma or equivalent and complete an apprenticeship program.

What are the certification options available for Tool Technicians?

There are several certification options available for Tool Technicians, including: Certified Tooling Specialist (CTS) from the Society of Manufacturing Engineers (SME), Certified Precision Measurement Technician (CPMT) from the American Society for Quality (ASQ), and Certified Manufacturing Technologist (CMfgT) from the Manufacturing Certification Institute (MCI).

What are the industries that employ Tool Technicians?

Tool Technicians are employed in a variety of industries, including: automotive, aerospace, manufacturing, and construction.

What is the job outlook for Tool Technicians?

The job outlook for Tool Technicians is expected to be good over the next decade. As technology advances and manufacturing processes become more complex, the demand for skilled Tool Technicians will continue to grow.