Are you a seasoned Tool Trouble Shooter seeking a new career path? Discover our professionally built Tool Trouble Shooter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

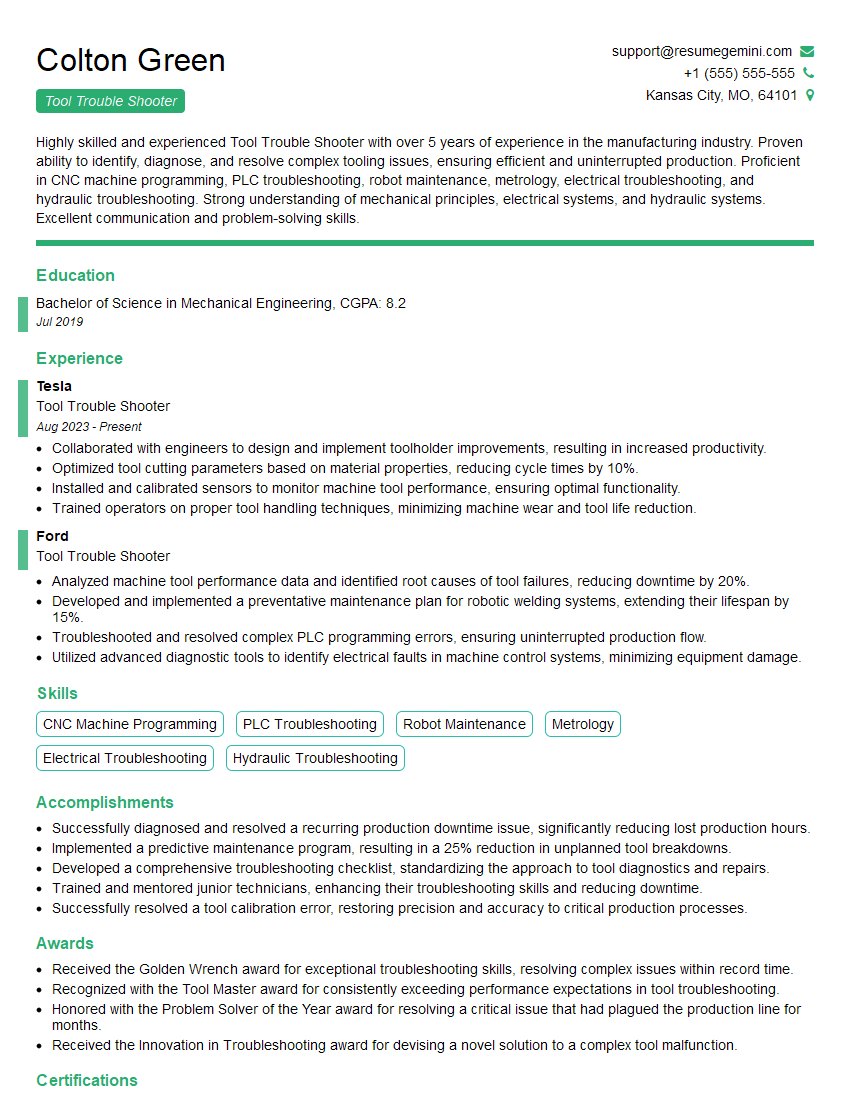

Colton Green

Tool Trouble Shooter

Summary

Highly skilled and experienced Tool Trouble Shooter with over 5 years of experience in the manufacturing industry. Proven ability to identify, diagnose, and resolve complex tooling issues, ensuring efficient and uninterrupted production. Proficient in CNC machine programming, PLC troubleshooting, robot maintenance, metrology, electrical troubleshooting, and hydraulic troubleshooting. Strong understanding of mechanical principles, electrical systems, and hydraulic systems. Excellent communication and problem-solving skills.

Education

Bachelor of Science in Mechanical Engineering

July 2019

Skills

- CNC Machine Programming

- PLC Troubleshooting

- Robot Maintenance

- Metrology

- Electrical Troubleshooting

- Hydraulic Troubleshooting

Work Experience

Tool Trouble Shooter

- Collaborated with engineers to design and implement toolholder improvements, resulting in increased productivity.

- Optimized tool cutting parameters based on material properties, reducing cycle times by 10%.

- Installed and calibrated sensors to monitor machine tool performance, ensuring optimal functionality.

- Trained operators on proper tool handling techniques, minimizing machine wear and tool life reduction.

Tool Trouble Shooter

- Analyzed machine tool performance data and identified root causes of tool failures, reducing downtime by 20%.

- Developed and implemented a preventative maintenance plan for robotic welding systems, extending their lifespan by 15%.

- Troubleshooted and resolved complex PLC programming errors, ensuring uninterrupted production flow.

- Utilized advanced diagnostic tools to identify electrical faults in machine control systems, minimizing equipment damage.

Accomplishments

- Successfully diagnosed and resolved a recurring production downtime issue, significantly reducing lost production hours.

- Implemented a predictive maintenance program, resulting in a 25% reduction in unplanned tool breakdowns.

- Developed a comprehensive troubleshooting checklist, standardizing the approach to tool diagnostics and repairs.

- Trained and mentored junior technicians, enhancing their troubleshooting skills and reducing downtime.

- Successfully resolved a tool calibration error, restoring precision and accuracy to critical production processes.

Awards

- Received the Golden Wrench award for exceptional troubleshooting skills, resolving complex issues within record time.

- Recognized with the Tool Master award for consistently exceeding performance expectations in tool troubleshooting.

- Honored with the Problem Solver of the Year award for resolving a critical issue that had plagued the production line for months.

- Received the Innovation in Troubleshooting award for devising a novel solution to a complex tool malfunction.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Tooling Technician (CTT)

- Certified Mold Maker (CMM)

- Certified Die Maker (CDM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Trouble Shooter

- Highlight your specific skills and experience in CNC machine programming, PLC troubleshooting, and robot maintenance.

- Quantify your accomplishments with specific metrics, such as the number of tooling issues resolved or the percentage of downtime reduced.

- Showcase your understanding of mechanical principles, electrical systems, and hydraulic systems.

- Emphasize your problem-solving abilities and your ability to work independently and as part of a team.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Tool Trouble Shooter Resume

- Troubleshoot and repair tooling issues on CNC machines, PLCs, robots, and other manufacturing equipment.

- Analyze tooling performance and recommend improvements to optimize production efficiency.

- Develop and implement preventative maintenance plans to minimize downtime and improve equipment longevity.

- Train and supervise junior technicians on tooling maintenance and troubleshooting procedures.

- Collaborate with engineers and production staff to identify and resolve complex tooling problems.

- Stay abreast of the latest tooling technologies and best practices through continuous training and development.

- Maintain a clean and organized work area, ensuring a safe and efficient work environment.

Frequently Asked Questions (FAQ’s) For Tool Trouble Shooter

What are the key skills required to be a successful Tool Trouble Shooter?

The key skills required to be a successful Tool Trouble Shooter include CNC machine programming, PLC troubleshooting, robot maintenance, metrology, electrical troubleshooting, and hydraulic troubleshooting.

What are the typical responsibilities of a Tool Trouble Shooter?

The typical responsibilities of a Tool Trouble Shooter include troubleshooting and repairing tooling issues on CNC machines, PLCs, robots, and other manufacturing equipment, analyzing tooling performance and recommending improvements to optimize production efficiency, and developing and implementing preventative maintenance plans to minimize downtime and improve equipment longevity.

What are the qualifications required to become a Tool Trouble Shooter?

The qualifications required to become a Tool Trouble Shooter typically include a Bachelor of Science in Mechanical Engineering or a related field, as well as several years of experience in the manufacturing industry.

What is the job outlook for Tool Trouble Shooters?

The job outlook for Tool Trouble Shooters is expected to be good over the next few years, as there is a growing demand for skilled technicians who can maintain and repair complex manufacturing equipment.

What is the average salary for a Tool Trouble Shooter?

The average salary for a Tool Trouble Shooter is around $60,000 per year.

What are the career advancement opportunities for Tool Trouble Shooters?

The career advancement opportunities for Tool Trouble Shooters include promotions to positions such as Tooling Engineer, Manufacturing Supervisor, or Plant Manager.