Are you a seasoned Tool Worker seeking a new career path? Discover our professionally built Tool Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

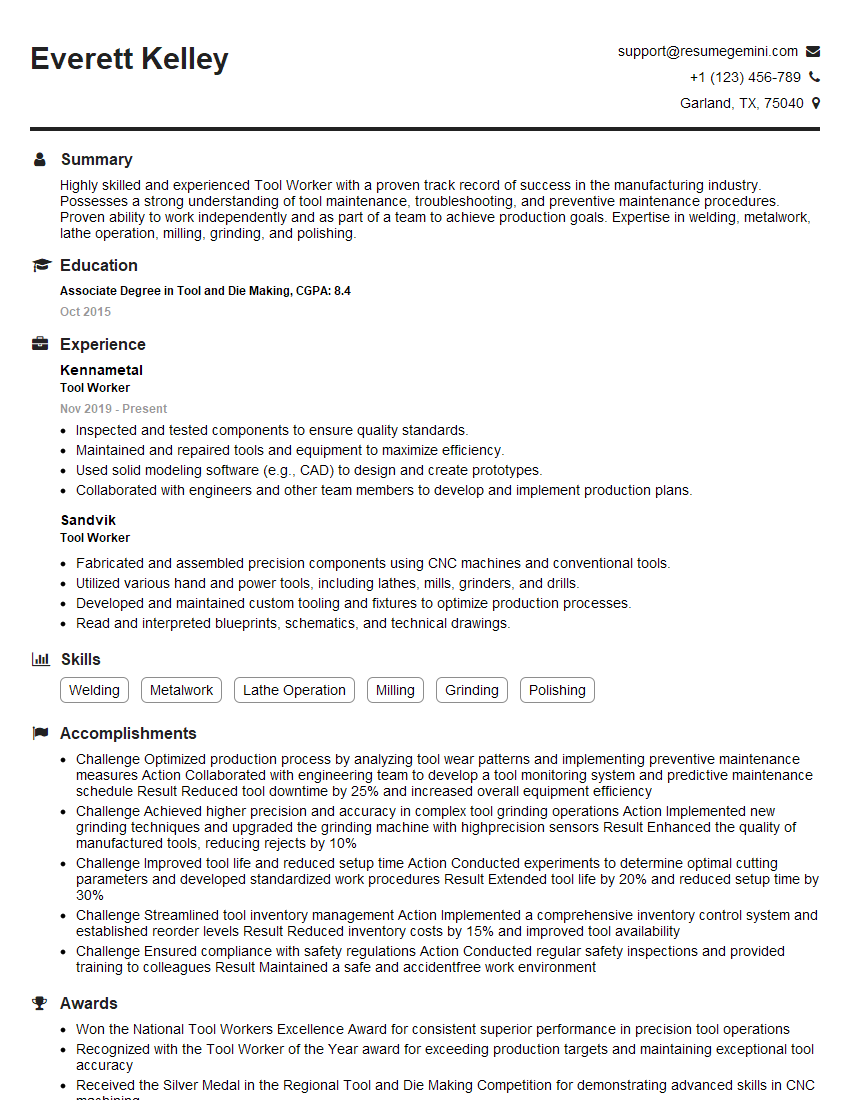

Everett Kelley

Tool Worker

Summary

Highly skilled and experienced Tool Worker with a proven track record of success in the manufacturing industry. Possesses a strong understanding of tool maintenance, troubleshooting, and preventive maintenance procedures. Proven ability to work independently and as part of a team to achieve production goals. Expertise in welding, metalwork, lathe operation, milling, grinding, and polishing.

Education

Associate Degree in Tool and Die Making

October 2015

Skills

- Welding

- Metalwork

- Lathe Operation

- Milling

- Grinding

- Polishing

Work Experience

Tool Worker

- Inspected and tested components to ensure quality standards.

- Maintained and repaired tools and equipment to maximize efficiency.

- Used solid modeling software (e.g., CAD) to design and create prototypes.

- Collaborated with engineers and other team members to develop and implement production plans.

Tool Worker

- Fabricated and assembled precision components using CNC machines and conventional tools.

- Utilized various hand and power tools, including lathes, mills, grinders, and drills.

- Developed and maintained custom tooling and fixtures to optimize production processes.

- Read and interpreted blueprints, schematics, and technical drawings.

Accomplishments

- Challenge Optimized production process by analyzing tool wear patterns and implementing preventive maintenance measures Action Collaborated with engineering team to develop a tool monitoring system and predictive maintenance schedule Result Reduced tool downtime by 25% and increased overall equipment efficiency

- Challenge Achieved higher precision and accuracy in complex tool grinding operations Action Implemented new grinding techniques and upgraded the grinding machine with highprecision sensors Result Enhanced the quality of manufactured tools, reducing rejects by 10%

- Challenge Improved tool life and reduced setup time Action Conducted experiments to determine optimal cutting parameters and developed standardized work procedures Result Extended tool life by 20% and reduced setup time by 30%

- Challenge Streamlined tool inventory management Action Implemented a comprehensive inventory control system and established reorder levels Result Reduced inventory costs by 15% and improved tool availability

- Challenge Ensured compliance with safety regulations Action Conducted regular safety inspections and provided training to colleagues Result Maintained a safe and accidentfree work environment

Awards

- Won the National Tool Workers Excellence Award for consistent superior performance in precision tool operations

- Recognized with the Tool Worker of the Year award for exceeding production targets and maintaining exceptional tool accuracy

- Received the Silver Medal in the Regional Tool and Die Making Competition for demonstrating advanced skills in CNC machining

- Received the Employee Excellence Award for dedication, hard work, and contributions to the team

Certificates

- OSHA 10Hour Safety Certification

- ASME B16.5 Flange Standards Certification

- AWS Certified Welder (CWI/CWE/CWA)

- ISO 90012015 Quality Management System Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Worker

- Highlight your technical skills and experience in tool maintenance, troubleshooting, and preventive maintenance.

- Showcase your ability to work independently and as part of a team, emphasizing your communication and interpersonal skills.

- Quantify your accomplishments using specific metrics to demonstrate your impact on production efficiency and cost reduction.

- Include relevant keywords throughout your resume to increase its visibility to potential employers.

Essential Experience Highlights for a Strong Tool Worker Resume

- Collaborate with engineering and maintenance teams to develop tool maintenance schedules and preventive maintenance strategies.

- Conduct regular inspections of tools and equipment to identify potential issues and implement corrective actions.

- Troubleshoot and repair tools and equipment to ensure optimal performance.

- Monitor tool wear patterns and implement preventive maintenance measures to extend tool life and reduce downtime.

- Maintain a safe and clean work environment adhering to all safety regulations.

- Participate in continuous improvement initiatives to optimize production processes and enhance efficiency.

- Provide technical guidance and training to colleagues on proper tool handling and maintenance procedures.

Frequently Asked Questions (FAQ’s) For Tool Worker

What are the primary responsibilities of a Tool Worker?

Tool Workers are responsible for maintaining, repairing, and troubleshooting tools and equipment used in manufacturing processes. They also implement preventive maintenance measures to extend tool life and reduce downtime, ensuring optimal production efficiency and safety.

What skills are required to be a successful Tool Worker?

Successful Tool Workers possess strong technical skills in tool maintenance, troubleshooting, and preventive maintenance. They are also proficient in welding, metalwork, lathe operation, milling, grinding, and polishing. Additionally, they have a strong understanding of safety regulations and are able to work independently and as part of a team.

What industries employ Tool Workers?

Tool Workers are employed in a wide range of industries, including automotive, aerospace, manufacturing, construction, and energy. They play a crucial role in maintaining and repairing machinery, equipment, and tools used in these industries.

What is the job outlook for Tool Workers?

The job outlook for Tool Workers is expected to be positive in the coming years. As manufacturing and industrial sectors continue to grow, the demand for skilled Tool Workers will increase.

What are the earning prospects for Tool Workers?

Tool Workers can earn competitive salaries, typically based on their experience, skills, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Tool Workers was $53,320 in May 2022.

What are the advancement opportunities for Tool Workers?

Tool Workers with experience and a strong track record can advance to supervisory roles, such as Tool Room Supervisor or Maintenance Manager. They can also pursue further education and training to specialize in areas such as CNC programming or industrial automation.

What are the challenges faced by Tool Workers?

Tool Workers may face challenges such as working in fast-paced environments, handling heavy equipment, and adhering to strict safety regulations. They may also need to troubleshoot complex technical issues and work under pressure to meet deadlines.

What are the safety precautions that Tool Workers must observe?

Tool Workers must adhere to all safety regulations and guidelines to protect themselves and others. This includes wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of potential hazards in the work environment.