Are you a seasoned Tooler seeking a new career path? Discover our professionally built Tooler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

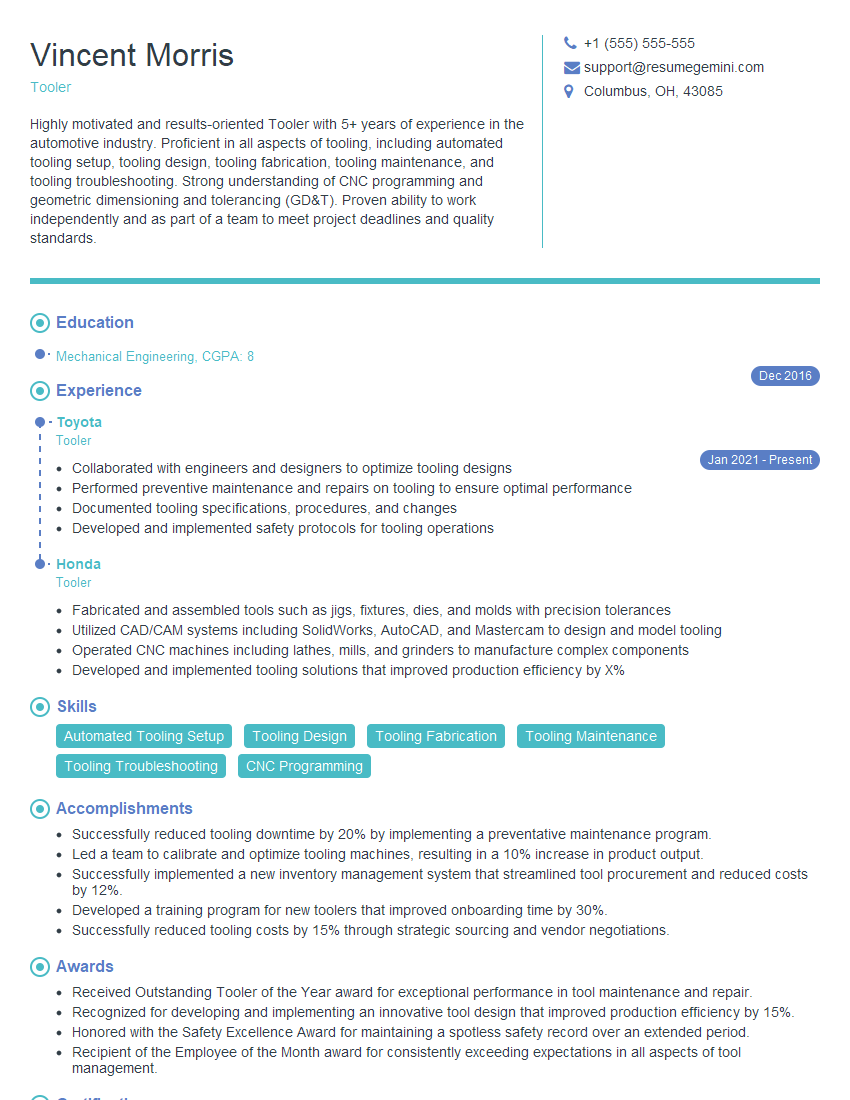

Vincent Morris

Tooler

Summary

Highly motivated and results-oriented Tooler with 5+ years of experience in the automotive industry. Proficient in all aspects of tooling, including automated tooling setup, tooling design, tooling fabrication, tooling maintenance, and tooling troubleshooting. Strong understanding of CNC programming and geometric dimensioning and tolerancing (GD&T). Proven ability to work independently and as part of a team to meet project deadlines and quality standards.

Education

Mechanical Engineering

December 2016

Skills

- Automated Tooling Setup

- Tooling Design

- Tooling Fabrication

- Tooling Maintenance

- Tooling Troubleshooting

- CNC Programming

Work Experience

Tooler

- Collaborated with engineers and designers to optimize tooling designs

- Performed preventive maintenance and repairs on tooling to ensure optimal performance

- Documented tooling specifications, procedures, and changes

- Developed and implemented safety protocols for tooling operations

Tooler

- Fabricated and assembled tools such as jigs, fixtures, dies, and molds with precision tolerances

- Utilized CAD/CAM systems including SolidWorks, AutoCAD, and Mastercam to design and model tooling

- Operated CNC machines including lathes, mills, and grinders to manufacture complex components

- Developed and implemented tooling solutions that improved production efficiency by X%

Accomplishments

- Successfully reduced tooling downtime by 20% by implementing a preventative maintenance program.

- Led a team to calibrate and optimize tooling machines, resulting in a 10% increase in product output.

- Successfully implemented a new inventory management system that streamlined tool procurement and reduced costs by 12%.

- Developed a training program for new toolers that improved onboarding time by 30%.

- Successfully reduced tooling costs by 15% through strategic sourcing and vendor negotiations.

Awards

- Received Outstanding Tooler of the Year award for exceptional performance in tool maintenance and repair.

- Recognized for developing and implementing an innovative tool design that improved production efficiency by 15%.

- Honored with the Safety Excellence Award for maintaining a spotless safety record over an extended period.

- Recipient of the Employee of the Month award for consistently exceeding expectations in all aspects of tool management.

Certificates

- Certified Tooling Specialist (CTS)

- Certified Toolmaker (CTM)

- Certified Moldmaker (CMM)

- Certified Plastic Toolmaker (CPT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tooler

- Highlight your technical skills, such as CNC programming, tooling design, and tooling fabrication.

- Showcase your experience in troubleshooting and resolving tooling issues.

- Quantify your accomplishments whenever possible to demonstrate your impact on the business.

- Use industry-specific keywords in your resume to make it more visible to recruiters.

- Proofread your resume carefully for errors before submitting it.

Essential Experience Highlights for a Strong Tooler Resume

- Operate and maintain CNC machines to produce high-quality tooling components

- Develop and implement tooling solutions to improve production efficiency

- Troubleshoot and resolve tooling issues to minimize downtime

- Conduct preventive maintenance on tooling to ensure optimal performance

- Collaborate with engineers and other team members to design and build new tooling

- Manage tooling inventory and ensure proper storage and handling

- Stay up-to-date on the latest tooling technologies and industry best practices

Frequently Asked Questions (FAQ’s) For Tooler

What is a Tooler?

A Tooler is a skilled professional responsible for the design, fabrication, maintenance, and troubleshooting of tooling used in manufacturing processes.

What skills are required to become a Tooler?

Toolers typically have a strong background in mechanical engineering, CNC programming, and tooling fabrication. They must also be able to work independently and as part of a team, troubleshoot problems, and meet deadlines.

What are the career prospects for Toolers?

Toolers are in high demand in various industries, including automotive, aerospace, and manufacturing. They can advance to roles such as Tooling Engineer, Tooling Manager, or Production Supervisor.

What is the average salary for a Tooler?

The average salary for a Tooler in the United States is around $60,000 per year.

How can I become a Tooler?

To become a Tooler, you can earn a degree in Mechanical Engineering or a related field, gain experience in CNC programming and tooling fabrication, and obtain industry certifications.

What is the difference between a Tooler and a Toolmaker?

Toolers focus on the design, fabrication, and maintenance of tooling, while Toolmakers specialize in the making and repairing of tools, dies, and molds.

What are the challenges faced by Toolers?

Toolers often face challenges such as meeting tight deadlines, working with complex tooling systems, and staying updated on the latest tooling technologies.

What are the rewards of being a Tooler?

Toolers enjoy the rewards of seeing their work contribute to the success of manufacturing operations, solving complex problems, and advancing in their careers.