Are you a seasoned Tooling Engineering Tech seeking a new career path? Discover our professionally built Tooling Engineering Tech Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

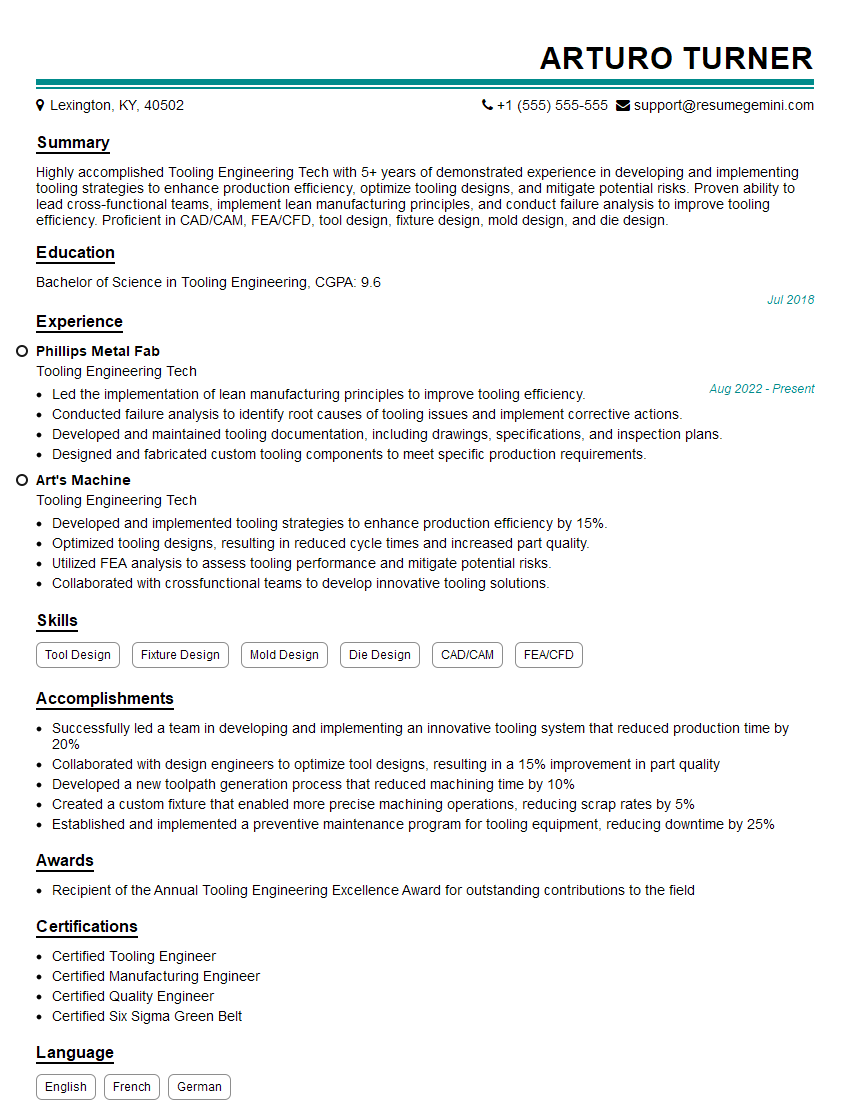

Arturo Turner

Tooling Engineering Tech

Summary

Highly accomplished Tooling Engineering Tech with 5+ years of demonstrated experience in developing and implementing tooling strategies to enhance production efficiency, optimize tooling designs, and mitigate potential risks. Proven ability to lead cross-functional teams, implement lean manufacturing principles, and conduct failure analysis to improve tooling efficiency. Proficient in CAD/CAM, FEA/CFD, tool design, fixture design, mold design, and die design.

Education

Bachelor of Science in Tooling Engineering

July 2018

Skills

- Tool Design

- Fixture Design

- Mold Design

- Die Design

- CAD/CAM

- FEA/CFD

Work Experience

Tooling Engineering Tech

- Led the implementation of lean manufacturing principles to improve tooling efficiency.

- Conducted failure analysis to identify root causes of tooling issues and implement corrective actions.

- Developed and maintained tooling documentation, including drawings, specifications, and inspection plans.

- Designed and fabricated custom tooling components to meet specific production requirements.

Tooling Engineering Tech

- Developed and implemented tooling strategies to enhance production efficiency by 15%.

- Optimized tooling designs, resulting in reduced cycle times and increased part quality.

- Utilized FEA analysis to assess tooling performance and mitigate potential risks.

- Collaborated with crossfunctional teams to develop innovative tooling solutions.

Accomplishments

- Successfully led a team in developing and implementing an innovative tooling system that reduced production time by 20%

- Collaborated with design engineers to optimize tool designs, resulting in a 15% improvement in part quality

- Developed a new toolpath generation process that reduced machining time by 10%

- Created a custom fixture that enabled more precise machining operations, reducing scrap rates by 5%

- Established and implemented a preventive maintenance program for tooling equipment, reducing downtime by 25%

Awards

- Recipient of the Annual Tooling Engineering Excellence Award for outstanding contributions to the field

Certificates

- Certified Tooling Engineer

- Certified Manufacturing Engineer

- Certified Quality Engineer

- Certified Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tooling Engineering Tech

- Highlight your expertise in CAD/CAM, FEA/CFD, and other relevant software.

- Quantify your accomplishments with specific metrics and data whenever possible.

- Showcase your ability to work in a team environment and collaborate with cross-functional groups.

- Review job descriptions carefully and tailor your resume to match the specific requirements of each position you apply for.

Essential Experience Highlights for a Strong Tooling Engineering Tech Resume

- Developed and implemented tooling strategies to enhance production efficiency by 15%.

- Optimized tooling designs, resulting in reduced cycle times and increased part quality.

- Utilized FEA analysis to assess tooling performance and mitigate potential risks.

- Collaborated with cross-functional teams to develop innovative tooling solutions.

- Led the implementation of lean manufacturing principles to improve tooling efficiency.

- Conducted failure analysis to identify root causes of tooling issues and implement corrective actions.

- Developed and maintained tooling documentation, including drawings, specifications, and inspection plans.

Frequently Asked Questions (FAQ’s) For Tooling Engineering Tech

What are the key responsibilities of a Tooling Engineering Tech?

Tooling Engineering Techs are responsible for developing and implementing tooling strategies to improve production efficiency, optimize tooling designs, conduct failure analysis, and collaborate with cross-functional teams to develop innovative tooling solutions.

What are the educational requirements for a Tooling Engineering Tech?

A Bachelor of Science in Tooling Engineering or a related field is typically required.

What are the career prospects for a Tooling Engineering Tech?

Tooling Engineering Techs can advance to positions such as Tooling Engineer, Manufacturing Engineer, or Production Manager.

What are the key skills for a Tooling Engineering Tech?

Key skills for a Tooling Engineering Tech include CAD/CAM, FEA/CFD, tool design, fixture design, mold design, die design, and project management.

What is the work environment of a Tooling Engineering Tech?

Tooling Engineering Techs typically work in a manufacturing environment, collaborating with engineers, technicians, and production staff.

What are the salary expectations for a Tooling Engineering Tech?

Salary expectations for a Tooling Engineering Tech can vary depending on experience, location, and company size. According to Salary.com, the average salary for a Tooling Engineering Tech in the United States is $75,000.

What are the benefits of working as a Tooling Engineering Tech?

Benefits of working as a Tooling Engineering Tech include job security, competitive salary, and the opportunity to make a significant contribution to the manufacturing industry.