Are you a seasoned Tooling Mechanic seeking a new career path? Discover our professionally built Tooling Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

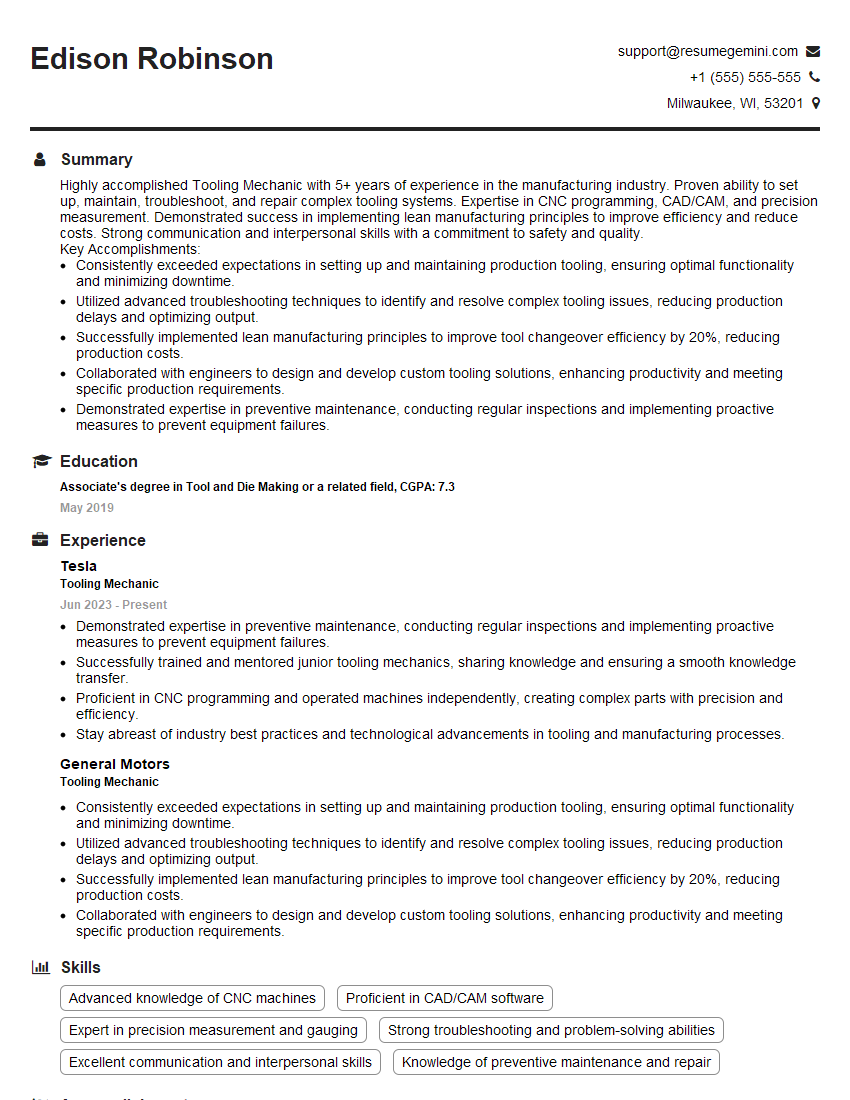

Edison Robinson

Tooling Mechanic

Summary

Highly accomplished Tooling Mechanic with 5+ years of experience in the manufacturing industry. Proven ability to set up, maintain, troubleshoot, and repair complex tooling systems. Expertise in CNC programming, CAD/CAM, and precision measurement. Demonstrated success in implementing lean manufacturing principles to improve efficiency and reduce costs. Strong communication and interpersonal skills with a commitment to safety and quality.

Key Accomplishments:

- Consistently exceeded expectations in setting up and maintaining production tooling, ensuring optimal functionality and minimizing downtime.

- Utilized advanced troubleshooting techniques to identify and resolve complex tooling issues, reducing production delays and optimizing output.

- Successfully implemented lean manufacturing principles to improve tool changeover efficiency by 20%, reducing production costs.

- Collaborated with engineers to design and develop custom tooling solutions, enhancing productivity and meeting specific production requirements.

- Demonstrated expertise in preventive maintenance, conducting regular inspections and implementing proactive measures to prevent equipment failures.

Education

Associate’s degree in Tool and Die Making or a related field

May 2019

Skills

- Advanced knowledge of CNC machines

- Proficient in CAD/CAM software

- Expert in precision measurement and gauging

- Strong troubleshooting and problem-solving abilities

- Excellent communication and interpersonal skills

- Knowledge of preventive maintenance and repair

Work Experience

Tooling Mechanic

- Demonstrated expertise in preventive maintenance, conducting regular inspections and implementing proactive measures to prevent equipment failures.

- Successfully trained and mentored junior tooling mechanics, sharing knowledge and ensuring a smooth knowledge transfer.

- Proficient in CNC programming and operated machines independently, creating complex parts with precision and efficiency.

- Stay abreast of industry best practices and technological advancements in tooling and manufacturing processes.

Tooling Mechanic

- Consistently exceeded expectations in setting up and maintaining production tooling, ensuring optimal functionality and minimizing downtime.

- Utilized advanced troubleshooting techniques to identify and resolve complex tooling issues, reducing production delays and optimizing output.

- Successfully implemented lean manufacturing principles to improve tool changeover efficiency by 20%, reducing production costs.

- Collaborated with engineers to design and develop custom tooling solutions, enhancing productivity and meeting specific production requirements.

Accomplishments

- Successfully implemented a new 5S program, reducing tooling loss by 25%

- Developed and implemented a new inspection protocol for cutting tools, improving tool life by 15%

- Collaborated with engineering to design and build a new fixture, reducing production time by 30%

- Successfully maintained and upgraded a complex CNC machine, ensuring optimal performance

- Implemented a preventative maintenance program for tooling, reducing downtime by 20%

Awards

- Certified ISO 9001 Internal Auditor

- Recognized for outstanding performance in tooling maintenance and repair

- Received a safety award for maintaining a clean and organized work area

- Certified in precision measuring and calibration techniques

Certificates

- Certified Tooling Mechanic (CTM)

- CNC Programming Certification

- Certified Quality Auditor (CQA)

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tooling Mechanic

- Highlight your experience in setting up and maintaining complex tooling systems, emphasizing your ability to minimize downtime and ensure optimal functionality.

- Showcase your troubleshooting skills by providing specific examples of how you identified and resolved complex tooling issues, leading to improved production output.

- Quantify your accomplishments whenever possible; for instance, mention the percentage improvement in tool changeover efficiency achieved through your implementation of lean manufacturing principles.

- Demonstrate your commitment to professional development by mentioning your efforts to stay up-to-date on industry best practices and technological advancements.

Essential Experience Highlights for a Strong Tooling Mechanic Resume

- Set up, maintain, troubleshoot, and repair tooling systems in accordance with specifications

- Analyze tooling performance and identify areas for improvement; implement changes to optimize efficiency and precision

- Conduct preventive maintenance inspections, lubricate moving parts, and replace worn or damaged components

- Collaborate with engineers to design and develop custom tooling solutions for specific production requirements

- Train and supervise junior tooling mechanics; provide technical guidance and ensure adherence to safety protocols

- Stay up-to-date on industry best practices and technological advancements in tooling and manufacturing processes

Frequently Asked Questions (FAQ’s) For Tooling Mechanic

What are the key skills and qualifications required for a Tooling Mechanic?

Key skills and qualifications include: Advanced knowledge of CNC machines, proficiency in CAD/CAM software, expertise in precision measurement and gauging, strong troubleshooting and problem-solving abilities, excellent communication and interpersonal skills, and knowledge of preventive maintenance and repair.

What are the primary responsibilities of a Tooling Mechanic?

Primary responsibilities include: Setting up, maintaining, troubleshooting, and repairing tooling systems; analyzing tooling performance and identifying areas for improvement; conducting preventive maintenance inspections; collaborating with engineers to design and develop custom tooling solutions; training and supervising junior tooling mechanics; and staying up-to-date on industry best practices and technological advancements.

What are the career prospects for a Tooling Mechanic?

With experience and additional training, Tooling Mechanics can advance to roles such as Tooling Supervisor, Manufacturing Engineer, or Production Manager. They may also specialize in specific areas of tooling, such as CNC programming or mold making.

What industries hire Tooling Mechanics?

Tooling Mechanics are employed in a wide range of industries, including automotive, aerospace, medical device manufacturing, and electronics. They play a crucial role in ensuring the efficient and precise operation of production machinery.

What is the work environment of a Tooling Mechanic like?

Tooling Mechanics typically work in manufacturing facilities, operating and maintaining machinery in a fast-paced, hands-on environment. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production deadlines.

What are the safety precautions that Tooling Mechanics must observe?

Tooling Mechanics must adhere to strict safety protocols, including wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of potential hazards such as moving machinery and electrical equipment.

How can I become a Tooling Mechanic?

To become a Tooling Mechanic, you typically need an associate’s degree in Tool and Die Making or a related field, or equivalent experience. Some employers may also offer apprenticeship programs that combine on-the-job training with classroom instruction.

What are the earning prospects for a Tooling Mechanic?

Earning prospects for Tooling Mechanics vary depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Tool and Die Makers in May 2021 was $56,700.