Are you a seasoned Tooling Supervisor seeking a new career path? Discover our professionally built Tooling Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

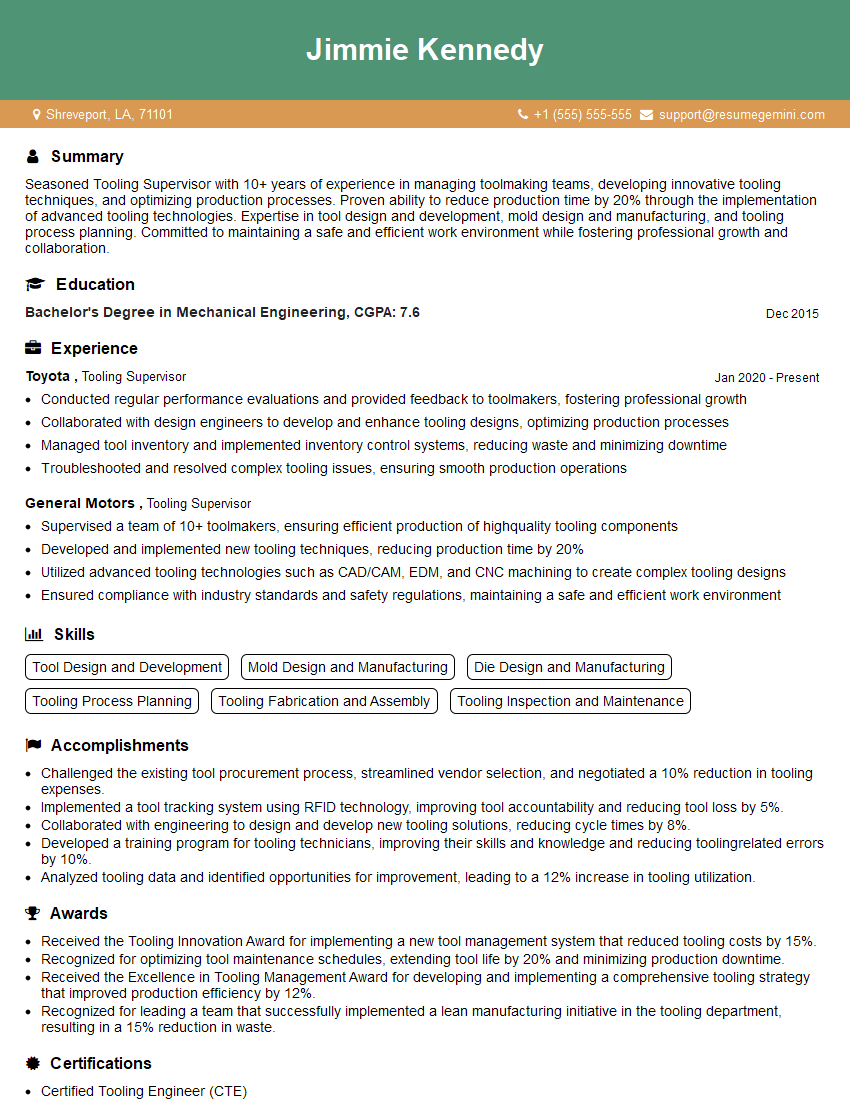

Jimmie Kennedy

Tooling Supervisor

Summary

Seasoned Tooling Supervisor with 10+ years of experience in managing toolmaking teams, developing innovative tooling techniques, and optimizing production processes. Proven ability to reduce production time by 20% through the implementation of advanced tooling technologies. Expertise in tool design and development, mold design and manufacturing, and tooling process planning. Committed to maintaining a safe and efficient work environment while fostering professional growth and collaboration.

Education

Bachelor’s Degree in Mechanical Engineering

December 2015

Skills

- Tool Design and Development

- Mold Design and Manufacturing

- Die Design and Manufacturing

- Tooling Process Planning

- Tooling Fabrication and Assembly

- Tooling Inspection and Maintenance

Work Experience

Tooling Supervisor

- Conducted regular performance evaluations and provided feedback to toolmakers, fostering professional growth

- Collaborated with design engineers to develop and enhance tooling designs, optimizing production processes

- Managed tool inventory and implemented inventory control systems, reducing waste and minimizing downtime

- Troubleshooted and resolved complex tooling issues, ensuring smooth production operations

Tooling Supervisor

- Supervised a team of 10+ toolmakers, ensuring efficient production of highquality tooling components

- Developed and implemented new tooling techniques, reducing production time by 20%

- Utilized advanced tooling technologies such as CAD/CAM, EDM, and CNC machining to create complex tooling designs

- Ensured compliance with industry standards and safety regulations, maintaining a safe and efficient work environment

Accomplishments

- Challenged the existing tool procurement process, streamlined vendor selection, and negotiated a 10% reduction in tooling expenses.

- Implemented a tool tracking system using RFID technology, improving tool accountability and reducing tool loss by 5%.

- Collaborated with engineering to design and develop new tooling solutions, reducing cycle times by 8%.

- Developed a training program for tooling technicians, improving their skills and knowledge and reducing toolingrelated errors by 10%.

- Analyzed tooling data and identified opportunities for improvement, leading to a 12% increase in tooling utilization.

Awards

- Received the Tooling Innovation Award for implementing a new tool management system that reduced tooling costs by 15%.

- Recognized for optimizing tool maintenance schedules, extending tool life by 20% and minimizing production downtime.

- Received the Excellence in Tooling Management Award for developing and implementing a comprehensive tooling strategy that improved production efficiency by 12%.

- Recognized for leading a team that successfully implemented a lean manufacturing initiative in the tooling department, resulting in a 15% reduction in waste.

Certificates

- Certified Tooling Engineer (CTE)

- Certified Manufacturing Engineer (CMfgE)

- Certified Lean Six Sigma Black Belt

- CMM Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tooling Supervisor

- Quantify your accomplishments and provide specific examples of how you improved efficiency or reduced costs.

- Highlight your expertise in tool design and development, mold design and manufacturing, and tooling process planning.

- Emphasize your ability to manage and motivate a team of toolmakers, fostering a collaborative and productive work environment.

- Demonstrate your commitment to safety and compliance, showcasing your ability to maintain a safe and efficient workplace.

- Showcase your knowledge of advanced tooling technologies and your ability to stay up-to-date with industry trends.

Essential Experience Highlights for a Strong Tooling Supervisor Resume

- Supervise and lead a team of toolmakers, ensuring efficient production of high-quality tooling components.

- Develop and implement new tooling techniques to reduce production time and enhance productivity by 20%.

- Utilize advanced tooling technologies such as CAD/CAM, EDM, and CNC machining to create complex tooling designs.

- Ensure compliance with industry standards and safety regulations, fostering a safe and efficient work environment.

- Conduct regular performance evaluations and provide feedback to toolmakers, promoting professional development and growth.

- Collaborate with design engineers to improve tooling designs and optimize production processes.

- Manage tool inventory and implement inventory control systems, minimizing waste and downtime.

- Troubleshoot and resolve complex tooling issues, ensuring smooth production operations.

Frequently Asked Questions (FAQ’s) For Tooling Supervisor

What is the primary role of a Tooling Supervisor?

Tooling Supervisors are responsible for overseeing the production of tooling components, ensuring efficiency, quality, and compliance with industry standards.

What skills are essential for a Tooling Supervisor?

Essential skills include tool design and development, mold design and manufacturing, tooling process planning, fabrication and assembly, inspection and maintenance, and proficiency in advanced tooling technologies such as CAD/CAM, EDM, and CNC machining.

What are the key responsibilities of a Tooling Supervisor?

Key responsibilities include supervising and leading a team of toolmakers, developing and implementing new tooling techniques, ensuring compliance with industry standards and safety regulations, conducting performance evaluations, collaborating with design engineers, managing tool inventory, and troubleshooting and resolving tooling issues.

What industries employ Tooling Supervisors?

Tooling Supervisors are employed in various industries that require the production of tooling components, such as automotive, aerospace, manufacturing, and electronics.

What is the career path for a Tooling Supervisor?

Tooling Supervisors may advance to roles such as Tooling Manager, Production Manager, or Plant Manager.

What is the average salary for a Tooling Supervisor?

The average salary varies depending on experience, location, and industry, but generally ranges between $60,000 and $100,000 per year.

What are the educational requirements for a Tooling Supervisor?

Most Tooling Supervisors hold a Bachelor’s Degree in Mechanical Engineering or a related field, along with relevant experience in tooling.