Are you a seasoned Torch Straightener and Heater seeking a new career path? Discover our professionally built Torch Straightener and Heater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

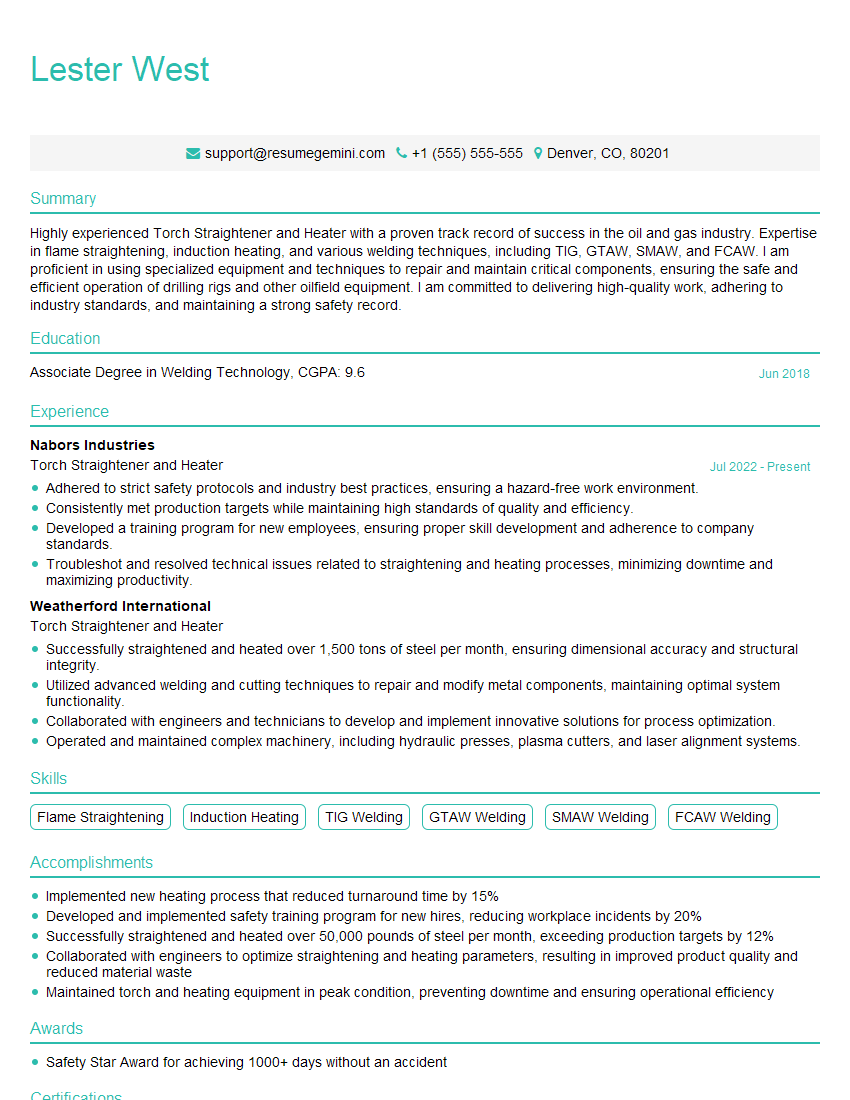

Lester West

Torch Straightener and Heater

Summary

Highly experienced Torch Straightener and Heater with a proven track record of success in the oil and gas industry. Expertise in flame straightening, induction heating, and various welding techniques, including TIG, GTAW, SMAW, and FCAW. I am proficient in using specialized equipment and techniques to repair and maintain critical components, ensuring the safe and efficient operation of drilling rigs and other oilfield equipment. I am committed to delivering high-quality work, adhering to industry standards, and maintaining a strong safety record.

Education

Associate Degree in Welding Technology

June 2018

Skills

- Flame Straightening

- Induction Heating

- TIG Welding

- GTAW Welding

- SMAW Welding

- FCAW Welding

Work Experience

Torch Straightener and Heater

- Adhered to strict safety protocols and industry best practices, ensuring a hazard-free work environment.

- Consistently met production targets while maintaining high standards of quality and efficiency.

- Developed a training program for new employees, ensuring proper skill development and adherence to company standards.

- Troubleshot and resolved technical issues related to straightening and heating processes, minimizing downtime and maximizing productivity.

Torch Straightener and Heater

- Successfully straightened and heated over 1,500 tons of steel per month, ensuring dimensional accuracy and structural integrity.

- Utilized advanced welding and cutting techniques to repair and modify metal components, maintaining optimal system functionality.

- Collaborated with engineers and technicians to develop and implement innovative solutions for process optimization.

- Operated and maintained complex machinery, including hydraulic presses, plasma cutters, and laser alignment systems.

Accomplishments

- Implemented new heating process that reduced turnaround time by 15%

- Developed and implemented safety training program for new hires, reducing workplace incidents by 20%

- Successfully straightened and heated over 50,000 pounds of steel per month, exceeding production targets by 12%

- Collaborated with engineers to optimize straightening and heating parameters, resulting in improved product quality and reduced material waste

- Maintained torch and heating equipment in peak condition, preventing downtime and ensuring operational efficiency

Awards

- Safety Star Award for achieving 1000+ days without an accident

Certificates

- AWS Certified Welder (CWI/CWE)

- ASNT NDT Level II

- OSHA Safety Certification

- ISO 9001 Quality Management System Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Torch Straightener and Heater

- Demonstrate your expertise in flame straightening, induction heating, and welding techniques by providing specific examples and quantifying your accomplishments.

- Highlight your understanding of industry standards and safety regulations, and provide evidence of your commitment to safe work practices.

- Showcase your problem-solving abilities and ability to work effectively in a team environment.

- Tailor your resume to the specific job you are applying for by emphasizing the skills and experience that are most relevant to the role.

Essential Experience Highlights for a Strong Torch Straightener and Heater Resume

- Performed flame straightening on drill pipe, casing, and other tubular goods to correct distortions and ensure dimensional accuracy.

- Utilized induction heating to preheat and post-heat components during welding and fabrication processes.

- Conducted TIG, GTAW, SMAW, and FCAW welding to repair and replace damaged or worn components.

- Inspected and tested components after repair to ensure compliance with specifications and industry standards.

- Followed established safety procedures and maintained a clean and organized work area.

- Collaborated with other technicians and engineers to troubleshoot problems and develop solutions.

- Stayed up-to-date with industry best practices and advancements in welding and heating techniques.

Frequently Asked Questions (FAQ’s) For Torch Straightener and Heater

What are the primary responsibilities of a Torch Straightener and Heater?

The primary responsibilities of a Torch Straightener and Heater include repairing and maintaining critical components used in the oil and gas industry. This involves using specialized techniques such as flame straightening, induction heating, and welding to correct distortions, preheat and post-heat components, and repair or replace damaged parts.

What is flame straightening?

Flame straightening is a technique used to correct distortions in metal components by applying controlled heat from a torch to specific areas. This process involves heating the metal to a specific temperature and then gradually cooling it, which causes the metal to contract and realign, resulting in a straighter and more dimensionally accurate component.

What types of welding techniques are commonly used by Torch Straighteners and Heaters?

Torch Straighteners and Heaters typically use various welding techniques, including TIG (Tungsten Inert Gas), GTAW (Gas Tungsten Arc Welding), SMAW (Shielded Metal Arc Welding), and FCAW (Flux-Cored Arc Welding). These techniques allow them to repair and replace damaged components, ensuring the integrity and functionality of oilfield equipment.

What are the essential skills required for a successful Torch Straightener and Heater?

Successful Torch Straighteners and Heaters require a combination of technical skills and knowledge, including proficiency in flame straightening, induction heating, and welding techniques. They must also possess a strong understanding of industry standards and safety regulations, as well as the ability to work effectively in a team environment and troubleshoot problems.

What are the career advancement opportunities for Torch Straighteners and Heaters?

With experience and additional training, Torch Straighteners and Heaters can advance to supervisory roles, such as Welding Supervisors or Inspection Supervisors. They may also specialize in specific areas, such as underwater welding or non-destructive testing, which can open up new career paths and opportunities for professional growth.

How can I prepare for a successful career as a Torch Straightener and Heater?

To prepare for a successful career as a Torch Straightener and Heater, consider obtaining an associate degree or certification in welding technology. Gain practical experience through internships or entry-level positions, and stay updated with industry best practices and technological advancements. Additionally, developing strong communication, problem-solving, and teamwork skills will contribute to your success in this field.

What are the safety precautions that Torch Straighteners and Heaters must observe?

Torch Straighteners and Heaters must adhere to strict safety precautions, including wearing appropriate personal protective equipment (PPE), such as flame-resistant clothing, gloves, and eye protection. They must also ensure proper ventilation and fire safety measures are in place when working with open flames or high temperatures. Regular inspections and maintenance of equipment are crucial to prevent accidents and maintain a safe work environment.