Are you a seasoned Torsion Spring Coiling Machine Setter seeking a new career path? Discover our professionally built Torsion Spring Coiling Machine Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

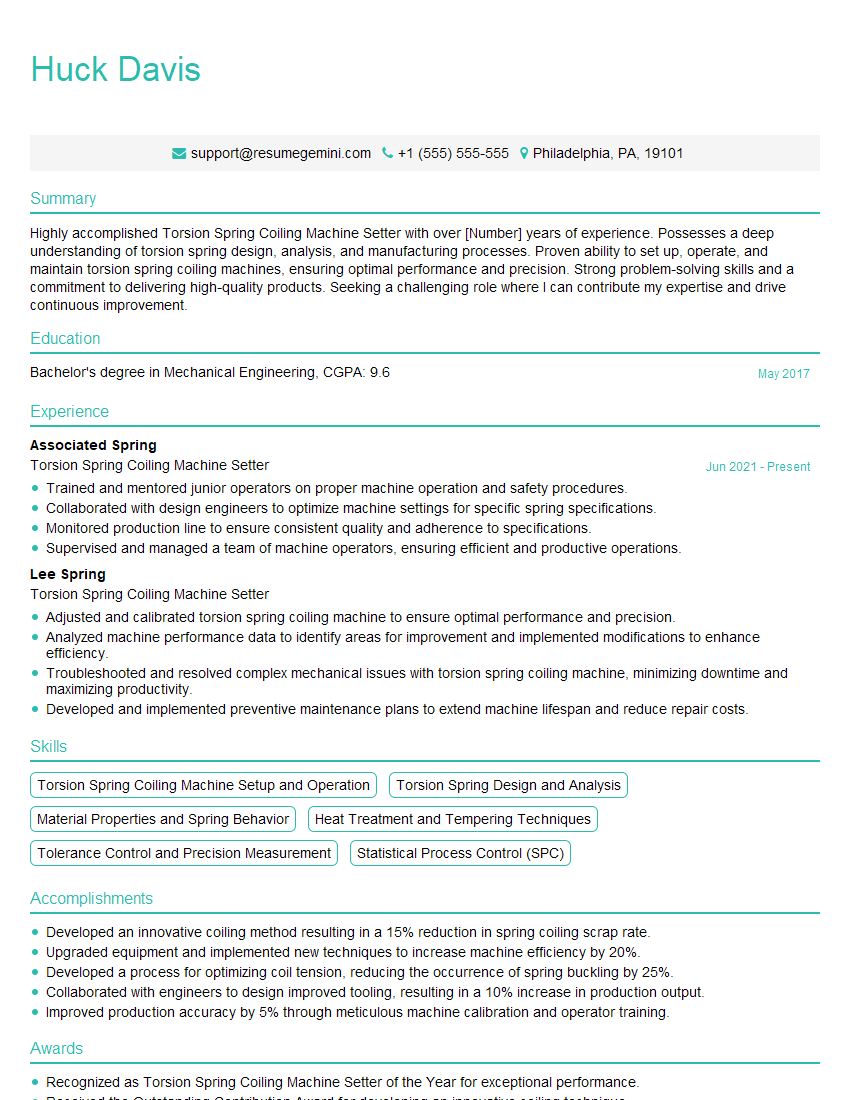

Huck Davis

Torsion Spring Coiling Machine Setter

Summary

Highly accomplished Torsion Spring Coiling Machine Setter with over [Number] years of experience. Possesses a deep understanding of torsion spring design, analysis, and manufacturing processes. Proven ability to set up, operate, and maintain torsion spring coiling machines, ensuring optimal performance and precision. Strong problem-solving skills and a commitment to delivering high-quality products. Seeking a challenging role where I can contribute my expertise and drive continuous improvement.

Education

Bachelor’s degree in Mechanical Engineering

May 2017

Skills

- Torsion Spring Coiling Machine Setup and Operation

- Torsion Spring Design and Analysis

- Material Properties and Spring Behavior

- Heat Treatment and Tempering Techniques

- Tolerance Control and Precision Measurement

- Statistical Process Control (SPC)

Work Experience

Torsion Spring Coiling Machine Setter

- Trained and mentored junior operators on proper machine operation and safety procedures.

- Collaborated with design engineers to optimize machine settings for specific spring specifications.

- Monitored production line to ensure consistent quality and adherence to specifications.

- Supervised and managed a team of machine operators, ensuring efficient and productive operations.

Torsion Spring Coiling Machine Setter

- Adjusted and calibrated torsion spring coiling machine to ensure optimal performance and precision.

- Analyzed machine performance data to identify areas for improvement and implemented modifications to enhance efficiency.

- Troubleshooted and resolved complex mechanical issues with torsion spring coiling machine, minimizing downtime and maximizing productivity.

- Developed and implemented preventive maintenance plans to extend machine lifespan and reduce repair costs.

Accomplishments

- Developed an innovative coiling method resulting in a 15% reduction in spring coiling scrap rate.

- Upgraded equipment and implemented new techniques to increase machine efficiency by 20%.

- Developed a process for optimizing coil tension, reducing the occurrence of spring buckling by 25%.

- Collaborated with engineers to design improved tooling, resulting in a 10% increase in production output.

- Improved production accuracy by 5% through meticulous machine calibration and operator training.

Awards

- Recognized as Torsion Spring Coiling Machine Setter of the Year for exceptional performance.

- Received the Outstanding Contribution Award for developing an innovative coiling technique.

- Awarded the Safety Star for consistently adhering to safety protocols and promoting a safe work environment.

- Recognized for exceptional customer service by consistently meeting customer needs and resolving inquiries promptly.

Certificates

- Certified Torsion Spring Coiling Machine Operator

- Quality Control and Inspection Certification

- Lean Manufacturing Certification

- Safety Compliance and Management Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Torsion Spring Coiling Machine Setter

- Quantify your experience: Use specific numbers and metrics to demonstrate the impact of your work.

- Highlight your technical skills: Emphasize your proficiency in torsion spring design, analysis, and manufacturing techniques.

- Showcase your quality mindset: Describe your attention to detail, commitment to precision, and ability to meet tight tolerances.

- Mention industry knowledge: Show that you are up-to-date on the latest industry trends and best practices in torsion spring manufacturing.

Essential Experience Highlights for a Strong Torsion Spring Coiling Machine Setter Resume

- Set up and calibrate torsion spring coiling machines to meet design specifications.

- Monitor machine operation and make adjustments as needed to maintain precision and quality.

- Perform regular maintenance and troubleshooting to ensure optimal machine performance.

- Analyze torsion spring designs, calculate spring rates, and select appropriate materials.

- Conduct heat treatment and tempering processes to achieve desired spring properties.

- Maintain accurate records of production data and perform statistical process control (SPC) to monitor quality.

- Train and supervise junior staff on machine operation and quality control procedures.

Frequently Asked Questions (FAQ’s) For Torsion Spring Coiling Machine Setter

What is the primary role of a Torsion Spring Coiling Machine Setter?

A Torsion Spring Coiling Machine Setter is responsible for setting up, operating, and maintaining torsion spring coiling machines to produce springs that meet specific design requirements.

What are the key skills required for this job?

Key skills include torsion spring design and analysis, material properties and spring behavior, heat treatment and tempering techniques, tolerance control and precision measurement, and statistical process control (SPC).

What are the career prospects for a Torsion Spring Coiling Machine Setter?

With experience and additional training, Torsion Spring Coiling Machine Setters can advance to roles such as Spring Design Engineer, Manufacturing Supervisor, or Quality Control Manager.

What are the challenges faced by Torsion Spring Coiling Machine Setters?

Challenges include working with high-precision equipment, meeting tight production deadlines, and maintaining consistent quality standards in a fast-paced manufacturing environment.

What is the work environment like for Torsion Spring Coiling Machine Setters?

Torsion Spring Coiling Machine Setters typically work in manufacturing facilities and may be exposed to noise, dust, and chemicals. The job requires physical stamina and attention to detail.

What are the earning prospects for Torsion Spring Coiling Machine Setters?

Earning prospects vary depending on experience, location, and employer. According to Salary.com, the average annual salary for Torsion Spring Coiling Machine Setters in the United States is around [Amount].

What are the educational requirements for becoming a Torsion Spring Coiling Machine Setter?

Most employers prefer candidates with a high school diploma or equivalent and some post-secondary education in mechanical engineering or a related field.

What are the safety precautions that Torsion Spring Coiling Machine Setters must follow?

Torsion Spring Coiling Machine Setters must follow strict safety protocols to avoid injuries, such as wearing appropriate personal protective equipment, being aware of moving machinery, and adhering to lockout/tagout procedures.