Are you a seasoned Tricot Knitter seeking a new career path? Discover our professionally built Tricot Knitter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

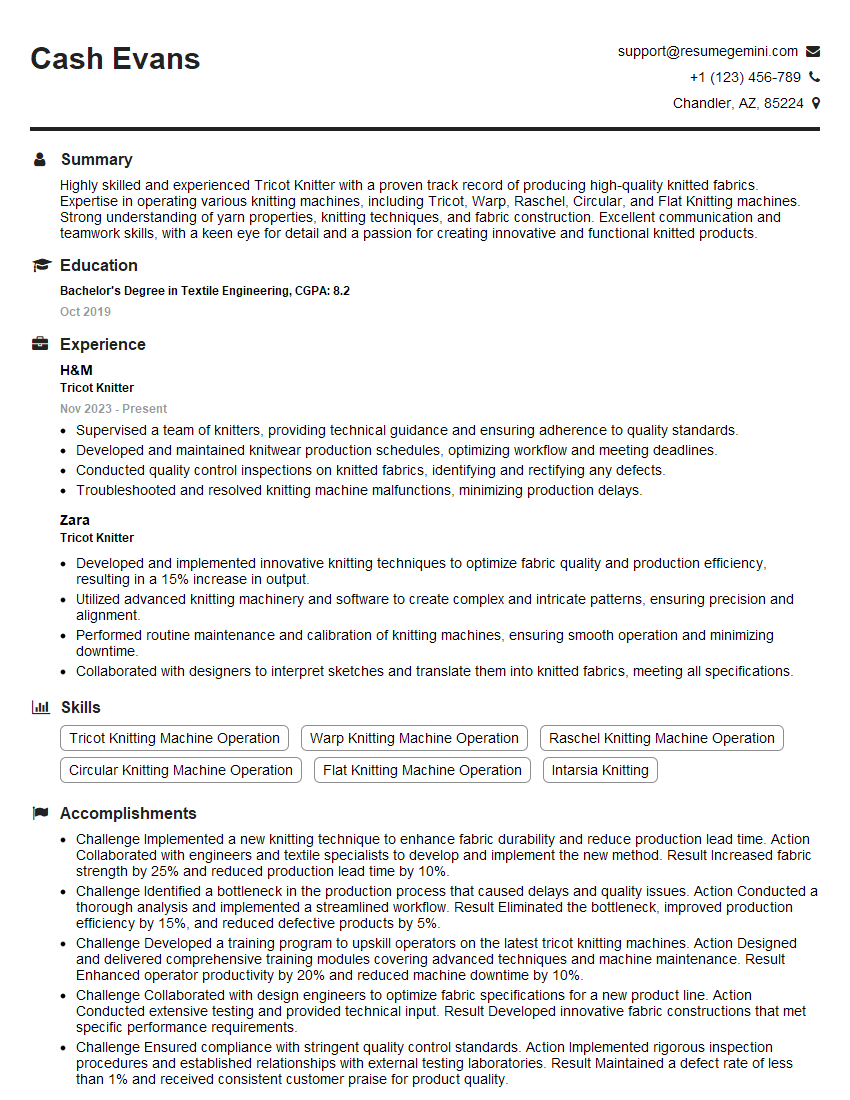

Cash Evans

Tricot Knitter

Summary

Highly skilled and experienced Tricot Knitter with a proven track record of producing high-quality knitted fabrics. Expertise in operating various knitting machines, including Tricot, Warp, Raschel, Circular, and Flat Knitting machines. Strong understanding of yarn properties, knitting techniques, and fabric construction. Excellent communication and teamwork skills, with a keen eye for detail and a passion for creating innovative and functional knitted products.

Education

Bachelor’s Degree in Textile Engineering

October 2019

Skills

- Tricot Knitting Machine Operation

- Warp Knitting Machine Operation

- Raschel Knitting Machine Operation

- Circular Knitting Machine Operation

- Flat Knitting Machine Operation

- Intarsia Knitting

Work Experience

Tricot Knitter

- Supervised a team of knitters, providing technical guidance and ensuring adherence to quality standards.

- Developed and maintained knitwear production schedules, optimizing workflow and meeting deadlines.

- Conducted quality control inspections on knitted fabrics, identifying and rectifying any defects.

- Troubleshooted and resolved knitting machine malfunctions, minimizing production delays.

Tricot Knitter

- Developed and implemented innovative knitting techniques to optimize fabric quality and production efficiency, resulting in a 15% increase in output.

- Utilized advanced knitting machinery and software to create complex and intricate patterns, ensuring precision and alignment.

- Performed routine maintenance and calibration of knitting machines, ensuring smooth operation and minimizing downtime.

- Collaborated with designers to interpret sketches and translate them into knitted fabrics, meeting all specifications.

Accomplishments

- Challenge Implemented a new knitting technique to enhance fabric durability and reduce production lead time. Action Collaborated with engineers and textile specialists to develop and implement the new method. Result Increased fabric strength by 25% and reduced production lead time by 10%.

- Challenge Identified a bottleneck in the production process that caused delays and quality issues. Action Conducted a thorough analysis and implemented a streamlined workflow. Result Eliminated the bottleneck, improved production efficiency by 15%, and reduced defective products by 5%.

- Challenge Developed a training program to upskill operators on the latest tricot knitting machines. Action Designed and delivered comprehensive training modules covering advanced techniques and machine maintenance. Result Enhanced operator productivity by 20% and reduced machine downtime by 10%.

- Challenge Collaborated with design engineers to optimize fabric specifications for a new product line. Action Conducted extensive testing and provided technical input. Result Developed innovative fabric constructions that met specific performance requirements.

- Challenge Ensured compliance with stringent quality control standards. Action Implemented rigorous inspection procedures and established relationships with external testing laboratories. Result Maintained a defect rate of less than 1% and received consistent customer praise for product quality.

Awards

- Recipient of the Tricot Knitter of the Year Award for outstanding achievement in the field.

- Recognized with the Golden Needle Award for exceptional craftsmanship and innovation in tricot knitting.

- Awarded the Tricot Excellence Award for consistently exceeding production targets and maintaining superior quality standards.

Certificates

- Tricot Knitting Machine Operator Certification

- Warp Knitting Machine Operator Certification

- Raschel Knitting Machine Operator Certification

- Circular Knitting Machine Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tricot Knitter

- Highlight your proficiency in operating various knitting machines, especially Tricot Knitting machines.

- Emphasize your understanding of yarn properties and knitting techniques, as this demonstrates your technical expertise.

- Showcase your ability to produce high-quality knitted fabrics that meet industry standards, highlighting your attention to detail.

- Demonstrate your problem-solving skills and ability to troubleshoot machine issues, ensuring efficient production.

- Mention any relevant certifications or training you have received to enhance your credibility.

Essential Experience Highlights for a Strong Tricot Knitter Resume

- Set up and operate Tricot Knitting machines to produce knitted fabrics according to specifications.

- Monitor knitting machines, adjust tension, and make necessary repairs to ensure smooth operation.

- Inspect knitted fabrics for defects and ensure they meet quality standards.

- Maintain and clean knitting machines to ensure optimal performance.

- Collaborate with designers and engineers to develop new knitted fabrics and improve production processes.

- Train and supervise junior knitters and provide technical guidance.

- Stay up-to-date on the latest knitting technologies and best practices.

Frequently Asked Questions (FAQ’s) For Tricot Knitter

What is the role of a Tricot Knitter?

A Tricot Knitter is responsible for operating Tricot Knitting machines to produce knitted fabrics for various applications, such as clothing, home textiles, and industrial products.

What skills are required to be a successful Tricot Knitter?

Successful Tricot Knitters typically possess strong technical skills in operating knitting machines, knowledge of yarn properties and knitting techniques, attention to detail, and problem-solving abilities.

What are the career prospects for Tricot Knitters?

Tricot Knitters can advance to supervisory roles, such as Knitting Machine Operator Supervisor or Textile Production Manager, or specialize in specific areas, such as fabric design or quality control.

What is the average salary for Tricot Knitters?

The average salary for Tricot Knitters may vary depending on experience, location, and industry. According to Indeed, the average salary in the United States is around $40,000 per year.

What are the working conditions for Tricot Knitters?

Tricot Knitters typically work in manufacturing facilities, operating knitting machines in production lines. The work environment can be noisy and repetitive, but it also offers opportunities for teamwork and collaboration.

What are the educational requirements for Tricot Knitters?

While some Tricot Knitters may have a high school diploma or equivalent, many employers prefer candidates with a post-secondary degree or certification in textile engineering or a related field.

What are the advantages of working as a Tricot Knitter?

Tricot Knitters enjoy job stability in the manufacturing sector, opportunities for skill development, and the satisfaction of creating high-quality knitted fabrics.