Are you a seasoned Trimming Machine Operator seeking a new career path? Discover our professionally built Trimming Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

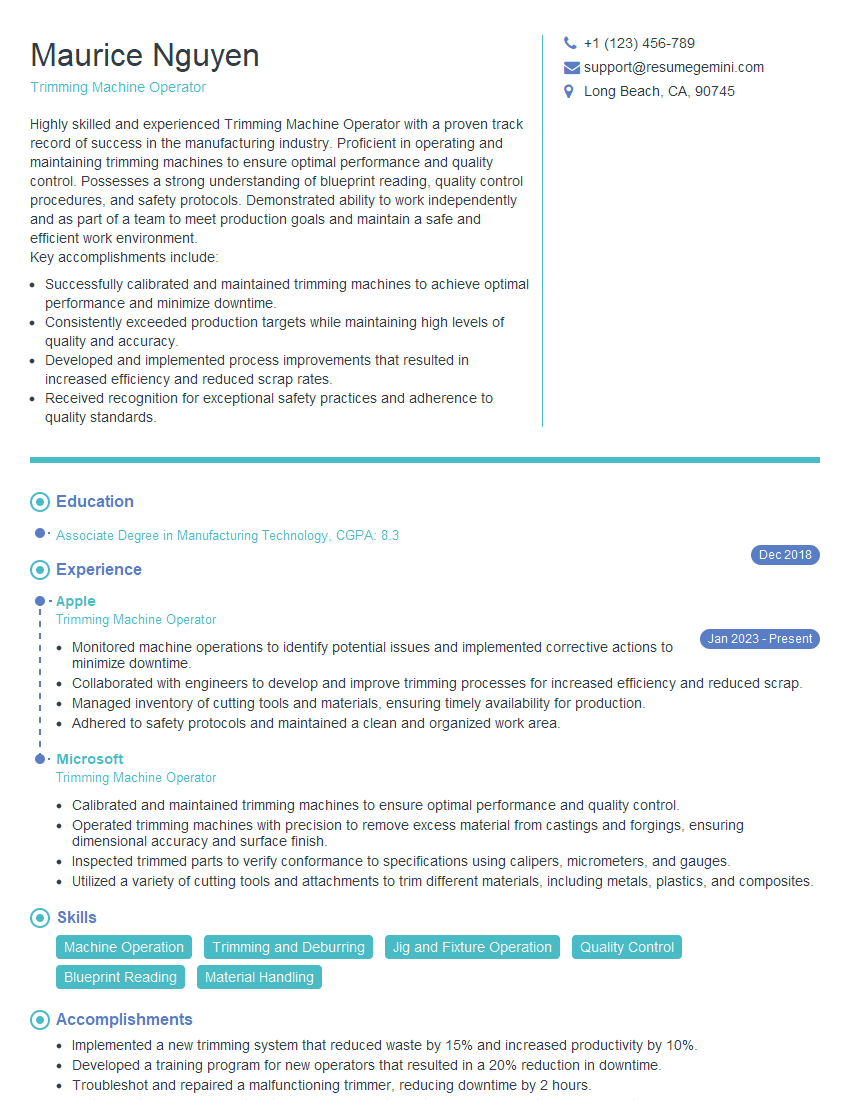

Maurice Nguyen

Trimming Machine Operator

Summary

Highly skilled and experienced Trimming Machine Operator with a proven track record of success in the manufacturing industry. Proficient in operating and maintaining trimming machines to ensure optimal performance and quality control. Possesses a strong understanding of blueprint reading, quality control procedures, and safety protocols. Demonstrated ability to work independently and as part of a team to meet production goals and maintain a safe and efficient work environment.

Key accomplishments include:

- Successfully calibrated and maintained trimming machines to achieve optimal performance and minimize downtime.

- Consistently exceeded production targets while maintaining high levels of quality and accuracy.

- Developed and implemented process improvements that resulted in increased efficiency and reduced scrap rates.

- Received recognition for exceptional safety practices and adherence to quality standards.

Education

Associate Degree in Manufacturing Technology

December 2018

Skills

- Machine Operation

- Trimming and Deburring

- Jig and Fixture Operation

- Quality Control

- Blueprint Reading

- Material Handling

Work Experience

Trimming Machine Operator

- Monitored machine operations to identify potential issues and implemented corrective actions to minimize downtime.

- Collaborated with engineers to develop and improve trimming processes for increased efficiency and reduced scrap.

- Managed inventory of cutting tools and materials, ensuring timely availability for production.

- Adhered to safety protocols and maintained a clean and organized work area.

Trimming Machine Operator

- Calibrated and maintained trimming machines to ensure optimal performance and quality control.

- Operated trimming machines with precision to remove excess material from castings and forgings, ensuring dimensional accuracy and surface finish.

- Inspected trimmed parts to verify conformance to specifications using calipers, micrometers, and gauges.

- Utilized a variety of cutting tools and attachments to trim different materials, including metals, plastics, and composites.

Accomplishments

- Implemented a new trimming system that reduced waste by 15% and increased productivity by 10%.

- Developed a training program for new operators that resulted in a 20% reduction in downtime.

- Troubleshot and repaired a malfunctioning trimmer, reducing downtime by 2 hours.

- Optimized trimming parameters to improve product quality and reduce customer complaints by 5%.

- Collaborated with engineers to develop a new trimming tool that improved precision and reduced cycle time.

Awards

- Received the Operator of the Month award for exceptional performance in trimming operations.

- Recognized by supervisors for consistent high performance and dedication to the job.

- Recognized as a top performer in trimming operations, receiving the Performance Excellence Award.

- Received the Operator of the Year award for outstanding performance in trimming operations.

Certificates

- CNC Machine Operator Certification

- Quality Control Inspector Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Trimming Machine Operator

- Highlight your experience and skills in operating and maintaining trimming machines.

- Demonstrate your understanding of quality control procedures and safety protocols.

- Quantify your accomplishments with specific metrics whenever possible.

- Showcase your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Trimming Machine Operator Resume

- Calibrated and maintained trimming machines to ensure optimal performance and quality control.

- Operated trimming machines with precision to remove excess material from castings and forgings, ensuring dimensional accuracy and surface finish.

- Inspected trimmed parts to verify conformance to specifications using calipers, micrometers, and gauges.

- Utilized a variety of cutting tools and attachments to trim different materials, including metals, plastics, and composites.

- Monitored machine operations to identify potential issues and implemented corrective actions to minimize downtime.

- Collaborated with engineers to develop and improve trimming processes for increased efficiency and reduced scrap.

- Managed inventory of cutting tools and materials, ensuring timely availability for production.

Frequently Asked Questions (FAQ’s) For Trimming Machine Operator

What are the primary responsibilities of a Trimming Machine Operator?

The primary responsibilities of a Trimming Machine Operator include calibrating and maintaining trimming machines, operating trimming machines to remove excess material from castings and forgings, inspecting trimmed parts to verify conformance to specifications, utilizing a variety of cutting tools and attachments to trim different materials, monitoring machine operations to identify potential issues and implement corrective actions, collaborating with engineers to develop and improve trimming processes, and managing inventory of cutting tools and materials.

What skills are required to be a successful Trimming Machine Operator?

Successful Trimming Machine Operators typically possess skills such as machine operation, trimming and deburring, jig and fixture operation, quality control, blueprint reading, and material handling.

What is the work environment of a Trimming Machine Operator?

Trimming Machine Operators typically work in manufacturing facilities, operating trimming machines in a production environment. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production demands.

What are the career prospects for Trimming Machine Operators?

Trimming Machine Operators with experience and a strong track record of success may advance to supervisory or management positions within the manufacturing industry.

What is the average salary of a Trimming Machine Operator?

The average salary of a Trimming Machine Operator varies depending on experience, location, and employer. According to Indeed, the average salary for a Trimming Machine Operator in the United States is around $25 per hour.