Are you a seasoned Tube Building Machine Operator seeking a new career path? Discover our professionally built Tube Building Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

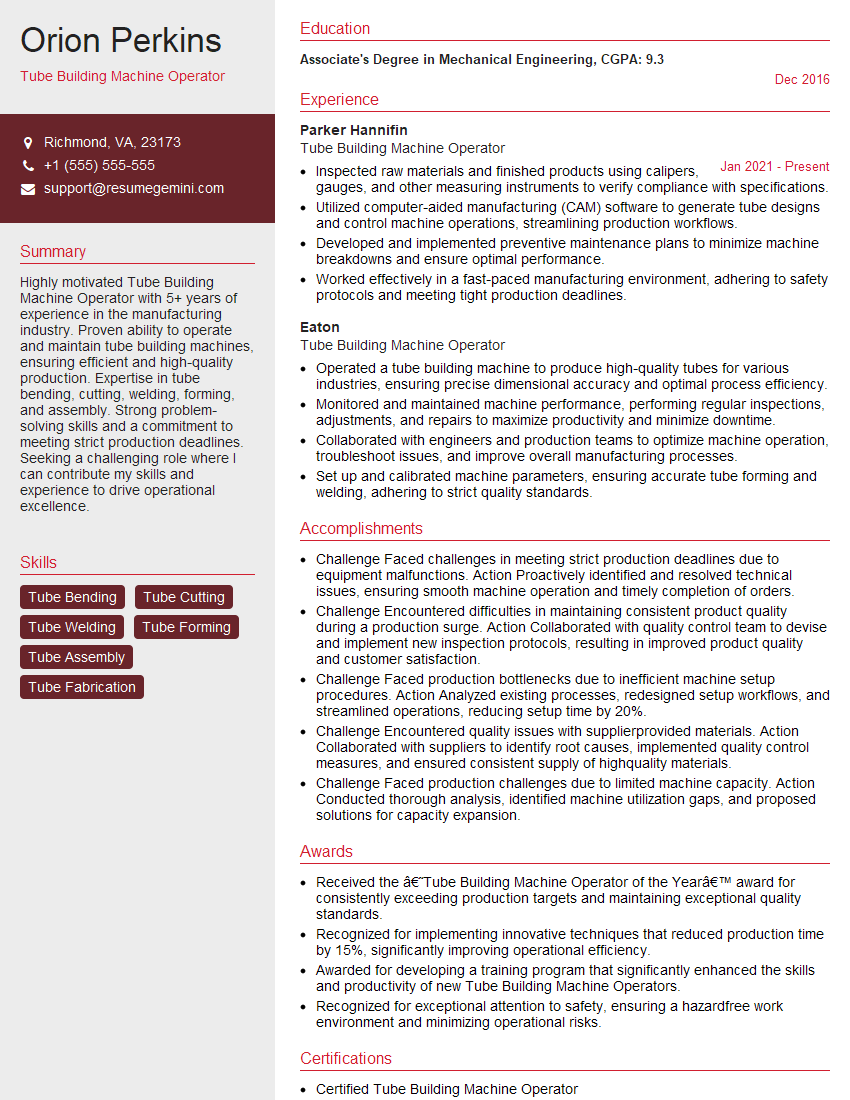

Orion Perkins

Tube Building Machine Operator

Summary

Highly motivated Tube Building Machine Operator with 5+ years of experience in the manufacturing industry. Proven ability to operate and maintain tube building machines, ensuring efficient and high-quality production. Expertise in tube bending, cutting, welding, forming, and assembly. Strong problem-solving skills and a commitment to meeting strict production deadlines. Seeking a challenging role where I can contribute my skills and experience to drive operational excellence.

Education

Associate’s Degree in Mechanical Engineering

December 2016

Skills

- Tube Bending

- Tube Cutting

- Tube Welding

- Tube Forming

- Tube Assembly

- Tube Fabrication

Work Experience

Tube Building Machine Operator

- Inspected raw materials and finished products using calipers, gauges, and other measuring instruments to verify compliance with specifications.

- Utilized computer-aided manufacturing (CAM) software to generate tube designs and control machine operations, streamlining production workflows.

- Developed and implemented preventive maintenance plans to minimize machine breakdowns and ensure optimal performance.

- Worked effectively in a fast-paced manufacturing environment, adhering to safety protocols and meeting tight production deadlines.

Tube Building Machine Operator

- Operated a tube building machine to produce high-quality tubes for various industries, ensuring precise dimensional accuracy and optimal process efficiency.

- Monitored and maintained machine performance, performing regular inspections, adjustments, and repairs to maximize productivity and minimize downtime.

- Collaborated with engineers and production teams to optimize machine operation, troubleshoot issues, and improve overall manufacturing processes.

- Set up and calibrated machine parameters, ensuring accurate tube forming and welding, adhering to strict quality standards.

Accomplishments

- Challenge Faced challenges in meeting strict production deadlines due to equipment malfunctions. Action Proactively identified and resolved technical issues, ensuring smooth machine operation and timely completion of orders.

- Challenge Encountered difficulties in maintaining consistent product quality during a production surge. Action Collaborated with quality control team to devise and implement new inspection protocols, resulting in improved product quality and customer satisfaction.

- Challenge Faced production bottlenecks due to inefficient machine setup procedures. Action Analyzed existing processes, redesigned setup workflows, and streamlined operations, reducing setup time by 20%.

- Challenge Encountered quality issues with supplierprovided materials. Action Collaborated with suppliers to identify root causes, implemented quality control measures, and ensured consistent supply of highquality materials.

- Challenge Faced production challenges due to limited machine capacity. Action Conducted thorough analysis, identified machine utilization gaps, and proposed solutions for capacity expansion.

Awards

- Received the ‘Tube Building Machine Operator of the Year’ award for consistently exceeding production targets and maintaining exceptional quality standards.

- Recognized for implementing innovative techniques that reduced production time by 15%, significantly improving operational efficiency.

- Awarded for developing a training program that significantly enhanced the skills and productivity of new Tube Building Machine Operators.

- Recognized for exceptional attention to safety, ensuring a hazardfree work environment and minimizing operational risks.

Certificates

- Certified Tube Building Machine Operator

- Certified Tube Bender

- Certified Tube Welder

- Certified Tube Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tube Building Machine Operator

- Highlight your technical skills and experience in operating and maintaining tube building machines.

- Quantify your accomplishments using specific metrics to demonstrate your impact on production.

- Showcase your problem-solving abilities by providing examples of how you have resolved machine malfunctions.

- Emphasize your commitment to safety and quality by describing your adherence to industry standards and practices.

- Tailor your resume to the specific requirements of the job you are applying for.

Essential Experience Highlights for a Strong Tube Building Machine Operator Resume

- Set up, operate, and maintain tube building machines to produce high-quality tubular products.

- Interpret blueprints, drawings, and work orders to determine production requirements.

- Inspect and measure tubes to ensure compliance with specifications and quality standards.

- Troubleshoot and resolve machine malfunctions promptly to minimize downtime.

- Collaborate with team members to optimize production processes and improve efficiency.

- Maintain a clean and safe work environment in accordance with safety regulations.

- Perform routine maintenance and repairs on tube building machines to ensure optimal performance.

Frequently Asked Questions (FAQ’s) For Tube Building Machine Operator

What is the primary responsibility of a Tube Building Machine Operator?

The primary responsibility of a Tube Building Machine Operator is to operate and maintain tube building machines to produce high-quality tubular products.

What skills are required to be a successful Tube Building Machine Operator?

Successful Tube Building Machine Operators typically have a strong understanding of tube bending, cutting, welding, forming, and assembly techniques, as well as experience in operating and maintaining tube building machines.

What are the career prospects for Tube Building Machine Operators?

Tube Building Machine Operators can advance their careers by becoming supervisors or managers in the manufacturing industry. They may also specialize in a particular area of tube fabrication, such as welding or bending.

What is the average salary for a Tube Building Machine Operator?

The average salary for a Tube Building Machine Operator in the United States is around $45,000 per year.

What are the working conditions like for Tube Building Machine Operators?

Tube Building Machine Operators typically work in manufacturing facilities and may be exposed to noise, dust, and fumes. They may also work in confined spaces or at heights.

What is the job outlook for Tube Building Machine Operators?

The job outlook for Tube Building Machine Operators is expected to be good over the next few years due to the increasing demand for tubular products in various industries.

What are the benefits of working as a Tube Building Machine Operator?

Benefits of working as a Tube Building Machine Operator include competitive salaries, opportunities for career advancement, and the satisfaction of working in a skilled trade.

What are the challenges of working as a Tube Building Machine Operator?

Challenges of working as a Tube Building Machine Operator include working in a fast-paced environment, meeting strict production deadlines, and working with heavy machinery.