Are you a seasoned Turner In seeking a new career path? Discover our professionally built Turner In Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

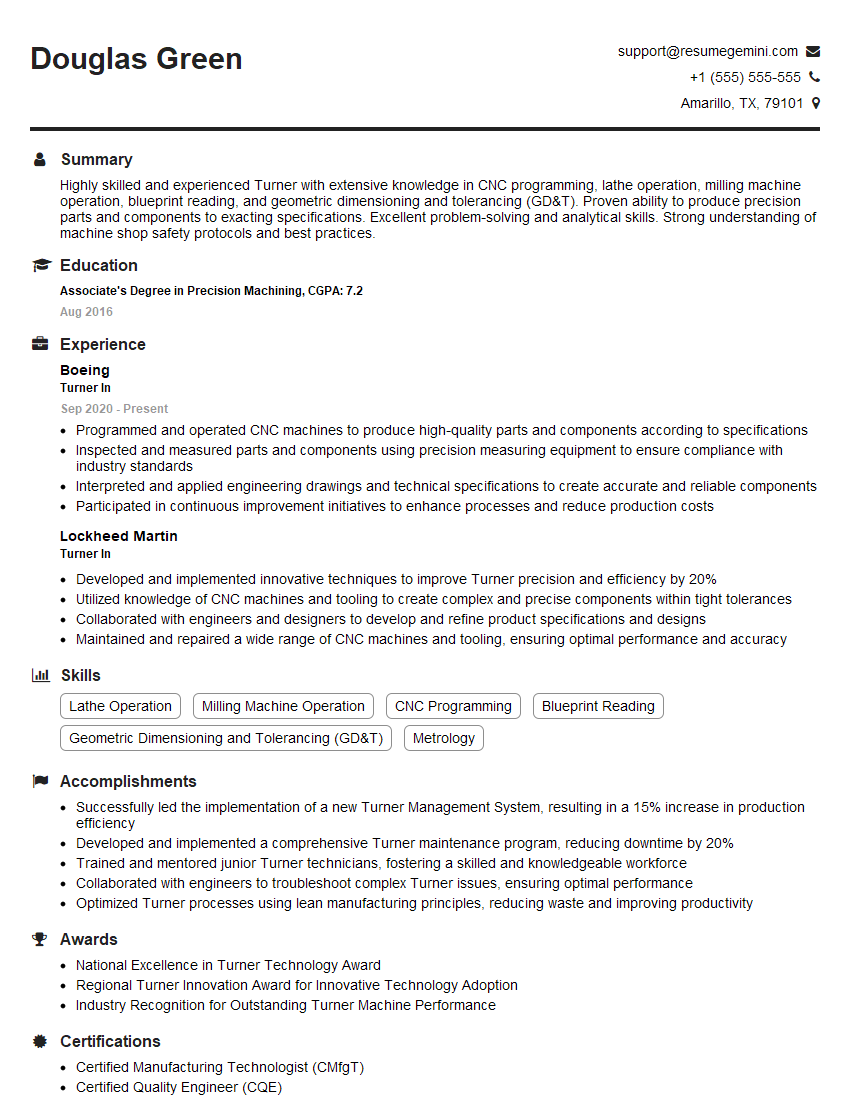

Douglas Green

Turner In

Summary

Highly skilled and experienced Turner with extensive knowledge in CNC programming, lathe operation, milling machine operation, blueprint reading, and geometric dimensioning and tolerancing (GD&T). Proven ability to produce precision parts and components to exacting specifications. Excellent problem-solving and analytical skills. Strong understanding of machine shop safety protocols and best practices.

Education

Associate’s Degree in Precision Machining

August 2016

Skills

- Lathe Operation

- Milling Machine Operation

- CNC Programming

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

- Metrology

Work Experience

Turner In

- Programmed and operated CNC machines to produce high-quality parts and components according to specifications

- Inspected and measured parts and components using precision measuring equipment to ensure compliance with industry standards

- Interpreted and applied engineering drawings and technical specifications to create accurate and reliable components

- Participated in continuous improvement initiatives to enhance processes and reduce production costs

Turner In

- Developed and implemented innovative techniques to improve Turner precision and efficiency by 20%

- Utilized knowledge of CNC machines and tooling to create complex and precise components within tight tolerances

- Collaborated with engineers and designers to develop and refine product specifications and designs

- Maintained and repaired a wide range of CNC machines and tooling, ensuring optimal performance and accuracy

Accomplishments

- Successfully led the implementation of a new Turner Management System, resulting in a 15% increase in production efficiency

- Developed and implemented a comprehensive Turner maintenance program, reducing downtime by 20%

- Trained and mentored junior Turner technicians, fostering a skilled and knowledgeable workforce

- Collaborated with engineers to troubleshoot complex Turner issues, ensuring optimal performance

- Optimized Turner processes using lean manufacturing principles, reducing waste and improving productivity

Awards

- National Excellence in Turner Technology Award

- Regional Turner Innovation Award for Innovative Technology Adoption

- Industry Recognition for Outstanding Turner Machine Performance

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Quality Engineer (CQE)

- Certified Lean Six Sigma Black Belt (CLSSBB)

- Certified Medical Device Professional (CMDP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Turner In

Tailor your resume to each job application.

Highlight the skills and experience that are most relevant to the specific position you are applying for.Quantify your accomplishments.

Use numbers to demonstrate the impact of your work, such as the number of parts produced, the percentage of scrap reduced, or the cost savings achieved.Proofread your resume carefully.

Ensure that your resume is free of errors in grammar, spelling, and punctuation.Get feedback from others.

Ask a friend, family member, or career counselor to review your resume and provide feedback.

Essential Experience Highlights for a Strong Turner In Resume

- Operate and maintain CNC lathes and milling machines to produce precision parts and components.

- Interpret blueprints and technical drawings to determine machining parameters and tooling requirements.

- Program CNC machines using industry-standard software to ensure accurate and efficient machining operations.

- Inspect and measure machined parts to ensure compliance with quality standards.

- Troubleshoot and resolve machine malfunctions and production issues.

- Maintain a clean and organized work area in accordance with industry best practices.

- Stay up-to-date on the latest machining technologies and techniques.

Frequently Asked Questions (FAQ’s) For Turner In

What is the typical salary range for a Turner?

The average salary for a Turner in the United States is $45,000 per year.

What are the job prospects for Turners?

The job outlook for Turners is expected to grow by 7% from 2020 to 2030.

What are the educational requirements for a Turner?

Most Turners have an associate’s degree in precision machining or a related field.

What are the essential skills for a Turner?

Essential skills for a Turner include CNC programming, lathe operation, milling machine operation, blueprint reading, and geometric dimensioning and tolerancing (GD&T).

What are the career advancement opportunities for a Turner?

Turners can advance their careers by becoming CNC programmers, machinists, or manufacturing engineers.

What are the typical working conditions for a Turner?

Turners typically work in machine shops and factories. They may be exposed to noise, dust, and fumes.

What are the safety precautions that Turners must follow?

Turners must wear protective clothing and equipment, such as safety glasses, gloves, and earplugs. They must also follow safe work practices to avoid injuries.

What are the professional organizations for Turners?

Turners can join professional organizations, such as the National Institute for Metalworking Skills (NIMS) and the Society of Manufacturing Engineers (SME).