Are you a seasoned Turning Lathe Tender seeking a new career path? Discover our professionally built Turning Lathe Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

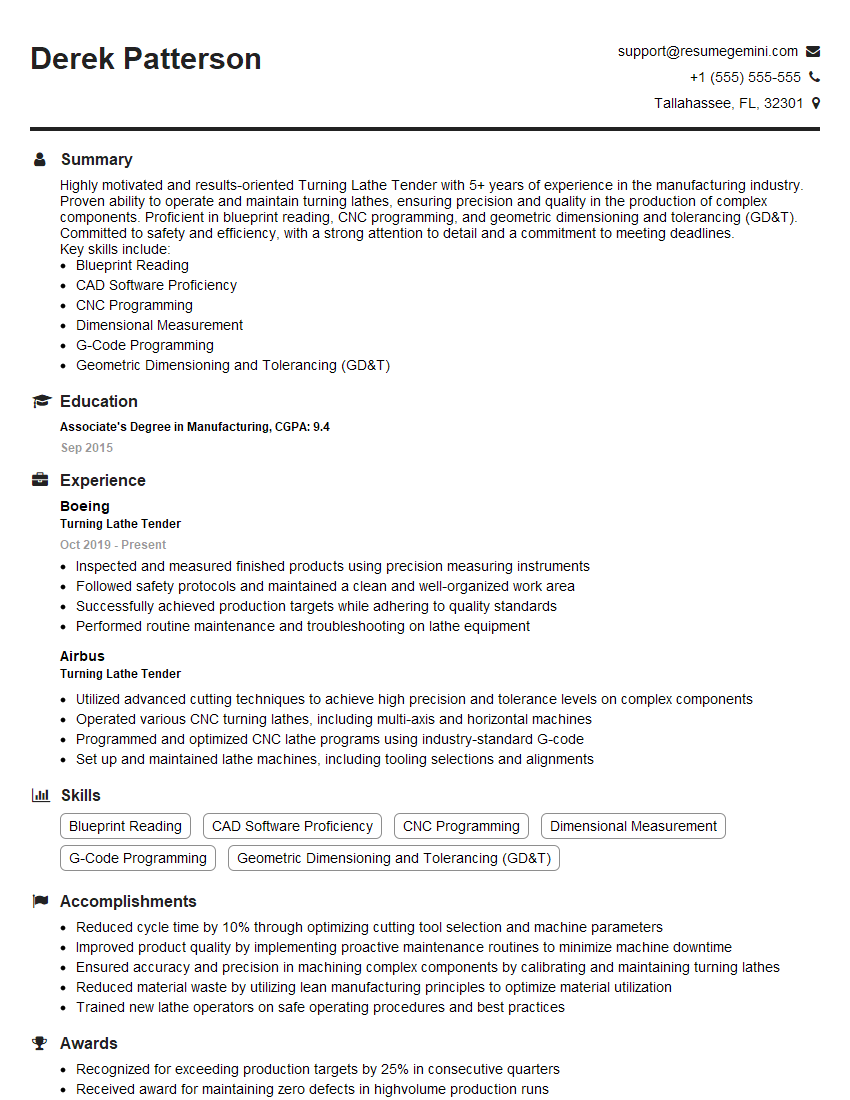

Derek Patterson

Turning Lathe Tender

Summary

Highly motivated and results-oriented Turning Lathe Tender with 5+ years of experience in the manufacturing industry. Proven ability to operate and maintain turning lathes, ensuring precision and quality in the production of complex components. Proficient in blueprint reading, CNC programming, and geometric dimensioning and tolerancing (GD&T). Committed to safety and efficiency, with a strong attention to detail and a commitment to meeting deadlines.

Key skills include:

- Blueprint Reading

- CAD Software Proficiency

- CNC Programming

- Dimensional Measurement

- G-Code Programming

- Geometric Dimensioning and Tolerancing (GD&T)

Education

Associate’s Degree in Manufacturing

September 2015

Skills

- Blueprint Reading

- CAD Software Proficiency

- CNC Programming

- Dimensional Measurement

- G-Code Programming

- Geometric Dimensioning and Tolerancing (GD&T)

Work Experience

Turning Lathe Tender

- Inspected and measured finished products using precision measuring instruments

- Followed safety protocols and maintained a clean and well-organized work area

- Successfully achieved production targets while adhering to quality standards

- Performed routine maintenance and troubleshooting on lathe equipment

Turning Lathe Tender

- Utilized advanced cutting techniques to achieve high precision and tolerance levels on complex components

- Operated various CNC turning lathes, including multi-axis and horizontal machines

- Programmed and optimized CNC lathe programs using industry-standard G-code

- Set up and maintained lathe machines, including tooling selections and alignments

Accomplishments

- Reduced cycle time by 10% through optimizing cutting tool selection and machine parameters

- Improved product quality by implementing proactive maintenance routines to minimize machine downtime

- Ensured accuracy and precision in machining complex components by calibrating and maintaining turning lathes

- Reduced material waste by utilizing lean manufacturing principles to optimize material utilization

- Trained new lathe operators on safe operating procedures and best practices

Awards

- Recognized for exceeding production targets by 25% in consecutive quarters

- Received award for maintaining zero defects in highvolume production runs

- Honored for suggesting and implementing safety improvements that reduced workplace hazards

Certificates

- American Society of Mechanical Engineers (ASME) B16.5 Flange Code

- American Welding Society (AWS) Certified Welder

- Certified Machinist

- CNC Programmer Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Turning Lathe Tender

- Highlight your experience operating and programming turning lathes.

- Showcase your proficiency in blueprint reading, CNC programming, and GD&T.

- Emphasize your attention to detail and commitment to quality.

- Include quantifiable results to demonstrate your impact on the manufacturing process.

Essential Experience Highlights for a Strong Turning Lathe Tender Resume

- Set up and operate turning lathes according to blueprints and specifications

- Monitor and adjust lathe settings to ensure accuracy and precision

- Inspect finished parts to ensure they meet quality standards

- Maintain and calibrate lathes and tooling

- Follow safety protocols and maintain a clean and organized work area

- Develop and implement CNC programs to automate lathe operations

- Troubleshoot and resolve technical issues related to lathes and CNC programs

Frequently Asked Questions (FAQ’s) For Turning Lathe Tender

What is the primary role of a Turning Lathe Tender?

The primary role of a Turning Lathe Tender is to operate and maintain turning lathes, ensuring precision and quality in the production of complex components.

What are the essential skills required for this position?

Essential skills for a Turning Lathe Tender include blueprint reading, CAD software proficiency, CNC programming, dimensional measurement, G-Code programming, and geometric dimensioning and tolerancing (GD&T).

What is the typical work environment for a Turning Lathe Tender?

Turning Lathe Tenders typically work in manufacturing facilities, operating lathes in a production environment. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production deadlines.

What are the career advancement opportunities for a Turning Lathe Tender?

With experience and additional training, Turning Lathe Tenders can advance to positions such as CNC Programmer, Manufacturing Engineer, or Supervisor. They may also specialize in a particular area of lathe operation, such as tool and die making or precision machining.

How can I prepare for a career as a Turning Lathe Tender?

To prepare for a career as a Turning Lathe Tender, you can complete an associate’s degree or certificate program in manufacturing or a related field. You can also gain experience through apprenticeships or internships in the manufacturing industry.

What is the average salary for a Turning Lathe Tender?

The average salary for a Turning Lathe Tender varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Turning Lathe Tenders was $47,760 in May 2020.