Are you a seasoned Upset Operator seeking a new career path? Discover our professionally built Upset Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

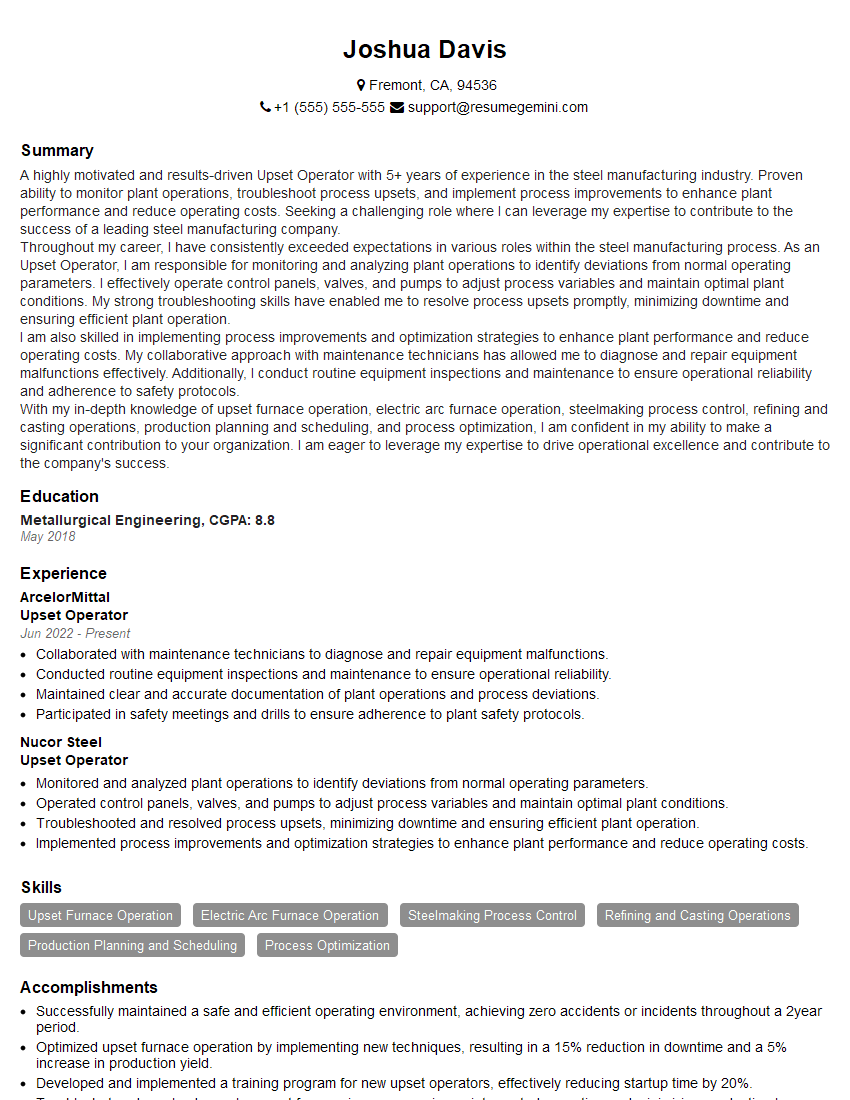

Joshua Davis

Upset Operator

Summary

A highly motivated and results-driven Upset Operator with 5+ years of experience in the steel manufacturing industry. Proven ability to monitor plant operations, troubleshoot process upsets, and implement process improvements to enhance plant performance and reduce operating costs. Seeking a challenging role where I can leverage my expertise to contribute to the success of a leading steel manufacturing company.

Throughout my career, I have consistently exceeded expectations in various roles within the steel manufacturing process. As an Upset Operator, I am responsible for monitoring and analyzing plant operations to identify deviations from normal operating parameters. I effectively operate control panels, valves, and pumps to adjust process variables and maintain optimal plant conditions. My strong troubleshooting skills have enabled me to resolve process upsets promptly, minimizing downtime and ensuring efficient plant operation.

I am also skilled in implementing process improvements and optimization strategies to enhance plant performance and reduce operating costs. My collaborative approach with maintenance technicians has allowed me to diagnose and repair equipment malfunctions effectively. Additionally, I conduct routine equipment inspections and maintenance to ensure operational reliability and adherence to safety protocols.

With my in-depth knowledge of upset furnace operation, electric arc furnace operation, steelmaking process control, refining and casting operations, production planning and scheduling, and process optimization, I am confident in my ability to make a significant contribution to your organization. I am eager to leverage my expertise to drive operational excellence and contribute to the company’s success.

Education

Metallurgical Engineering

May 2018

Skills

- Upset Furnace Operation

- Electric Arc Furnace Operation

- Steelmaking Process Control

- Refining and Casting Operations

- Production Planning and Scheduling

- Process Optimization

Work Experience

Upset Operator

- Collaborated with maintenance technicians to diagnose and repair equipment malfunctions.

- Conducted routine equipment inspections and maintenance to ensure operational reliability.

- Maintained clear and accurate documentation of plant operations and process deviations.

- Participated in safety meetings and drills to ensure adherence to plant safety protocols.

Upset Operator

- Monitored and analyzed plant operations to identify deviations from normal operating parameters.

- Operated control panels, valves, and pumps to adjust process variables and maintain optimal plant conditions.

- Troubleshooted and resolved process upsets, minimizing downtime and ensuring efficient plant operation.

- Implemented process improvements and optimization strategies to enhance plant performance and reduce operating costs.

Accomplishments

- Successfully maintained a safe and efficient operating environment, achieving zero accidents or incidents throughout a 2year period.

- Optimized upset furnace operation by implementing new techniques, resulting in a 15% reduction in downtime and a 5% increase in production yield.

- Developed and implemented a training program for new upset operators, effectively reducing startup time by 20%.

- Troubleshot and resolved complex upset furnace issues, ensuring uninterrupted operation and minimizing production losses.

- Collaborated with engineers to design and implement process improvements, resulting in a 10% increase in furnace efficiency.

Certificates

- Certified Upset Operator (CUO)

- National Institute for Metalworking Skills (NIMS) Level III in Upset Forging

- American Welding Society (AWS) Certified Welder

- Occupational Safety and Health Administration (OSHA) 10-Hour General Industry Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Upset Operator

Highlight your technical skills and experience.

Emphasize your proficiency in upset furnace operation, electric arc furnace operation, steelmaking process control, and other relevant technical skills. Quantify your accomplishments whenever possible to demonstrate your impact on plant performance.

Showcase your problem-solving abilities.

Provide specific examples of how you have successfully troubleshooted and resolved process upsets. Describe the steps you took to identify the root cause of the problem and the actions you implemented to resolve it.

Demonstrate your commitment to safety.

Highlight your adherence to safety protocols and your participation in safety meetings and drills. Emphasize your understanding of safety regulations and your commitment to maintaining a safe work environment.

Use strong action verbs.

Throughout your resume, use strong action verbs that convey your accomplishments and responsibilities. Avoid passive language and focus on the specific actions you have taken to contribute to the success of your organization.

Essential Experience Highlights for a Strong Upset Operator Resume

- Monitor and analyze plant operations to identify deviations from normal operating parameters.

- Operate control panels, valves, and pumps to adjust process variables and maintain optimal plant conditions.

- Troubleshoot and resolve process upsets, minimizing downtime and ensuring efficient plant operation.

- Implement process improvements and optimization strategies to enhance plant performance and reduce operating costs.

- Collaborate with maintenance technicians to diagnose and repair equipment malfunctions.

- Conduct routine equipment inspections and maintenance to ensure operational reliability.

- Maintain clear and accurate documentation of plant operations and process deviations.

Frequently Asked Questions (FAQ’s) For Upset Operator

What is the role of an Upset Operator?

An Upset Operator is responsible for monitoring and controlling the operation of upset furnaces and electric arc furnaces in a steel manufacturing plant. They adjust process variables, troubleshoot and resolve process upsets, and implement process improvements to enhance plant performance and reduce operating costs.

What are the key skills required for an Upset Operator?

Key skills for an Upset Operator include: upset furnace operation, electric arc furnace operation, steelmaking process control, refining and casting operations, production planning and scheduling, process optimization, troubleshooting, and problem-solving.

What is the typical work environment for an Upset Operator?

Upset Operators typically work in steel manufacturing plants, operating in close proximity to furnaces and other industrial equipment. They may be exposed to heat, noise, and dust, and may work shifts, including nights and weekends.

What are the career prospects for an Upset Operator?

Upset Operators with experience and a strong track record may advance to supervisory or management roles within the steel manufacturing industry. They may also specialize in a particular area of steelmaking, such as upset furnace operation or electric arc furnace operation.

What is the average salary for an Upset Operator?

The average salary for an Upset Operator in the United States is around $75,000 per year. However, salaries may vary depending on experience, location, and company size.

What are the educational requirements for an Upset Operator?

Most Upset Operators have a high school diploma or equivalent. However, some employers may prefer candidates with a degree in a related field, such as metallurgical engineering or materials science.

What are the certifications available for Upset Operators?

There are several certifications available for Upset Operators, including the Certified Upset Operator (CUO) certification from the Steel Manufacturers Association (SMA).