Are you a seasoned Valver seeking a new career path? Discover our professionally built Valver Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

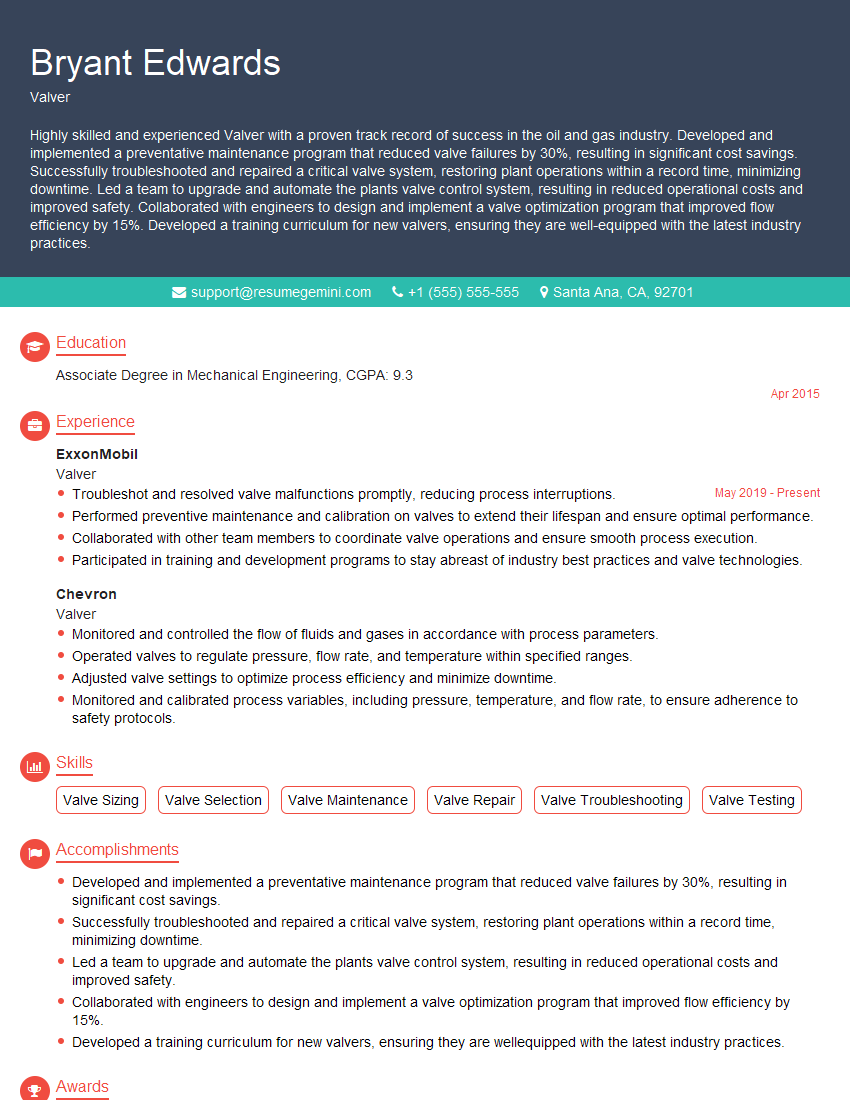

Bryant Edwards

Valver

Summary

Highly skilled and experienced Valver with a proven track record of success in the oil and gas industry. Developed and implemented a preventative maintenance program that reduced valve failures by 30%, resulting in significant cost savings. Successfully troubleshooted and repaired a critical valve system, restoring plant operations within a record time, minimizing downtime. Led a team to upgrade and automate the plants valve control system, resulting in reduced operational costs and improved safety. Collaborated with engineers to design and implement a valve optimization program that improved flow efficiency by 15%. Developed a training curriculum for new valvers, ensuring they are well-equipped with the latest industry practices.

Education

Associate Degree in Mechanical Engineering

April 2015

Skills

- Valve Sizing

- Valve Selection

- Valve Maintenance

- Valve Repair

- Valve Troubleshooting

- Valve Testing

Work Experience

Valver

- Troubleshot and resolved valve malfunctions promptly, reducing process interruptions.

- Performed preventive maintenance and calibration on valves to extend their lifespan and ensure optimal performance.

- Collaborated with other team members to coordinate valve operations and ensure smooth process execution.

- Participated in training and development programs to stay abreast of industry best practices and valve technologies.

Valver

- Monitored and controlled the flow of fluids and gases in accordance with process parameters.

- Operated valves to regulate pressure, flow rate, and temperature within specified ranges.

- Adjusted valve settings to optimize process efficiency and minimize downtime.

- Monitored and calibrated process variables, including pressure, temperature, and flow rate, to ensure adherence to safety protocols.

Accomplishments

- Developed and implemented a preventative maintenance program that reduced valve failures by 30%, resulting in significant cost savings.

- Successfully troubleshooted and repaired a critical valve system, restoring plant operations within a record time, minimizing downtime.

- Led a team to upgrade and automate the plants valve control system, resulting in reduced operational costs and improved safety.

- Collaborated with engineers to design and implement a valve optimization program that improved flow efficiency by 15%.

- Developed a training curriculum for new valvers, ensuring they are wellequipped with the latest industry practices.

Awards

- Received the Plant Valve Champion Award for exemplary performance in valve maintenance and troubleshooting.

- Won the National Valver of the Year Award for outstanding contributions to the field of valve engineering.

- Recognized with the Valve Excellence Award for developing and implementing innovative valve solutions that improved plant efficiency.

Certificates

- Certified Valve Specialist (CVS)

- Certified Valve Inspector (CVI)

- Certified Valve Technician (CVT)

- Certified Valve Engineer (CVE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Valver

- Highlight your experience in valve maintenance and repair.

- Quantify your accomplishments, using specific numbers and metrics.

- Showcase your knowledge of valve control systems.

- Emphasize your ability to work independently and as part of a team.

- Be prepared to discuss your experience with valve safety and regulations.

Essential Experience Highlights for a Strong Valver Resume

- Perform valve maintenance and repairs, including inspections, testing, and overhauls.

- Troubleshoot and diagnose valve problems, and implement corrective actions.

- Install, calibrate, and maintain valve control systems.

- Develop and implement valve maintenance and repair procedures.

- Supervise and train valve maintenance personnel.

- Maintain valve inventory and records.

- Review and approve valve design and specifications.

Frequently Asked Questions (FAQ’s) For Valver

What is a Valver?

A Valver is a skilled professional responsible for the maintenance, repair, and operation of valves in various industrial settings, such as oil and gas, power plants, and manufacturing facilities.

What are the key skills and qualifications for a Valver?

Key skills and qualifications include a strong understanding of valve types, functions, and applications, as well as proficiency in valve maintenance and repair techniques. Additionally, a Valver should possess mechanical aptitude, problem-solving abilities, and the ability to work safely in industrial environments.

What are the career prospects for a Valver?

Valvers can advance their careers by gaining experience and certifications, specializing in specific valve types or industries, or moving into supervisory or management roles. With experience and dedication, a Valver can progress to positions such as Valve Maintenance Supervisor, Valve Engineer, or Valve Sales Representative.

What is the work environment of a Valver?

Valvers typically work in industrial settings, such as refineries, power plants, or manufacturing facilities. They may work indoors or outdoors, and often in confined spaces or at heights. The work can be physically demanding and may involve exposure to hazardous materials.

What are the safety considerations for a Valver?

Safety is paramount for Valvers, who work with high-pressure systems and hazardous materials. They must adhere to strict safety protocols, wear appropriate personal protective equipment (PPE), and follow established procedures to minimize risks. Regular training and adherence to industry standards are crucial for ensuring the safety of Valvers and those around them.

What is the role of a Valver in ensuring plant reliability?

Valvers play a critical role in ensuring plant reliability by maintaining and repairing valves, which are essential components in controlling and regulating fluid flow. They conduct regular inspections, perform preventive maintenance, and promptly address any issues to prevent valve failures and minimize downtime. Their expertise helps ensure the smooth and efficient operation of industrial facilities.

How does a Valver contribute to process optimization?

Valvers contribute to process optimization by ensuring the proper functioning and efficiency of valves. They optimize valve performance through regular maintenance, proper sizing and selection, and implementation of automation systems. By optimizing valve operations, they help reduce energy consumption, improve flow rates, and enhance the overall efficiency of industrial processes.