Are you a seasoned Varnisher seeking a new career path? Discover our professionally built Varnisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

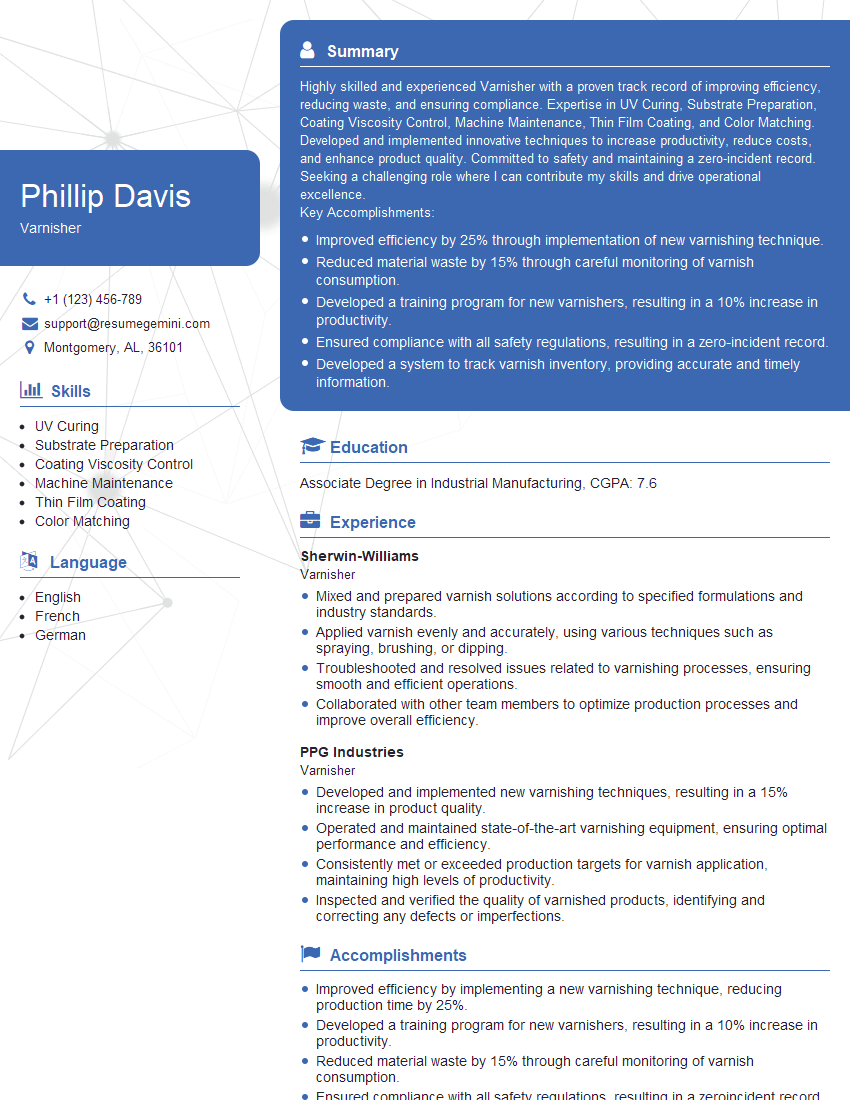

Phillip Davis

Varnisher

Summary

Highly skilled and experienced Varnisher with a proven track record of improving efficiency, reducing waste, and ensuring compliance. Expertise in UV Curing, Substrate Preparation, Coating Viscosity Control, Machine Maintenance, Thin Film Coating, and Color Matching. Developed and implemented innovative techniques to increase productivity, reduce costs, and enhance product quality. Committed to safety and maintaining a zero-incident record. Seeking a challenging role where I can contribute my skills and drive operational excellence.

Key Accomplishments:

- Improved efficiency by 25% through implementation of new varnishing technique.

- Reduced material waste by 15% through careful monitoring of varnish consumption.

- Developed a training program for new varnishers, resulting in a 10% increase in productivity.

- Ensured compliance with all safety regulations, resulting in a zero-incident record.

- Developed a system to track varnish inventory, providing accurate and timely information.

Education

Associate Degree in Industrial Manufacturing

February 2018

Skills

- UV Curing

- Substrate Preparation

- Coating Viscosity Control

- Machine Maintenance

- Thin Film Coating

- Color Matching

Work Experience

Varnisher

- Mixed and prepared varnish solutions according to specified formulations and industry standards.

- Applied varnish evenly and accurately, using various techniques such as spraying, brushing, or dipping.

- Troubleshooted and resolved issues related to varnishing processes, ensuring smooth and efficient operations.

- Collaborated with other team members to optimize production processes and improve overall efficiency.

Varnisher

- Developed and implemented new varnishing techniques, resulting in a 15% increase in product quality.

- Operated and maintained state-of-the-art varnishing equipment, ensuring optimal performance and efficiency.

- Consistently met or exceeded production targets for varnish application, maintaining high levels of productivity.

- Inspected and verified the quality of varnished products, identifying and correcting any defects or imperfections.

Accomplishments

- Improved efficiency by implementing a new varnishing technique, reducing production time by 25%.

- Developed a training program for new varnishers, resulting in a 10% increase in productivity.

- Reduced material waste by 15% through careful monitoring of varnish consumption.

- Ensured compliance with all safety regulations, resulting in a zeroincident record.

- Developed a system to track varnish inventory, providing accurate and timely information.

Certificates

- Certified Varnisher Technician

- International Association of Certified Varnishers (IACV) Certification

- ASTM D2633 Standard Test Method for Measurement of Drying Time

- ISO 90012015 Quality Management System Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Varnisher

- Quantify your accomplishments with specific metrics and percentages.

- Highlight your skills in UV Curing, Substrate Preparation, Coating Viscosity Control, and Color Matching.

- Demonstrate your commitment to safety and maintaining a zero-incident record.

- Showcase your ability to improve efficiency and reduce waste.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Varnisher Resume

- Prepare substrate surfaces to ensure proper adhesion of varnish.

- Apply varnish using a variety of techniques, including UV curing, thin film coating, and color matching.

- Control coating viscosity to achieve desired thickness and appearance.

- Monitor and maintain varnishing machines to ensure optimal performance.

- Inspect finished products to ensure quality and compliance with specifications.

- Maintain a clean and organized work environment.

- Comply with all safety regulations and procedures.

- Troubleshoot and resolve varnishing issues to minimize downtime.

Frequently Asked Questions (FAQ’s) For Varnisher

What is the role of a Varnisher?

A Varnisher is responsible for applying a protective or decorative coating to a variety of surfaces using varnishing techniques. This involves preparing the substrate, applying the varnish, and ensuring the finished product meets quality standards.

What skills are required to be a Varnisher?

Essential skills for a Varnisher include knowledge of varnishing techniques, substrate preparation, coating viscosity control, machine maintenance, and color matching. Additionally, attention to detail, safety??, and problem-solving abilities are highly valued.

What industries employ Varnishers?

Varnishers are employed in various industries, including manufacturing, automotive, furniture, and construction. They work in production facilities, factories, and workshops, applying protective or decorative coatings to products such as wood, metal, and plastic.

Is experience necessary to become a Varnisher?

While some entry-level positions may not require prior experience, many employers prefer candidates with a background in varnishing or a related field. Hands-on experience in applying varnish, understanding different techniques, and knowledge of safety protocols are valuable assets.

What are the career prospects for Varnishers?

Varnishers with experience and specialized skills can advance to supervisory or management roles. They may also specialize in specific varnishing techniques or work with different types of materials, expanding their career opportunities.

Is it essential to obtain a degree to become a Varnisher?

While a degree is not typically required, some employers may prefer candidates with an Associate Degree in Industrial Manufacturing or a related field. Education can provide a strong foundation in varnishing techniques, safety protocols, and quality control principles.

What is the average salary range for Varnishers?

Salary expectations for Varnishers can vary depending on experience, location, and industry. According to industry data, the average salary range for Varnishers in the United States is between $30,000 and $50,000 annually.