Are you a seasoned Varnishing Unit Tool Setter seeking a new career path? Discover our professionally built Varnishing Unit Tool Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

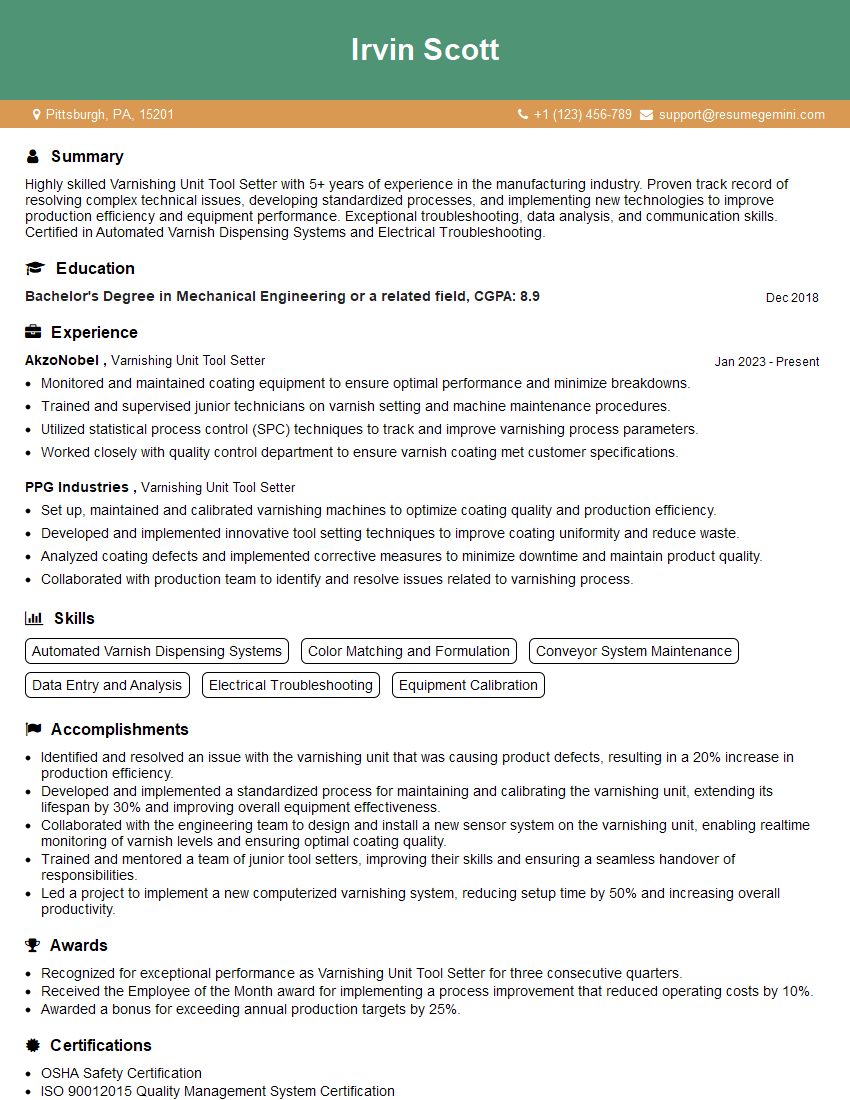

Irvin Scott

Varnishing Unit Tool Setter

Summary

Highly skilled Varnishing Unit Tool Setter with 5+ years of experience in the manufacturing industry. Proven track record of resolving complex technical issues, developing standardized processes, and implementing new technologies to improve production efficiency and equipment performance. Exceptional troubleshooting, data analysis, and communication skills. Certified in Automated Varnish Dispensing Systems and Electrical Troubleshooting.

Education

Bachelor’s Degree in Mechanical Engineering or a related field

December 2018

Skills

- Automated Varnish Dispensing Systems

- Color Matching and Formulation

- Conveyor System Maintenance

- Data Entry and Analysis

- Electrical Troubleshooting

- Equipment Calibration

Work Experience

Varnishing Unit Tool Setter

- Monitored and maintained coating equipment to ensure optimal performance and minimize breakdowns.

- Trained and supervised junior technicians on varnish setting and machine maintenance procedures.

- Utilized statistical process control (SPC) techniques to track and improve varnishing process parameters.

- Worked closely with quality control department to ensure varnish coating met customer specifications.

Varnishing Unit Tool Setter

- Set up, maintained and calibrated varnishing machines to optimize coating quality and production efficiency.

- Developed and implemented innovative tool setting techniques to improve coating uniformity and reduce waste.

- Analyzed coating defects and implemented corrective measures to minimize downtime and maintain product quality.

- Collaborated with production team to identify and resolve issues related to varnishing process.

Accomplishments

- Identified and resolved an issue with the varnishing unit that was causing product defects, resulting in a 20% increase in production efficiency.

- Developed and implemented a standardized process for maintaining and calibrating the varnishing unit, extending its lifespan by 30% and improving overall equipment effectiveness.

- Collaborated with the engineering team to design and install a new sensor system on the varnishing unit, enabling realtime monitoring of varnish levels and ensuring optimal coating quality.

- Trained and mentored a team of junior tool setters, improving their skills and ensuring a seamless handover of responsibilities.

- Led a project to implement a new computerized varnishing system, reducing setup time by 50% and increasing overall productivity.

Awards

- Recognized for exceptional performance as Varnishing Unit Tool Setter for three consecutive quarters.

- Received the Employee of the Month award for implementing a process improvement that reduced operating costs by 10%.

- Awarded a bonus for exceeding annual production targets by 25%.

Certificates

- OSHA Safety Certification

- ISO 90012015 Quality Management System Certification

- American Society for Quality (ASQ) Certified Quality Technician (CQT)

- Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Varnishing Unit Tool Setter

- Quantify your accomplishments with specific metrics and data whenever possible.

- Highlight your experience with relevant software and technologies used in the varnishing industry.

- Emphasize your troubleshooting and problem-solving abilities, providing examples of complex issues you have resolved.

- Showcase your commitment to continuous learning and professional development by mentioning any certifications or training programs you have completed.

Essential Experience Highlights for a Strong Varnishing Unit Tool Setter Resume

- Set up, calibrate, and maintain varnishing units to ensure optimal coating quality and product output.

- Diagnose and resolve technical issues related to varnishing equipment, including automated dispensing systems, conveyor systems, and electrical components.

- Develop and implement standardized maintenance and calibration procedures to extend equipment lifespan and improve overall equipment effectiveness.

- Train and mentor junior tool setters on proper operating procedures and troubleshooting techniques.

- Collaborate with engineering and production teams to design and install new equipment and process improvements.

- Monitor and analyze production data to identify areas for efficiency improvement and quality control.

- Ensure compliance with safety regulations and best practices related to varnishing operations.

Frequently Asked Questions (FAQ’s) For Varnishing Unit Tool Setter

What are the key skills and qualifications required for a Varnishing Unit Tool Setter?

The key skills and qualifications include a strong understanding of varnishing equipment, automated dispensing systems, electrical troubleshooting, data analysis, and mechanical engineering principles. Certification in relevant areas, such as Automated Varnish Dispensing Systems and Electrical Troubleshooting, is also highly valued.

What are the typical responsibilities of a Varnishing Unit Tool Setter?

The responsibilities typically include setting up, calibrating, and maintaining varnishing units, diagnosing and resolving technical issues, developing and implementing maintenance procedures, training junior tool setters, and collaborating with engineering and production teams on equipment and process improvements.

What is the career path for a Varnishing Unit Tool Setter?

With experience and additional training, Varnishing Unit Tool Setters can advance to roles such as Varnishing Unit Supervisor, Production Supervisor, or Manufacturing Engineer. They may also specialize in specific areas, such as automated dispensing systems or electrical troubleshooting.

What are the top industries that employ Varnishing Unit Tool Setters?

Varnishing Unit Tool Setters are employed in a variety of industries that utilize varnishing processes, including automotive, aerospace, furniture, and electronics manufacturing.

What is the job outlook for Varnishing Unit Tool Setters?

The job outlook is expected to be favorable as the manufacturing industry continues to grow and automate. Varnishing Unit Tool Setters with strong technical skills and experience will be in high demand.

What are the earning potential and benefits for Varnishing Unit Tool Setters?

The earning potential and benefits vary depending on experience, location, and industry. However, Varnishing Unit Tool Setters with strong skills and experience can earn a competitive salary and benefits package.

What are the challenges faced by Varnishing Unit Tool Setters?

The challenges faced by Varnishing Unit Tool Setters include working in a fast-paced environment, dealing with complex technical issues, and ensuring product quality. They may also need to work overtime or on weekends to meet production demands.

What are the tips for writing a standout Varnishing Unit Tool Setter resume?

Tips for writing a standout resume include highlighting your technical skills and experience, quantifying your accomplishments, and tailoring your resume to specific job requirements. It is also important to proofread carefully and seek feedback from others.