Are you a seasoned Veneer Cutter seeking a new career path? Discover our professionally built Veneer Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

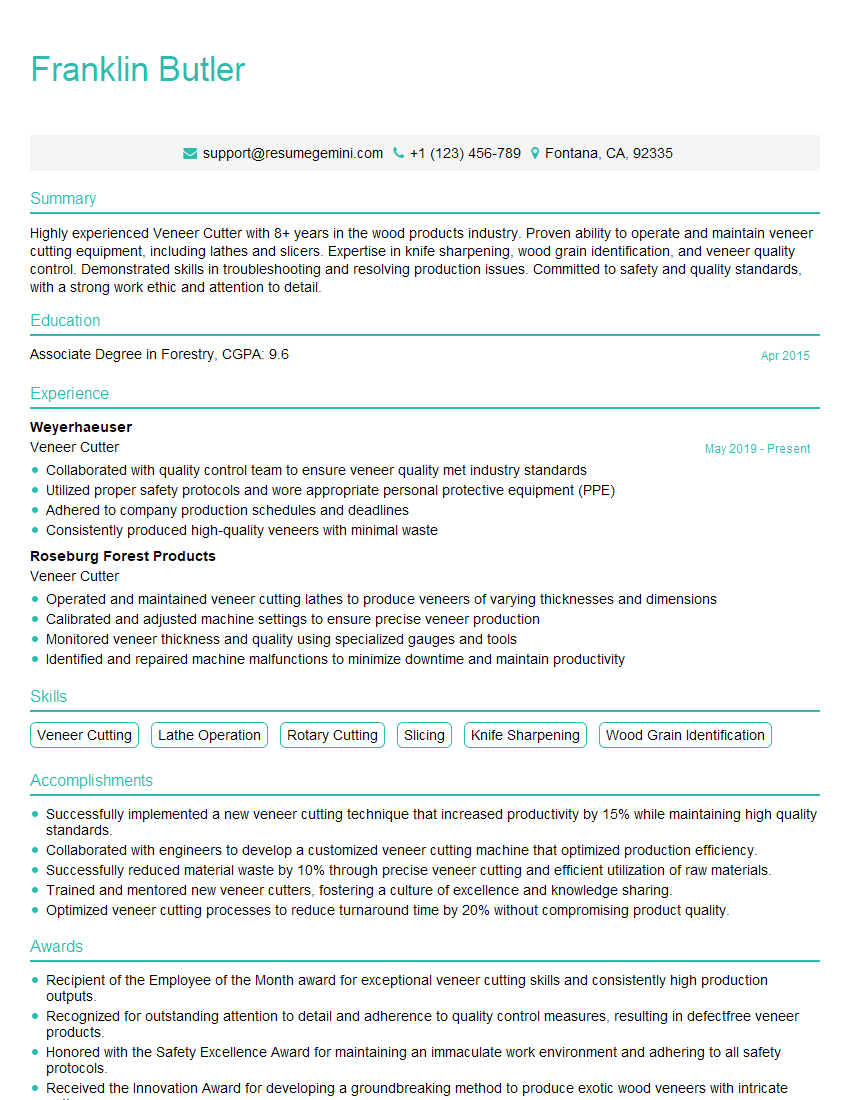

Franklin Butler

Veneer Cutter

Summary

Highly experienced Veneer Cutter with 8+ years in the wood products industry. Proven ability to operate and maintain veneer cutting equipment, including lathes and slicers. Expertise in knife sharpening, wood grain identification, and veneer quality control. Demonstrated skills in troubleshooting and resolving production issues. Committed to safety and quality standards, with a strong work ethic and attention to detail.

Education

Associate Degree in Forestry

April 2015

Skills

- Veneer Cutting

- Lathe Operation

- Rotary Cutting

- Slicing

- Knife Sharpening

- Wood Grain Identification

Work Experience

Veneer Cutter

- Collaborated with quality control team to ensure veneer quality met industry standards

- Utilized proper safety protocols and wore appropriate personal protective equipment (PPE)

- Adhered to company production schedules and deadlines

- Consistently produced high-quality veneers with minimal waste

Veneer Cutter

- Operated and maintained veneer cutting lathes to produce veneers of varying thicknesses and dimensions

- Calibrated and adjusted machine settings to ensure precise veneer production

- Monitored veneer thickness and quality using specialized gauges and tools

- Identified and repaired machine malfunctions to minimize downtime and maintain productivity

Accomplishments

- Successfully implemented a new veneer cutting technique that increased productivity by 15% while maintaining high quality standards.

- Collaborated with engineers to develop a customized veneer cutting machine that optimized production efficiency.

- Successfully reduced material waste by 10% through precise veneer cutting and efficient utilization of raw materials.

- Trained and mentored new veneer cutters, fostering a culture of excellence and knowledge sharing.

- Optimized veneer cutting processes to reduce turnaround time by 20% without compromising product quality.

Awards

- Recipient of the Employee of the Month award for exceptional veneer cutting skills and consistently high production outputs.

- Recognized for outstanding attention to detail and adherence to quality control measures, resulting in defectfree veneer products.

- Honored with the Safety Excellence Award for maintaining an immaculate work environment and adhering to all safety protocols.

- Received the Innovation Award for developing a groundbreaking method to produce exotic wood veneers with intricate patterns.

Certificates

- Certified Veneer Cutter

- Safety Certification

- First Aid and CPR

- Material Handling Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Veneer Cutter

- Highlight your experience in operating and maintaining veneer cutting equipment, especially if you have experience with specific types of machines.

- Quantify your accomplishments whenever possible, such as the number of veneers produced per hour or the reduction in waste achieved through your efforts.

- Emphasize your knowledge of wood grain identification and veneer grading, as this is essential for producing high-quality products.

- Showcase your troubleshooting and problem-solving skills, as these are critical in a manufacturing environment.

Essential Experience Highlights for a Strong Veneer Cutter Resume

- Operate and maintain veneer cutting machinery, including lathes and slicers, to produce high-quality veneers.

- Inspect and measure logs to determine their suitability for veneer production.

- Sharpen and maintain knives used in veneer cutting operations.

- Identify and grade veneers based on wood species, grain pattern, and other quality factors.

- Troubleshoot and resolve production issues related to veneer cutting equipment and processes.

- Comply with safety regulations and maintain a clean and organized work environment.

- Train and supervise junior veneer cutters and assist in the development of new products.

Frequently Asked Questions (FAQ’s) For Veneer Cutter

What is the role of a Veneer Cutter?

A Veneer Cutter operates and maintains veneer cutting machinery to produce thin sheets of wood used in various applications such as furniture, cabinetry, and musical instruments.

What skills are required to be a successful Veneer Cutter?

Essential skills include machine operation, knife sharpening, wood grain identification, and quality control.

What is the career outlook for Veneer Cutters?

The demand for Veneer Cutters is expected to grow as the construction and furniture industries continue to expand.

What is the average salary for a Veneer Cutter?

The average salary for Veneer Cutters in the United States is around $45,000 per year.

What are the working conditions like for Veneer Cutters?

Veneer Cutters typically work in manufacturing plants and may be exposed to noise, dust, and chemicals.

Are there any certifications or licenses required to become a Veneer Cutter?

There are no specific certifications or licenses required, but training and experience in wood products manufacturing is essential.

What is the job outlook for Veneer Cutters?

The job outlook for Veneer Cutters is expected to remain stable over the next decade.