Are you a seasoned Veneer Jointer Operator seeking a new career path? Discover our professionally built Veneer Jointer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

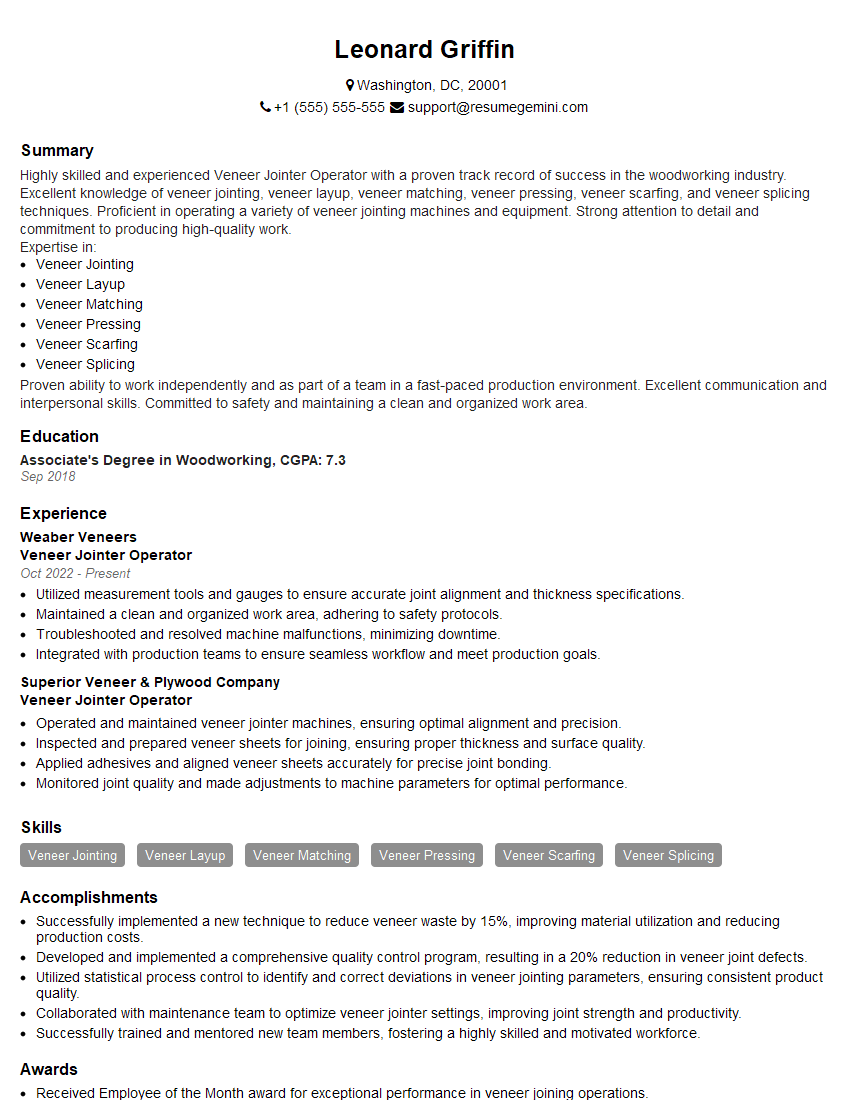

Leonard Griffin

Veneer Jointer Operator

Summary

Highly skilled and experienced Veneer Jointer Operator with a proven track record of success in the woodworking industry. Excellent knowledge of veneer jointing, veneer layup, veneer matching, veneer pressing, veneer scarfing, and veneer splicing techniques. Proficient in operating a variety of veneer jointing machines and equipment. Strong attention to detail and commitment to producing high-quality work.

Expertise in:

- Veneer Jointing

- Veneer Layup

- Veneer Matching

- Veneer Pressing

- Veneer Scarfing

- Veneer Splicing

Proven ability to work independently and as part of a team in a fast-paced production environment. Excellent communication and interpersonal skills. Committed to safety and maintaining a clean and organized work area.

Education

Associate’s Degree in Woodworking

September 2018

Skills

- Veneer Jointing

- Veneer Layup

- Veneer Matching

- Veneer Pressing

- Veneer Scarfing

- Veneer Splicing

Work Experience

Veneer Jointer Operator

- Utilized measurement tools and gauges to ensure accurate joint alignment and thickness specifications.

- Maintained a clean and organized work area, adhering to safety protocols.

- Troubleshooted and resolved machine malfunctions, minimizing downtime.

- Integrated with production teams to ensure seamless workflow and meet production goals.

Veneer Jointer Operator

- Operated and maintained veneer jointer machines, ensuring optimal alignment and precision.

- Inspected and prepared veneer sheets for joining, ensuring proper thickness and surface quality.

- Applied adhesives and aligned veneer sheets accurately for precise joint bonding.

- Monitored joint quality and made adjustments to machine parameters for optimal performance.

Accomplishments

- Successfully implemented a new technique to reduce veneer waste by 15%, improving material utilization and reducing production costs.

- Developed and implemented a comprehensive quality control program, resulting in a 20% reduction in veneer joint defects.

- Utilized statistical process control to identify and correct deviations in veneer jointing parameters, ensuring consistent product quality.

- Collaborated with maintenance team to optimize veneer jointer settings, improving joint strength and productivity.

- Successfully trained and mentored new team members, fostering a highly skilled and motivated workforce.

Awards

- Received Employee of the Month award for exceptional performance in veneer joining operations.

- Recognized with a Safety Excellence Award for maintaining a spotless safety record while operating veneer jointers.

- Received Top Performer Award for consistently exceeding production targets and maintaining highquality standards.

- Honored with a Continuous Improvement Award for identifying and implementing process enhancements that increased productivity.

Certificates

- Veneer Jointing Operator Certification

- Veneer Layup Operator Certification

- Veneer Pressing Operator Certification

- Veneer Scarfing Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Veneer Jointer Operator

- Tailor your resume to the specific job you are applying for. Highlight your skills and experience that are most relevant to the position.

- Quantify your accomplishments whenever possible. For example, instead of saying “Operated a veneer jointing machine,” you could say, “Operated a veneer jointing machine to produce over 1,000 high-quality veneer joints per day.”

- Proofread your resume carefully before submitting it. Make sure there are no errors in grammar or spelling.

- Get feedback on your resume from a career counselor or another professional.

- Don’t be afraid to sell yourself on your resume. Highlight your unique skills and experience that set you apart from other candidates.

Essential Experience Highlights for a Strong Veneer Jointer Operator Resume

- Operate and maintain veneer jointing machines to produce high-quality veneer joints.

- Inspect veneers for defects and determine the best methods for jointing.

- Set up and adjust veneer jointing machines according to specifications.

- Ensure that veneer joints meet required tolerances and specifications.

- Monitor the production process to identify and correct any potential issues.

- Maintain a clean and organized work area to ensure safety and efficiency.

- Follow all safety regulations and procedures.

Frequently Asked Questions (FAQ’s) For Veneer Jointer Operator

What is a Veneer Jointer Operator?

A Veneer Jointer Operator is responsible for operating and maintaining veneer jointing machines to produce high-quality veneer joints. They inspect veneers for defects and determine the best methods for jointing, set up and adjust veneer jointing machines according to specifications, and ensure that veneer joints meet required tolerances and specifications.

What are the qualifications for a Veneer Jointer Operator?

Qualifications for a Veneer Jointer Operator typically include a high school diploma or equivalent, along with experience in the woodworking industry. Some employers may prefer candidates with an Associate’s Degree in Woodworking or a related field.

What are the skills required for a Veneer Jointer Operator?

Skills required for a Veneer Jointer Operator include the ability to operate and maintain veneer jointing machines, inspect veneers for defects, determine the best methods for jointing, and set up and adjust veneer jointing machines according to specifications. They must also be able to ensure that veneer joints meet required tolerances and specifications, monitor the production process to identify and correct any potential issues, and maintain a clean and organized work area.

What is the work environment of a Veneer Jointer Operator?

Veneer Jointer Operators typically work in a factory or manufacturing setting. They may work in a team environment or independently. The work can be repetitive, but it is also important to be able to pay attention to detail and to follow safety regulations.

What is the salary of a Veneer Jointer Operator?

The salary of a Veneer Jointer Operator can vary depending on their experience, skills, and location. According to Indeed.com, the average salary for a Veneer Jointer Operator in the United States is $45,000 per year.

What is the job outlook for Veneer Jointer Operators?

The job outlook for Veneer Jointer Operators is expected to be good over the next few years. The demand for veneer products is expected to increase, which will lead to an increase in demand for Veneer Jointer Operators.

What are the career advancement opportunities for Veneer Jointer Operators?

Veneer Jointer Operators can advance their careers by becoming supervisors or managers. They may also move into other areas of the woodworking industry, such as furniture making or cabinet making.

What are the benefits of working as a Veneer Jointer Operator?

The benefits of working as a Veneer Jointer Operator can include a steady income, opportunities for advancement, and the satisfaction of working with wood. Veneer Jointer Operators also have the opportunity to learn new skills and to work with a variety of people.