Are you a seasoned Veneer Press Operator seeking a new career path? Discover our professionally built Veneer Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

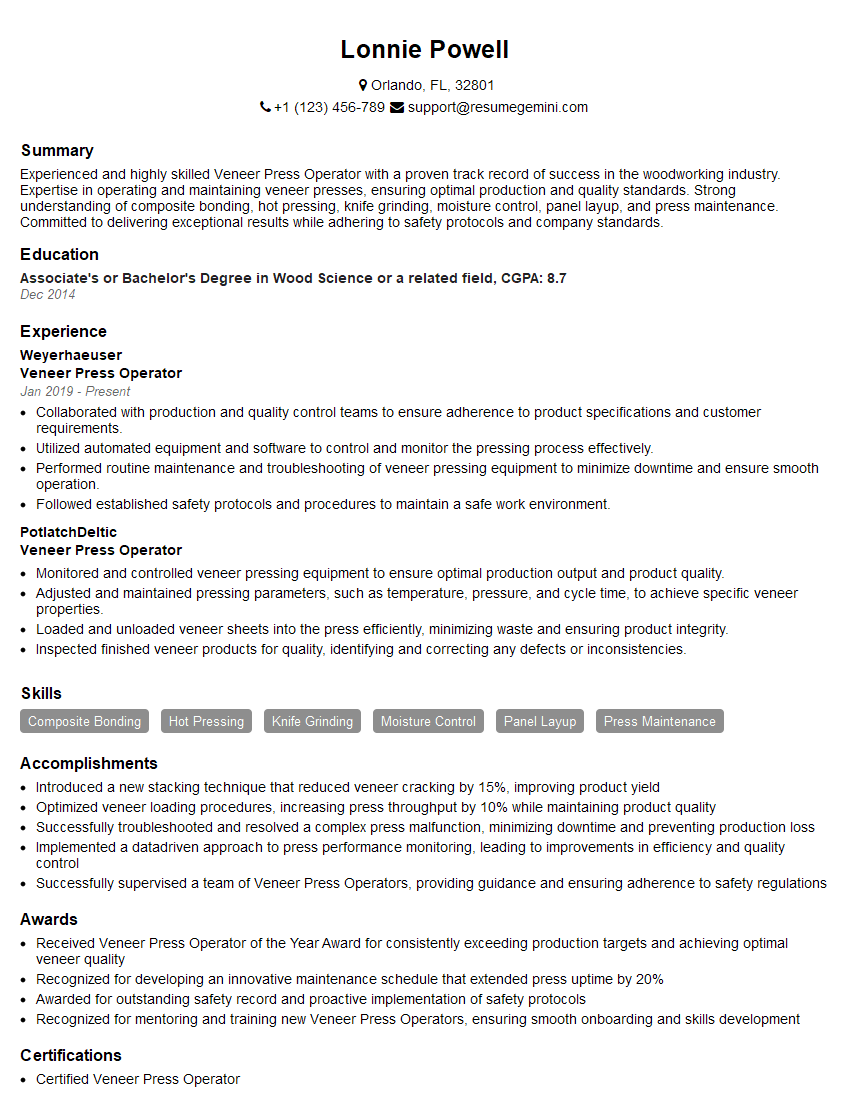

Lonnie Powell

Veneer Press Operator

Summary

Experienced and highly skilled Veneer Press Operator with a proven track record of success in the woodworking industry. Expertise in operating and maintaining veneer presses, ensuring optimal production and quality standards. Strong understanding of composite bonding, hot pressing, knife grinding, moisture control, panel layup, and press maintenance. Committed to delivering exceptional results while adhering to safety protocols and company standards.

Education

Associate’s or Bachelor’s Degree in Wood Science or a related field

December 2014

Skills

- Composite Bonding

- Hot Pressing

- Knife Grinding

- Moisture Control

- Panel Layup

- Press Maintenance

Work Experience

Veneer Press Operator

- Collaborated with production and quality control teams to ensure adherence to product specifications and customer requirements.

- Utilized automated equipment and software to control and monitor the pressing process effectively.

- Performed routine maintenance and troubleshooting of veneer pressing equipment to minimize downtime and ensure smooth operation.

- Followed established safety protocols and procedures to maintain a safe work environment.

Veneer Press Operator

- Monitored and controlled veneer pressing equipment to ensure optimal production output and product quality.

- Adjusted and maintained pressing parameters, such as temperature, pressure, and cycle time, to achieve specific veneer properties.

- Loaded and unloaded veneer sheets into the press efficiently, minimizing waste and ensuring product integrity.

- Inspected finished veneer products for quality, identifying and correcting any defects or inconsistencies.

Accomplishments

- Introduced a new stacking technique that reduced veneer cracking by 15%, improving product yield

- Optimized veneer loading procedures, increasing press throughput by 10% while maintaining product quality

- Successfully troubleshooted and resolved a complex press malfunction, minimizing downtime and preventing production loss

- Implemented a datadriven approach to press performance monitoring, leading to improvements in efficiency and quality control

- Successfully supervised a team of Veneer Press Operators, providing guidance and ensuring adherence to safety regulations

Awards

- Received Veneer Press Operator of the Year Award for consistently exceeding production targets and achieving optimal veneer quality

- Recognized for developing an innovative maintenance schedule that extended press uptime by 20%

- Awarded for outstanding safety record and proactive implementation of safety protocols

- Recognized for mentoring and training new Veneer Press Operators, ensuring smooth onboarding and skills development

Certificates

- Certified Veneer Press Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Veneer Press Operator

- Highlight your experience and expertise in operating and maintaining veneer presses.

- Quantify your accomplishments and provide specific examples of your contributions.

- Emphasize your understanding of composite bonding, hot pressing, and other relevant techniques.

- Demonstrate your commitment to safety and adherence to industry standards.

Essential Experience Highlights for a Strong Veneer Press Operator Resume

- Operate and maintain veneer presses to produce high-quality veneer products.

- Monitor press settings, temperature, and pressure to ensure optimal bonding.

- Perform knife grinding and maintenance to ensure precise cutting and smooth surface finishes.

- Control moisture content of veneers to prevent warping and ensure proper bonding.

- Lay up veneers and prepare them for pressing, ensuring proper alignment and adhesion.

- Inspect finished products to ensure they meet specifications and quality standards.

- Maintain a clean and organized work area, adhering to safety protocols and industry best practices.

Frequently Asked Questions (FAQ’s) For Veneer Press Operator

What are the essential skills required for a Veneer Press Operator?

Essential skills include operating and maintaining veneer presses, knife grinding, moisture control, panel layup, and press maintenance.

What is the work environment like for a Veneer Press Operator?

Veneer Press Operators typically work in manufacturing plants, operating presses in a fast-paced environment. They must be able to work independently and as part of a team.

What are the career prospects for a Veneer Press Operator?

Experienced Veneer Press Operators can advance to supervisory roles, quality control positions, or production management. They may also specialize in a particular area, such as knife grinding or moisture control.

What is the average salary for a Veneer Press Operator?

The average salary for a Veneer Press Operator in the United States is around $45,000 per year.

What are the educational requirements for a Veneer Press Operator?

Most Veneer Press Operators have a high school diploma or equivalent. Some employers may prefer candidates with an associate’s or bachelor’s degree in wood science or a related field.

What are the physical demands of being a Veneer Press Operator?

Veneer Press Operators must be able to stand for long periods, lift heavy objects, and work in a fast-paced environment. They must also be able to tolerate noise and dust.