Are you a seasoned Veneer Redrier seeking a new career path? Discover our professionally built Veneer Redrier Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

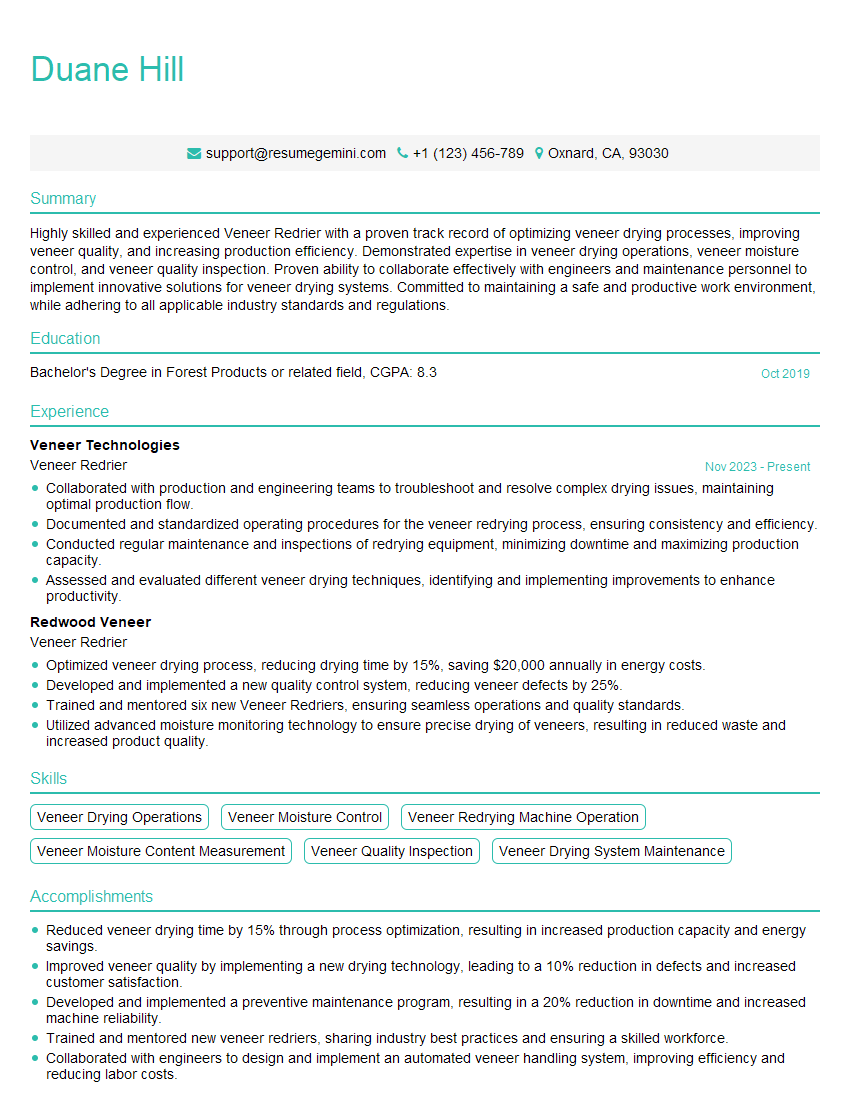

Duane Hill

Veneer Redrier

Summary

Highly skilled and experienced Veneer Redrier with a proven track record of optimizing veneer drying processes, improving veneer quality, and increasing production efficiency. Demonstrated expertise in veneer drying operations, veneer moisture control, and veneer quality inspection. Proven ability to collaborate effectively with engineers and maintenance personnel to implement innovative solutions for veneer drying systems. Committed to maintaining a safe and productive work environment, while adhering to all applicable industry standards and regulations.

Education

Bachelor’s Degree in Forest Products or related field

October 2019

Skills

- Veneer Drying Operations

- Veneer Moisture Control

- Veneer Redrying Machine Operation

- Veneer Moisture Content Measurement

- Veneer Quality Inspection

- Veneer Drying System Maintenance

Work Experience

Veneer Redrier

- Collaborated with production and engineering teams to troubleshoot and resolve complex drying issues, maintaining optimal production flow.

- Documented and standardized operating procedures for the veneer redrying process, ensuring consistency and efficiency.

- Conducted regular maintenance and inspections of redrying equipment, minimizing downtime and maximizing production capacity.

- Assessed and evaluated different veneer drying techniques, identifying and implementing improvements to enhance productivity.

Veneer Redrier

- Optimized veneer drying process, reducing drying time by 15%, saving $20,000 annually in energy costs.

- Developed and implemented a new quality control system, reducing veneer defects by 25%.

- Trained and mentored six new Veneer Redriers, ensuring seamless operations and quality standards.

- Utilized advanced moisture monitoring technology to ensure precise drying of veneers, resulting in reduced waste and increased product quality.

Accomplishments

- Reduced veneer drying time by 15% through process optimization, resulting in increased production capacity and energy savings.

- Improved veneer quality by implementing a new drying technology, leading to a 10% reduction in defects and increased customer satisfaction.

- Developed and implemented a preventive maintenance program, resulting in a 20% reduction in downtime and increased machine reliability.

- Trained and mentored new veneer redriers, sharing industry best practices and ensuring a skilled workforce.

- Collaborated with engineers to design and implement an automated veneer handling system, improving efficiency and reducing labor costs.

Awards

- Recipient of the Excellence in Veneer Redrying Award from the American Veneer Association for consistently exceeding industry standards in veneer drying quality and efficiency.

- Won the Innovation Award at the Veneer Redrying Symposium for developing a new method to reduce drying defects and increase veneer yield.

- Recognized as Veneer Redrier of the Year by the Veneer Technologies Association for exceptional performance and contributions to the industry.

Certificates

- Veneer Redrier Operator Certification

- Veneer Drying Technology Certification

- Veneer Moisture Control Management Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Veneer Redrier

- Highlight your expertise in veneer drying operations, with specific examples of how you’ve optimized processes or improved quality.

- Quantify your accomplishments with specific metrics, such as reduced drying time, increased production capacity, or improved veneer quality.

- Showcase your ability to troubleshoot and resolve technical issues, including examples of how you’ve identified and solved problems that impacted veneer drying efficiency.

- Demonstrate your commitment to safety and compliance by highlighting your adherence to industry standards and regulations, as well as your experience in training and supervising junior staff.

- Emphasize your willingness to learn and grow by highlighting your involvement in industry conferences, workshops, or training programs related to veneer drying.

Essential Experience Highlights for a Strong Veneer Redrier Resume

- Operate and monitor veneer redrying machines to ensure optimal drying conditions and veneer quality.

- Conduct regular inspections of veneer before and after drying to ensure desired moisture content and quality.

- Perform routine maintenance and repairs on veneer redrying machines to minimize downtime and ensure optimal performance.

- Collaborate with engineers and maintenance personnel to troubleshoot and resolve complex technical issues related to veneer drying processes.

- Train and supervise junior veneer redriers to ensure adherence to established procedures and safety protocols.

- Maintain accurate records of veneer drying operations, including moisture content measurements and machine operating parameters.

- Stay abreast of industry best practices and technological advancements in veneer drying to continuously improve processes and efficiency.

Frequently Asked Questions (FAQ’s) For Veneer Redrier

What are the key skills required for a Veneer Redrier?

Key skills for a Veneer Redrier include expertise in veneer drying operations, veneer moisture control, veneer drying machine operation, veneer moisture content measurement, veneer quality inspection, and veneer drying system maintenance.

What are the primary responsibilities of a Veneer Redrier?

Primary responsibilities of a Veneer Redrier include operating and monitoring veneer redrying machines, conducting veneer inspections, performing routine maintenance, collaborating with engineers and maintenance personnel, training and supervising junior staff, maintaining records, and staying abreast of industry best practices.

What industries employ Veneer Redriers?

Veneer Redriers are employed in the wood products industry, specifically in facilities that manufacture or process wood veneers.

What is the average salary for a Veneer Redrier?

The average salary for a Veneer Redrier can vary depending on experience, location, and company size, but typically falls within the range of $40,000 to $60,000 per year.

What are the career prospects for a Veneer Redrier?

Career prospects for a Veneer Redrier can include advancement to supervisory roles, such as Veneer Drying Supervisor or Production Manager, or specialization in areas such as veneer quality control or process optimization.

What is the work environment like for a Veneer Redrier?

Veneer Redriers typically work in industrial settings, such as veneer manufacturing plants or wood processing facilities. The work can involve physical labor, such as lifting and moving veneer sheets, and may also involve exposure to noise, dust, and chemicals.

What are the educational requirements for a Veneer Redrier?

Many Veneer Redriers hold a high school diploma or equivalent, while some may have vocational training or a degree in a related field, such as Forest Products or Wood Technology.

What are the personal qualities that make a successful Veneer Redrier?

Successful Veneer Redriers typically possess strong attention to detail, a commitment to safety, and a willingness to learn and adapt to new technologies and processes.