Are you a seasoned Veneer Taping Machine Offbearer seeking a new career path? Discover our professionally built Veneer Taping Machine Offbearer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

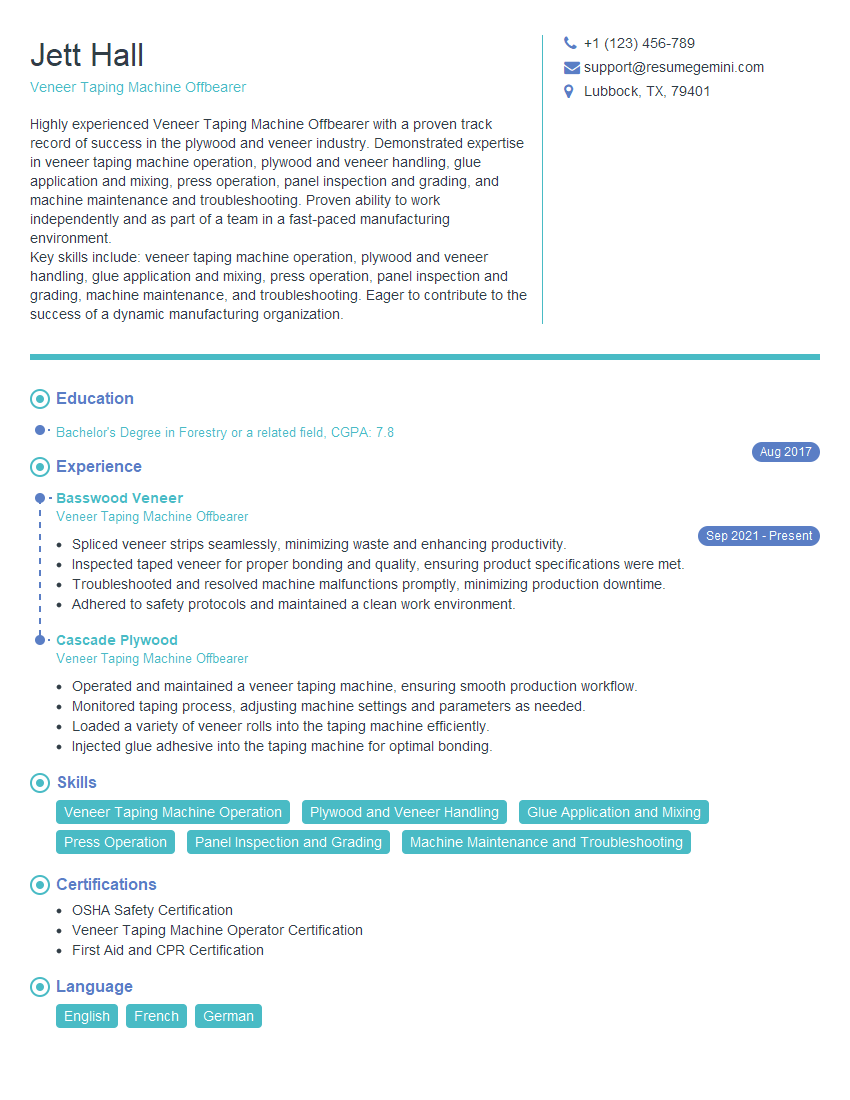

Jett Hall

Veneer Taping Machine Offbearer

Summary

Highly experienced Veneer Taping Machine Offbearer with a proven track record of success in the plywood and veneer industry. Demonstrated expertise in veneer taping machine operation, plywood and veneer handling, glue application and mixing, press operation, panel inspection and grading, and machine maintenance and troubleshooting. Proven ability to work independently and as part of a team in a fast-paced manufacturing environment.

Key skills include: veneer taping machine operation, plywood and veneer handling, glue application and mixing, press operation, panel inspection and grading, machine maintenance, and troubleshooting. Eager to contribute to the success of a dynamic manufacturing organization.

Education

Bachelor’s Degree in Forestry or a related field

August 2017

Skills

- Veneer Taping Machine Operation

- Plywood and Veneer Handling

- Glue Application and Mixing

- Press Operation

- Panel Inspection and Grading

- Machine Maintenance and Troubleshooting

Work Experience

Veneer Taping Machine Offbearer

- Spliced veneer strips seamlessly, minimizing waste and enhancing productivity.

- Inspected taped veneer for proper bonding and quality, ensuring product specifications were met.

- Troubleshooted and resolved machine malfunctions promptly, minimizing production downtime.

- Adhered to safety protocols and maintained a clean work environment.

Veneer Taping Machine Offbearer

- Operated and maintained a veneer taping machine, ensuring smooth production workflow.

- Monitored taping process, adjusting machine settings and parameters as needed.

- Loaded a variety of veneer rolls into the taping machine efficiently.

- Injected glue adhesive into the taping machine for optimal bonding.

Certificates

- OSHA Safety Certification

- Veneer Taping Machine Operator Certification

- First Aid and CPR Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Veneer Taping Machine Offbearer

- Highlight your experience and skills in veneer taping machine operation and plywood and veneer handling.

- Demonstrate your knowledge of glue application and mixing, press operation, and panel inspection and grading.

- Emphasize your ability to maintain and troubleshoot veneer taping machines.

- Showcase your attention to detail and commitment to producing high-quality products.

- Quantify your accomplishments whenever possible to demonstrate your impact on the organization.

Essential Experience Highlights for a Strong Veneer Taping Machine Offbearer Resume

- Operate and maintain veneer taping machines to produce high-quality plywood and veneer panels.

- Prepare and apply glue to veneer surfaces using manual or automatic glue applicators.

- Load and unload veneer from taping machines, ensuring proper alignment and feed.

- Monitor taping process and make adjustments as needed to ensure consistent product quality.

- Inspect finished panels for defects and grade them according to established standards.

- Troubleshoot and resolve machine malfunctions and perform routine maintenance to optimize production efficiency.

- Collaborate with other team members to ensure smooth production flow and meet customer requirements.

Frequently Asked Questions (FAQ’s) For Veneer Taping Machine Offbearer

What is the primary responsibility of a Veneer Taping Machine Offbearer?

The primary responsibility of a Veneer Taping Machine Offbearer is to operate and maintain veneer taping machines to produce high-quality plywood and veneer panels.

What skills are required to be a successful Veneer Taping Machine Offbearer?

To be successful in this role, you should have experience in veneer taping machine operation, plywood and veneer handling, glue application and mixing, press operation, panel inspection and grading, and machine maintenance and troubleshooting.

What is the work environment like for a Veneer Taping Machine Offbearer?

Veneer Taping Machine Offbearers typically work in manufacturing facilities, where they are exposed to noise and dust. They may also work in shifts and overtime to meet production demands.

What is the career outlook for a Veneer Taping Machine Offbearer?

The career outlook for Veneer Taping Machine Offbearers is expected to be stable, as there is a continuous demand for plywood and veneer products in the construction and furniture industries.

What is the average salary for a Veneer Taping Machine Offbearer?

The average salary for a Veneer Taping Machine Offbearer varies depending on experience, location, and company size, but it typically ranges from $30,000 to $50,000 per year.

What are the benefits of working as a Veneer Taping Machine Offbearer?

Benefits of working as a Veneer Taping Machine Offbearer include job security, opportunities for advancement, and a sense of accomplishment from contributing to the production of high-quality products.

What are the challenges of working as a Veneer Taping Machine Offbearer?

Challenges of working as a Veneer Taping Machine Offbearer include working in a noisy and dusty environment, working in shifts and overtime, and meeting production demands.

What is the future of the Veneer Taping Machine Offbearer profession?

The future of the Veneer Taping Machine Offbearer profession is expected to be stable, as there is a continuous demand for plywood and veneer products in the construction and furniture industries.