Are you a seasoned Wad Printing Machine Operator seeking a new career path? Discover our professionally built Wad Printing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

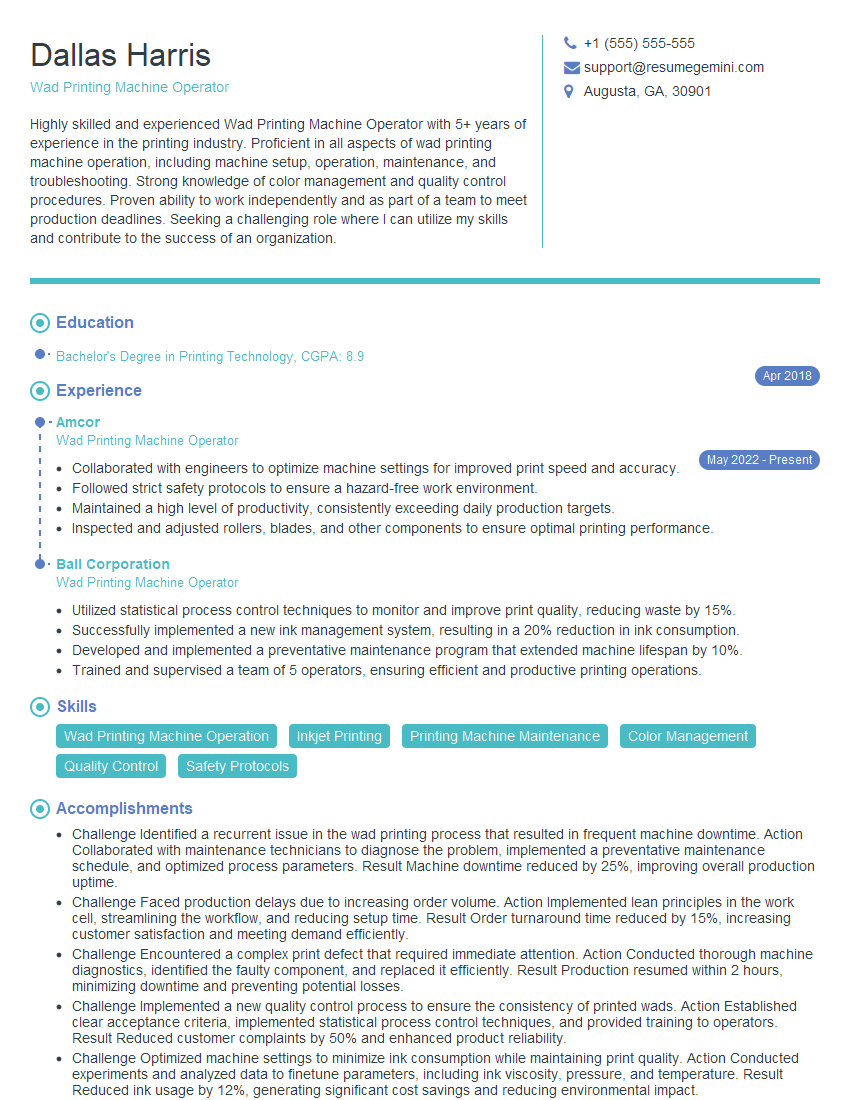

Dallas Harris

Wad Printing Machine Operator

Summary

Highly skilled and experienced Wad Printing Machine Operator with 5+ years of experience in the printing industry. Proficient in all aspects of wad printing machine operation, including machine setup, operation, maintenance, and troubleshooting. Strong knowledge of color management and quality control procedures. Proven ability to work independently and as part of a team to meet production deadlines. Seeking a challenging role where I can utilize my skills and contribute to the success of an organization.

Education

Bachelor’s Degree in Printing Technology

April 2018

Skills

- Wad Printing Machine Operation

- Inkjet Printing

- Printing Machine Maintenance

- Color Management

- Quality Control

- Safety Protocols

Work Experience

Wad Printing Machine Operator

- Collaborated with engineers to optimize machine settings for improved print speed and accuracy.

- Followed strict safety protocols to ensure a hazard-free work environment.

- Maintained a high level of productivity, consistently exceeding daily production targets.

- Inspected and adjusted rollers, blades, and other components to ensure optimal printing performance.

Wad Printing Machine Operator

- Utilized statistical process control techniques to monitor and improve print quality, reducing waste by 15%.

- Successfully implemented a new ink management system, resulting in a 20% reduction in ink consumption.

- Developed and implemented a preventative maintenance program that extended machine lifespan by 10%.

- Trained and supervised a team of 5 operators, ensuring efficient and productive printing operations.

Accomplishments

- Challenge Identified a recurrent issue in the wad printing process that resulted in frequent machine downtime. Action Collaborated with maintenance technicians to diagnose the problem, implemented a preventative maintenance schedule, and optimized process parameters. Result Machine downtime reduced by 25%, improving overall production uptime.

- Challenge Faced production delays due to increasing order volume. Action Implemented lean principles in the work cell, streamlining the workflow, and reducing setup time. Result Order turnaround time reduced by 15%, increasing customer satisfaction and meeting demand efficiently.

- Challenge Encountered a complex print defect that required immediate attention. Action Conducted thorough machine diagnostics, identified the faulty component, and replaced it efficiently. Result Production resumed within 2 hours, minimizing downtime and preventing potential losses.

- Challenge Implemented a new quality control process to ensure the consistency of printed wads. Action Established clear acceptance criteria, implemented statistical process control techniques, and provided training to operators. Result Reduced customer complaints by 50% and enhanced product reliability.

- Challenge Optimized machine settings to minimize ink consumption while maintaining print quality. Action Conducted experiments and analyzed data to finetune parameters, including ink viscosity, pressure, and temperature. Result Reduced ink usage by 12%, generating significant cost savings and reducing environmental impact.

Awards

- Recognized for achieving 99% accuracy in wad printing operations for over 12 consecutive months, leading to reduced rejects and increased production efficiency.

- Received certification in Wad Printing Quality Assurance, demonstrating proficiency in adhering to industry standards and maintaining highquality printed products.

- Nominated for the Operator of the Quarter award for consistently exceeding production targets and maintaining impeccable quality standards in wad printing operations.

- Recognized for innovative problemsolving in developing a new method to adjust print registration, reducing waste by 10% and improving product quality.

Certificates

- Certified Wad Printing Machine Operator

- Inkjet Printing Certification

- Printing Machine Maintenance Certification

- Color Management Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wad Printing Machine Operator

- Highlight your specific skills and experience in wad printing machine operation.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully for any errors before submitting it to potential employers.

Essential Experience Highlights for a Strong Wad Printing Machine Operator Resume

- Operate wad printing machines to print high-quality labels on aluminum or plastic wads.

- Set up and adjust printing machines according to job specifications, including print speed, ink flow, and tension.

- Monitor printing process and make necessary adjustments to ensure optimum print quality.

- Perform routine maintenance on printing machines, including cleaning, lubrication, and replacement of parts.

- Maintain inventory of printing supplies and order new supplies as needed.

- Ensure compliance with safety protocols and regulations.

- Work with other team members to meet production goals and deadlines.

Frequently Asked Questions (FAQ’s) For Wad Printing Machine Operator

What is a Wad Printing Machine Operator?

A Wad Printing Machine Operator is responsible for operating wad printing machines to print labels on aluminum or plastic wads. They set up and adjust printing machines, monitor the printing process, and perform routine maintenance on the machines.

What skills are required to be a Wad Printing Machine Operator?

Wad Printing Machine Operators typically need the following skills: machine operation, printing machine maintenance, color management, quality control, safety protocols, and teamwork.

What is the work environment of a Wad Printing Machine Operator like?

Wad Printing Machine Operators typically work in manufacturing facilities. They may work in a variety of conditions, including high noise levels and exposure to chemicals.

What is the salary of a Wad Printing Machine Operator?

The salary of a Wad Printing Machine Operator can vary depending on their experience, skills, and location. According to Salary.com, the average salary for a Wad Printing Machine Operator in the United States is $35,000 per year.

What are the career prospects for a Wad Printing Machine Operator?

Wad Printing Machine Operators can advance to positions such as Printing Machine Supervisor or Production Manager. They may also start their own businesses.

What are the challenges of being a Wad Printing Machine Operator?

Some of the challenges of being a Wad Printing Machine Operator include working in a noisy environment, exposure to chemicals, and the need to meet production deadlines.

What are the rewards of being a Wad Printing Machine Operator?

Some of the rewards of being a Wad Printing Machine Operator include a steady income, the opportunity to learn a valuable trade, and the satisfaction of seeing your work contribute to the production of a product.