Are you a seasoned Wafer Line Worker seeking a new career path? Discover our professionally built Wafer Line Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

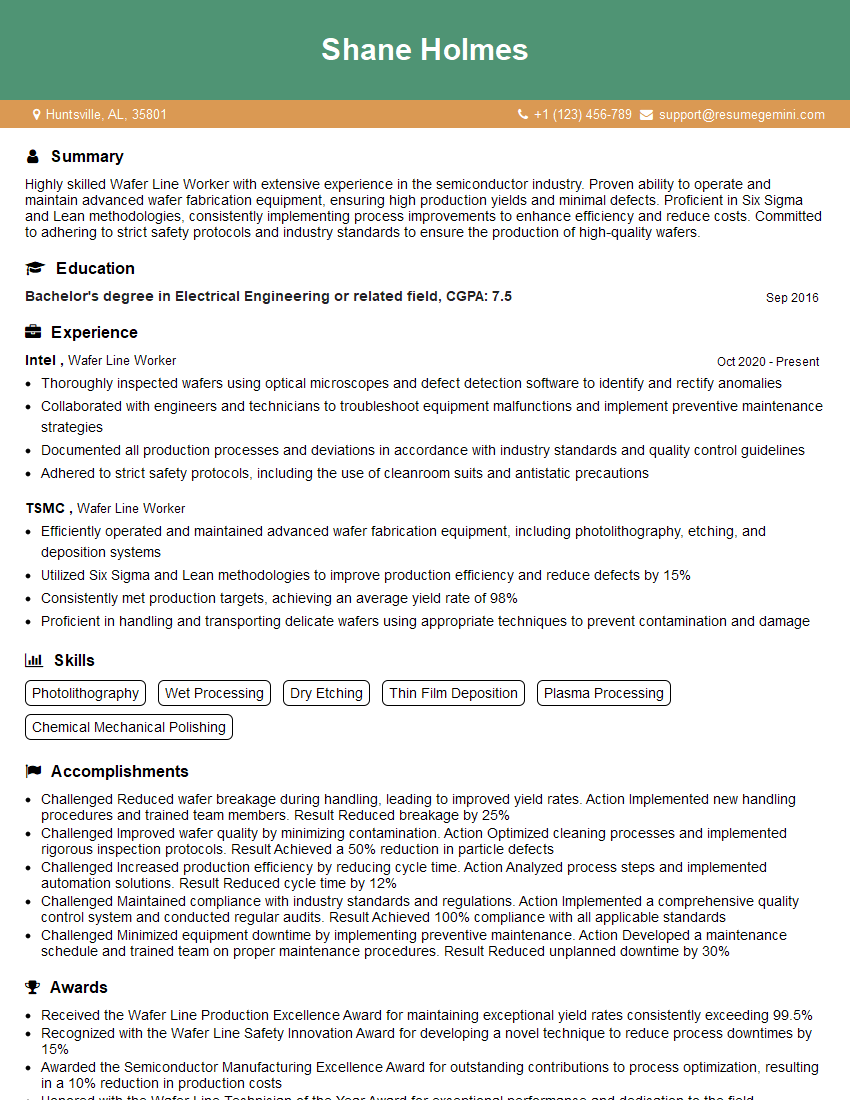

Shane Holmes

Wafer Line Worker

Summary

Highly skilled Wafer Line Worker with extensive experience in the semiconductor industry. Proven ability to operate and maintain advanced wafer fabrication equipment, ensuring high production yields and minimal defects. Proficient in Six Sigma and Lean methodologies, consistently implementing process improvements to enhance efficiency and reduce costs. Committed to adhering to strict safety protocols and industry standards to ensure the production of high-quality wafers.

Education

Bachelor’s degree in Electrical Engineering or related field

September 2016

Skills

- Photolithography

- Wet Processing

- Dry Etching

- Thin Film Deposition

- Plasma Processing

- Chemical Mechanical Polishing

Work Experience

Wafer Line Worker

- Thoroughly inspected wafers using optical microscopes and defect detection software to identify and rectify anomalies

- Collaborated with engineers and technicians to troubleshoot equipment malfunctions and implement preventive maintenance strategies

- Documented all production processes and deviations in accordance with industry standards and quality control guidelines

- Adhered to strict safety protocols, including the use of cleanroom suits and antistatic precautions

Wafer Line Worker

- Efficiently operated and maintained advanced wafer fabrication equipment, including photolithography, etching, and deposition systems

- Utilized Six Sigma and Lean methodologies to improve production efficiency and reduce defects by 15%

- Consistently met production targets, achieving an average yield rate of 98%

- Proficient in handling and transporting delicate wafers using appropriate techniques to prevent contamination and damage

Accomplishments

- Challenged Reduced wafer breakage during handling, leading to improved yield rates. Action Implemented new handling procedures and trained team members. Result Reduced breakage by 25%

- Challenged Improved wafer quality by minimizing contamination. Action Optimized cleaning processes and implemented rigorous inspection protocols. Result Achieved a 50% reduction in particle defects

- Challenged Increased production efficiency by reducing cycle time. Action Analyzed process steps and implemented automation solutions. Result Reduced cycle time by 12%

- Challenged Maintained compliance with industry standards and regulations. Action Implemented a comprehensive quality control system and conducted regular audits. Result Achieved 100% compliance with all applicable standards

- Challenged Minimized equipment downtime by implementing preventive maintenance. Action Developed a maintenance schedule and trained team on proper maintenance procedures. Result Reduced unplanned downtime by 30%

Awards

- Received the Wafer Line Production Excellence Award for maintaining exceptional yield rates consistently exceeding 99.5%

- Recognized with the Wafer Line Safety Innovation Award for developing a novel technique to reduce process downtimes by 15%

- Awarded the Semiconductor Manufacturing Excellence Award for outstanding contributions to process optimization, resulting in a 10% reduction in production costs

- Honored with the Wafer Line Technician of the Year Award for exceptional performance and dedication to the field

Certificates

- G3 Wafer Fab Certification

- SEMI Standards Certification

- OSHA Safety Certification

- ISO 9001 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wafer Line Worker

- Highlight your experience in operating and maintaining wafer fabrication equipment, including specific systems and processes.

- Quantify your accomplishments using specific metrics, such as yield rate improvement or cost reduction.

- Demonstrate your proficiency in Six Sigma and Lean methodologies, and how you have applied them to improve processes.

- Emphasize your attention to detail and commitment to quality control, showcasing your ability to identify and rectify defects.

Essential Experience Highlights for a Strong Wafer Line Worker Resume

- Operated and maintained photolithography, etching, and deposition systems with precision and accuracy.

- Utilized Six Sigma and Lean methodologies to identify and eliminate process inefficiencies, resulting in a 15% reduction in defects.

- Consistently achieved production targets, maintaining an average yield rate of 98%.

- Inspected wafers using optical microscopes and defect detection software, identifying and rectifying anomalies to prevent contamination and damage.

- Collaborated with engineers and technicians to troubleshoot equipment malfunctions and implement preventive maintenance strategies to minimize downtime.

- Documented all production processes and deviations in accordance with industry standards and quality control guidelines.

- Adhered to strict safety protocols, including the use of cleanroom suits and antistatic precautions, to maintain a safe and contamination-free work environment.

Frequently Asked Questions (FAQ’s) For Wafer Line Worker

What are the primary responsibilities of a Wafer Line Worker?

Wafer Line Workers are responsible for operating, maintaining, and troubleshooting wafer fabrication equipment, ensuring high production yields, minimal defects, and adherence to industry standards.

What skills are required to be a successful Wafer Line Worker?

Successful Wafer Line Workers possess strong technical skills in wafer fabrication processes, proficiency in Six Sigma and Lean methodologies, analytical problem-solving abilities, and a commitment to safety and quality control.

What is the work environment of a Wafer Line Worker like?

Wafer Line Workers typically work in cleanroom environments, adhering to strict safety protocols to prevent contamination and maintain a controlled manufacturing process.

What are the career advancement opportunities for Wafer Line Workers?

With experience and additional training, Wafer Line Workers can advance to roles such as Process Engineers, Equipment Technicians, or Production Supervisors.

What are the challenges faced by Wafer Line Workers?

Wafer Line Workers face challenges such as maintaining high production yields while minimizing defects, working in a fast-paced and demanding environment, and adapting to technological advancements in wafer fabrication processes.

What is the salary range for Wafer Line Workers?

The salary range for Wafer Line Workers varies depending on experience, location, and company size, but typically falls within the range of $50,000 to $100,000 per year.

What are the educational requirements for becoming a Wafer Line Worker?

While a high school diploma may suffice for entry-level positions, most Wafer Line Workers hold a Bachelor’s degree in Electrical Engineering, Chemical Engineering, or a related field.

What are some tips for writing a standout Wafer Line Worker resume?

To write a standout resume, highlight your technical skills, quantify your accomplishments, demonstrate your commitment to quality, and tailor your resume to the specific job requirements.