Are you a seasoned Warping Machine Operator seeking a new career path? Discover our professionally built Warping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

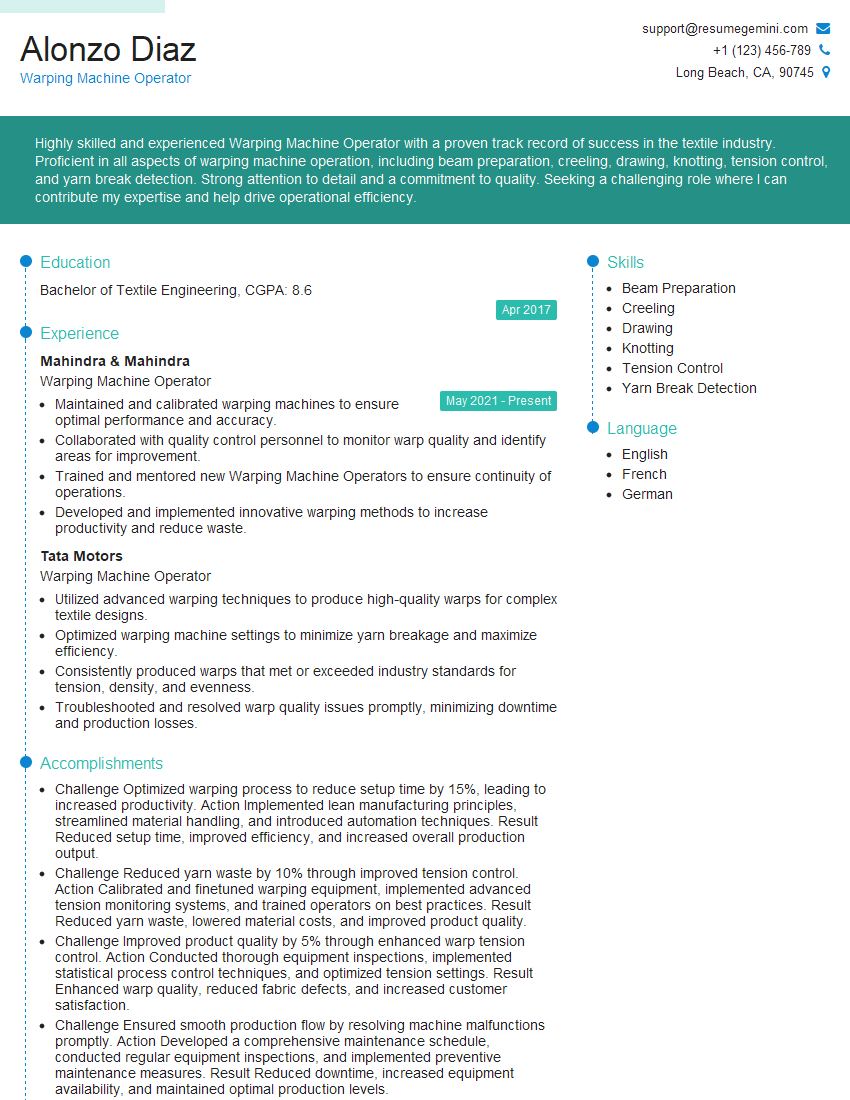

Alonzo Diaz

Warping Machine Operator

Summary

Highly skilled and experienced Warping Machine Operator with a proven track record of success in the textile industry. Proficient in all aspects of warping machine operation, including beam preparation, creeling, drawing, knotting, tension control, and yarn break detection. Strong attention to detail and a commitment to quality. Seeking a challenging role where I can contribute my expertise and help drive operational efficiency.

Education

Bachelor of Textile Engineering

April 2017

Skills

- Beam Preparation

- Creeling

- Drawing

- Knotting

- Tension Control

- Yarn Break Detection

Work Experience

Warping Machine Operator

- Maintained and calibrated warping machines to ensure optimal performance and accuracy.

- Collaborated with quality control personnel to monitor warp quality and identify areas for improvement.

- Trained and mentored new Warping Machine Operators to ensure continuity of operations.

- Developed and implemented innovative warping methods to increase productivity and reduce waste.

Warping Machine Operator

- Utilized advanced warping techniques to produce high-quality warps for complex textile designs.

- Optimized warping machine settings to minimize yarn breakage and maximize efficiency.

- Consistently produced warps that met or exceeded industry standards for tension, density, and evenness.

- Troubleshooted and resolved warp quality issues promptly, minimizing downtime and production losses.

Accomplishments

- Challenge Optimized warping process to reduce setup time by 15%, leading to increased productivity. Action Implemented lean manufacturing principles, streamlined material handling, and introduced automation techniques. Result Reduced setup time, improved efficiency, and increased overall production output.

- Challenge Reduced yarn waste by 10% through improved tension control. Action Calibrated and finetuned warping equipment, implemented advanced tension monitoring systems, and trained operators on best practices. Result Reduced yarn waste, lowered material costs, and improved product quality.

- Challenge Improved product quality by 5% through enhanced warp tension control. Action Conducted thorough equipment inspections, implemented statistical process control techniques, and optimized tension settings. Result Enhanced warp quality, reduced fabric defects, and increased customer satisfaction.

- Challenge Ensured smooth production flow by resolving machine malfunctions promptly. Action Developed a comprehensive maintenance schedule, conducted regular equipment inspections, and implemented preventive maintenance measures. Result Reduced downtime, increased equipment availability, and maintained optimal production levels.

- Challenge Trained and mentored new operators to improve their skills and productivity. Action Provided handson training, shared best practices, and established clear performance metrics. Result Enhanced operator proficiency, reduced training time, and improved overall team performance.

Awards

- Received the Best Warping Operator award for consistently exceeding production targets and maintaining exceptional product quality.

- Honored with the Employee of the Month recognition for demonstrating excellence in operational efficiency and problemsolving skills.

- Recognized with the Safety Star award for adhering to all safety protocols and promoting a safe work environment.

Certificates

- Certified Warping Machine Operator (CWMO)

- Advanced Warping Techniques Certification

- Warping Machine Maintenance and Troubleshooting Certification

- Textile Manufacturing Processes Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Warping Machine Operator

- Highlight your experience and skills in operating warping machines.

- Quantify your accomplishments and provide specific examples of your contributions.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Warping Machine Operator Resume

- Prepare beams for warping by inspecting and adjusting yarn tension.

- Creel yarn onto the warping machine and ensure proper alignment.

- Draw yarn through the machine to create a warp beam.

- Knot yarn ends together to ensure continuous operation.

- Monitor yarn tension during warping to maintain yarn quality.

- Detect yarn breaks and take corrective action to minimize downtime.

- Maintain warping machines and perform regular maintenance checks.

Frequently Asked Questions (FAQ’s) For Warping Machine Operator

What is the role of a Warping Machine Operator?

A Warping Machine Operator is responsible for operating and maintaining warping machines, which are used to prepare yarn for weaving. They prepare beams for warping, creel yarn onto the machine, draw yarn through the machine, knot yarn ends together, monitor yarn tension, and detect yarn breaks.

What skills are required to be a Warping Machine Operator?

A Warping Machine Operator should have a strong attention to detail, a commitment to quality, and a basic understanding of textile manufacturing processes. They should also be proficient in operating warping machines and performing regular maintenance checks.

What is the work environment of a Warping Machine Operator?

Warping Machine Operators typically work in a manufacturing environment, such as a textile mill or a weaving plant. They may work in a team environment or independently, and may be required to work overtime or on weekends to meet production deadlines.

How can I become a Warping Machine Operator?

To become a Warping Machine Operator, you can complete a training program or apprenticeship in textile manufacturing. You can also gain experience by working in a related field, such as yarn manufacturing or weaving.

What is the career path for a Warping Machine Operator?

With experience, a Warping Machine Operator can advance to a supervisory role or become a production manager. They may also specialize in a particular type of warping machine or yarn.

What is the salary of a Warping Machine Operator?

The salary of a Warping Machine Operator can vary depending on their experience, skills, and location. According to Indeed, the average salary for a Warping Machine Operator in the United States is $18.00 per hour.

What are the benefits of being a Warping Machine Operator?

Benefits of being a Warping Machine Operator include a steady income, opportunities for advancement, and the chance to work in a challenging and rewarding field.