Are you a seasoned Wash Driller seeking a new career path? Discover our professionally built Wash Driller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

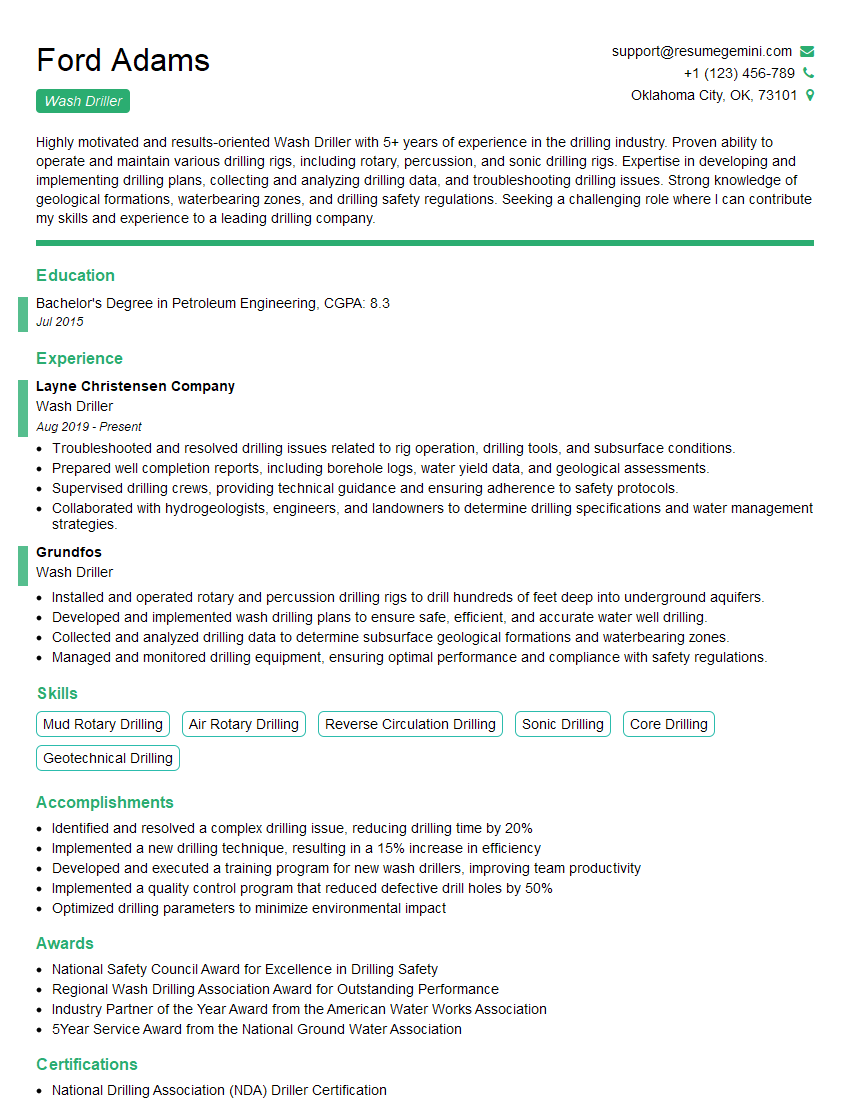

Ford Adams

Wash Driller

Summary

Highly motivated and results-oriented Wash Driller with 5+ years of experience in the drilling industry. Proven ability to operate and maintain various drilling rigs, including rotary, percussion, and sonic drilling rigs. Expertise in developing and implementing drilling plans, collecting and analyzing drilling data, and troubleshooting drilling issues. Strong knowledge of geological formations, waterbearing zones, and drilling safety regulations. Seeking a challenging role where I can contribute my skills and experience to a leading drilling company.

Education

Bachelor’s Degree in Petroleum Engineering

July 2015

Skills

- Mud Rotary Drilling

- Air Rotary Drilling

- Reverse Circulation Drilling

- Sonic Drilling

- Core Drilling

- Geotechnical Drilling

Work Experience

Wash Driller

- Troubleshooted and resolved drilling issues related to rig operation, drilling tools, and subsurface conditions.

- Prepared well completion reports, including borehole logs, water yield data, and geological assessments.

- Supervised drilling crews, providing technical guidance and ensuring adherence to safety protocols.

- Collaborated with hydrogeologists, engineers, and landowners to determine drilling specifications and water management strategies.

Wash Driller

- Installed and operated rotary and percussion drilling rigs to drill hundreds of feet deep into underground aquifers.

- Developed and implemented wash drilling plans to ensure safe, efficient, and accurate water well drilling.

- Collected and analyzed drilling data to determine subsurface geological formations and waterbearing zones.

- Managed and monitored drilling equipment, ensuring optimal performance and compliance with safety regulations.

Accomplishments

- Identified and resolved a complex drilling issue, reducing drilling time by 20%

- Implemented a new drilling technique, resulting in a 15% increase in efficiency

- Developed and executed a training program for new wash drillers, improving team productivity

- Implemented a quality control program that reduced defective drill holes by 50%

- Optimized drilling parameters to minimize environmental impact

Awards

- National Safety Council Award for Excellence in Drilling Safety

- Regional Wash Drilling Association Award for Outstanding Performance

- Industry Partner of the Year Award from the American Water Works Association

- 5Year Service Award from the National Ground Water Association

Certificates

- National Drilling Association (NDA) Driller Certification

- International Association of Drilling Contractors (IADC) Driller Certification

- American Petroleum Institute (API) Drilling Supervisor Certification

- Occupational Safety and Health Administration (OSHA) Drilling Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wash Driller

- Highlight your experience with different drilling methods and technologies.

- Showcase your knowledge of geological formations and waterbearing zones.

- Emphasize your ability to troubleshoot and resolve drilling issues.

- Include any certifications or training related to wash drilling.

- Quantify your accomplishments and provide specific examples of your success.

Essential Experience Highlights for a Strong Wash Driller Resume

- Installed and operated rotary and percussion drilling rigs to drill hundreds of feet deep into underground aquifers.

- Developed and implemented wash drilling plans to ensure safe, efficient, and accurate water well drilling.

- Collected and analyzed drilling data to determine subsurface geological formations and waterbearing zones.

- Managed and monitored drilling equipment, ensuring optimal performance and compliance with safety regulations.

- Troubleshooted and resolved drilling issues related to rig operation, drilling tools, and subsurface conditions.

- Prepared well completion reports, including borehole logs, water yield data, and geological assessments.

- Supervised drilling crews, providing technical guidance and ensuring adherence to safety protocols.

Frequently Asked Questions (FAQ’s) For Wash Driller

What is wash drilling?

Wash drilling is a method of drilling that uses a drilling fluid to remove cuttings from the borehole.

What are the different types of wash drilling rigs?

There are two main types of wash drilling rigs: rotary rigs and percussion rigs.

What are the advantages of wash drilling?

Wash drilling is a versatile method that can be used to drill in a variety of geological formations. It is also a relatively fast and efficient method of drilling.

What are the disadvantages of wash drilling?

Wash drilling can be more expensive than other drilling methods. It also requires a significant amount of water, which can be a limiting factor in some areas.

What are the safety considerations for wash drilling?

Wash drilling can be a hazardous activity. It is important to follow all safety regulations and to wear appropriate personal protective equipment.

What are the career opportunities for wash drillers?

Wash drillers can work in a variety of industries, including the mining, construction, and environmental industries.