Are you a seasoned Water Jet Operator seeking a new career path? Discover our professionally built Water Jet Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

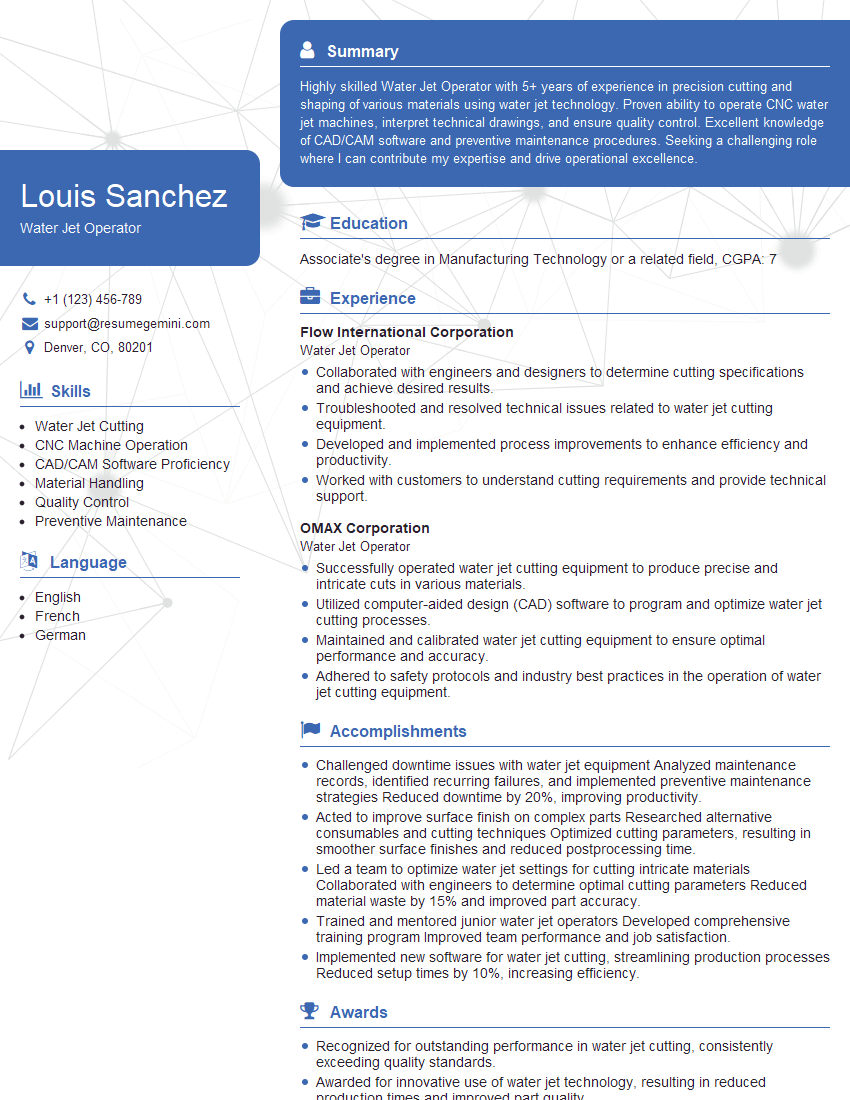

Louis Sanchez

Water Jet Operator

Summary

Highly skilled Water Jet Operator with 5+ years of experience in precision cutting and shaping of various materials using water jet technology. Proven ability to operate CNC water jet machines, interpret technical drawings, and ensure quality control. Excellent knowledge of CAD/CAM software and preventive maintenance procedures. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Associate’s degree in Manufacturing Technology or a related field

May 2015

Skills

- Water Jet Cutting

- CNC Machine Operation

- CAD/CAM Software Proficiency

- Material Handling

- Quality Control

- Preventive Maintenance

Work Experience

Water Jet Operator

- Collaborated with engineers and designers to determine cutting specifications and achieve desired results.

- Troubleshooted and resolved technical issues related to water jet cutting equipment.

- Developed and implemented process improvements to enhance efficiency and productivity.

- Worked with customers to understand cutting requirements and provide technical support.

Water Jet Operator

- Successfully operated water jet cutting equipment to produce precise and intricate cuts in various materials.

- Utilized computer-aided design (CAD) software to program and optimize water jet cutting processes.

- Maintained and calibrated water jet cutting equipment to ensure optimal performance and accuracy.

- Adhered to safety protocols and industry best practices in the operation of water jet cutting equipment.

Accomplishments

- Challenged downtime issues with water jet equipment Analyzed maintenance records, identified recurring failures, and implemented preventive maintenance strategies Reduced downtime by 20%, improving productivity.

- Acted to improve surface finish on complex parts Researched alternative consumables and cutting techniques Optimized cutting parameters, resulting in smoother surface finishes and reduced postprocessing time.

- Led a team to optimize water jet settings for cutting intricate materials Collaborated with engineers to determine optimal cutting parameters Reduced material waste by 15% and improved part accuracy.

- Trained and mentored junior water jet operators Developed comprehensive training program Improved team performance and job satisfaction.

- Implemented new software for water jet cutting, streamlining production processes Reduced setup times by 10%, increasing efficiency.

Awards

- Recognized for outstanding performance in water jet cutting, consistently exceeding quality standards.

- Awarded for innovative use of water jet technology, resulting in reduced production times and improved part quality.

- Received industry recognition for contributions to water jet operator training and development.

- Honored for exceptional safety record in water jet operations, maintaining a spotless safety record for over 5 years.

Certificates

- Water Jet Cutting Operator Certification

- CNC Operator Certification

- CAD/CAM Software Certification

- Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Water Jet Operator

- Highlight your experience with specific water jet cutting machines and software.

- Showcase your understanding of material properties and how they relate to water jet cutting.

- Quantify your accomplishments with specific metrics, such as increased productivity or reduced scrap rates.

- Demonstrate your commitment to safety and quality control.

Essential Experience Highlights for a Strong Water Jet Operator Resume

- Operate CNC water jet machines to cut and shape a wide range of materials, including metals, plastics, and composites.

- Interpret technical drawings and specifications to determine cutting parameters and setup the machine accordingly.

- Monitor the cutting process and make adjustments as needed to optimize quality and efficiency.

- Inspect finished parts to ensure they meet quality standards and customer specifications.

- Perform preventive maintenance on water jet machines, including cleaning, lubrication, and calibration.

- Troubleshoot and resolve operational issues to minimize downtime and maintain productivity.

- Collaborate with engineers and other team members to develop and implement process improvements.

Frequently Asked Questions (FAQ’s) For Water Jet Operator

What is the primary role of a Water Jet Operator?

The primary role of a Water Jet Operator is to operate CNC water jet machines to cut and shape a wide range of materials with precision and efficiency.

What are the key skills required for a Water Jet Operator?

Key skills for a Water Jet Operator include CNC machine operation, CAD/CAM software proficiency, material handling, quality control, and preventive maintenance.

What industries commonly employ Water Jet Operators?

Water Jet Operators are employed in various industries, including manufacturing, automotive, aerospace, and construction.

What are the career advancement opportunities for Water Jet Operators?

With experience and additional training, Water Jet Operators can advance to roles such as CNC Programmer, Production Supervisor, or Quality Manager.

What are the safety precautions that Water Jet Operators must follow?

Water Jet Operators must adhere to strict safety protocols, including wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work area.

How can I prepare for a career as a Water Jet Operator?

To prepare for a career as a Water Jet Operator, you can pursue an associate’s degree in Manufacturing Technology or a related field, gain hands-on experience through internships or apprenticeships, and obtain certifications in CNC machine operation and water jet cutting.

What is the average salary range for Water Jet Operators?

The average salary range for Water Jet Operators varies depending on experience, location, and industry, but typically falls between $40,000 to $70,000 per year.