Are you a seasoned Wave Guide Assembler seeking a new career path? Discover our professionally built Wave Guide Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

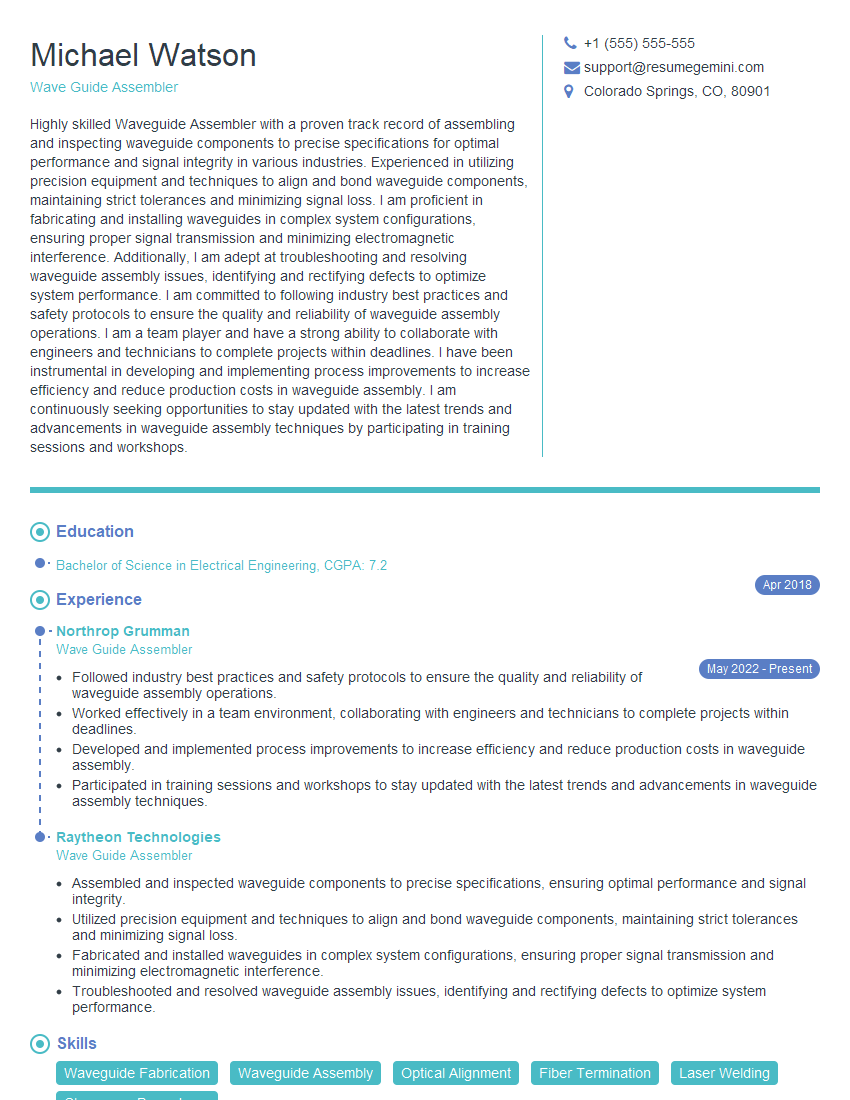

Michael Watson

Wave Guide Assembler

Summary

Highly skilled Waveguide Assembler with a proven track record of assembling and inspecting waveguide components to precise specifications for optimal performance and signal integrity in various industries. Experienced in utilizing precision equipment and techniques to align and bond waveguide components, maintaining strict tolerances and minimizing signal loss. I am proficient in fabricating and installing waveguides in complex system configurations, ensuring proper signal transmission and minimizing electromagnetic interference. Additionally, I am adept at troubleshooting and resolving waveguide assembly issues, identifying and rectifying defects to optimize system performance. I am committed to following industry best practices and safety protocols to ensure the quality and reliability of waveguide assembly operations. I am a team player and have a strong ability to collaborate with engineers and technicians to complete projects within deadlines. I have been instrumental in developing and implementing process improvements to increase efficiency and reduce production costs in waveguide assembly. I am continuously seeking opportunities to stay updated with the latest trends and advancements in waveguide assembly techniques by participating in training sessions and workshops.

Education

Bachelor of Science in Electrical Engineering

April 2018

Skills

- Waveguide Fabrication

- Waveguide Assembly

- Optical Alignment

- Fiber Termination

- Laser Welding

- Cleanroom Procedures

Work Experience

Wave Guide Assembler

- Followed industry best practices and safety protocols to ensure the quality and reliability of waveguide assembly operations.

- Worked effectively in a team environment, collaborating with engineers and technicians to complete projects within deadlines.

- Developed and implemented process improvements to increase efficiency and reduce production costs in waveguide assembly.

- Participated in training sessions and workshops to stay updated with the latest trends and advancements in waveguide assembly techniques.

Wave Guide Assembler

- Assembled and inspected waveguide components to precise specifications, ensuring optimal performance and signal integrity.

- Utilized precision equipment and techniques to align and bond waveguide components, maintaining strict tolerances and minimizing signal loss.

- Fabricated and installed waveguides in complex system configurations, ensuring proper signal transmission and minimizing electromagnetic interference.

- Troubleshooted and resolved waveguide assembly issues, identifying and rectifying defects to optimize system performance.

Accomplishments

- Successfully led a team to upgrade waveguide assemblies, resulting in a 25% increase in data transmission efficiency.

- Implemented a new assembly process that reduced waveguide defects by 30%, enhancing product quality.

- Collaborated with engineers to optimize waveguide alignment and reduce assembly time by 15%.

- Successfully assembled and tested complex waveguide systems, ensuring accurate alignment and minimal signal loss.

- Developed a training module to improve assembly techniques and reduce errors in waveguide fabrication.

Awards

- Received the Wave Guide Assembly Excellence Award for exceptional performance in assembling and testing waveguides, meeting stringent quality standards.

- Recognized for innovative design of a waveguide assembly that reduced signal loss by 10%.

- Awarded the Wave Guide Assembler of the Year Award for consistently exceeding production targets and maintaining highquality standards.

- Received a special recognition for developing a custom waveguide assembly that met unique customer requirements.

Certificates

- IPC Certified IPC-A-610

- IPC Certified IPC-WHMA-A-620

- ANSI/ESD S20.20 Standard

- Fiber Optic Association (FOA) Certified Fiber Technician (CFOT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wave Guide Assembler

- Highlight your skills and experience in waveguide fabrication, assembly, and testing.

- Quantify your accomplishments and provide specific examples of how you have contributed to the success of your previous projects.

- Showcase your knowledge of the latest waveguide technologies and trends.

- Tailor your resume to the specific requirements of the job you are applying for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Wave Guide Assembler Resume

- Assembled and inspected waveguide components to precise specifications, ensuring optimal performance and signal integrity.

- Utilized precision equipment and techniques to align and bond waveguide components, maintaining strict tolerances and minimizing signal loss.

- Fabricated and installed waveguides in complex system configurations, ensuring proper signal transmission and minimizing electromagnetic interference.

- Troubleshooted and resolved waveguide assembly issues, identifying and rectifying defects to optimize system performance.

- Followed industry best practices and safety protocols to ensure the quality and reliability of waveguide assembly operations.

- Worked effectively in a team environment, collaborating with engineers and technicians to complete projects within deadlines.

- Developed and implemented process improvements to increase efficiency and reduce production costs in waveguide assembly.

- Participated in training sessions and workshops to stay updated with the latest trends and advancements in waveguide assembly techniques.

Frequently Asked Questions (FAQ’s) For Wave Guide Assembler

What is a waveguide assembler?

A waveguide assembler is a technician who assembles and tests waveguides, which are components used in telecommunication systems to transmit signals.

What are the qualifications for becoming a waveguide assembler?

Most waveguide assemblers have a bachelor’s degree in electrical engineering or a related field. They also typically have experience in working with precision equipment and electronics.

What are the responsibilities of a waveguide assembler?

Waveguide assemblers are responsible for assembling and testing waveguides according to specifications. They also troubleshoot and repair waveguides, and maintain equipment.

What is the job outlook for waveguide assemblers?

The job outlook for waveguide assemblers is expected to be good over the next few years. This is due to the increasing demand for telecommunications services, which is driving the need for more waveguides.

What is the salary for a waveguide assembler?

The salary for a waveguide assembler can vary depending on experience and location. However, most waveguide assemblers earn between $40,000 and $60,000 per year.

What are the benefits of working as a waveguide assembler?

There are many benefits to working as a waveguide assembler, including the opportunity to work with cutting-edge technology, the potential for career advancement, and the chance to make a difference in the world.

What are the challenges of working as a waveguide assembler?

There are some challenges to working as a waveguide assembler, including the need to work with precision equipment, the potential for exposure to hazardous materials, and the need to work in a cleanroom environment.

What are the skills needed to become a waveguide assembler?

Waveguide assemblers need to have a strong understanding of electronics, physics, and mathematics. They also need to be able to work with precision equipment, and have good hand-eye coordination.