Are you a seasoned Wave Soldering Machine Operator seeking a new career path? Discover our professionally built Wave Soldering Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

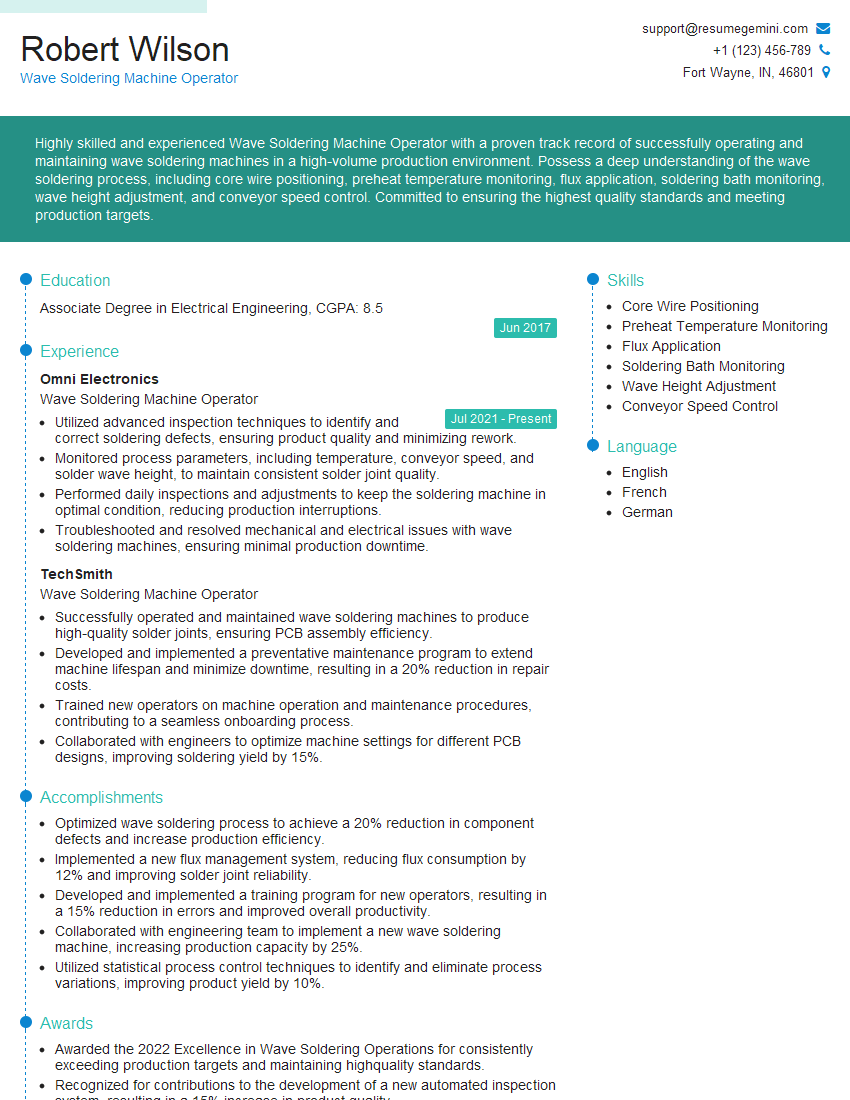

Robert Wilson

Wave Soldering Machine Operator

Summary

Highly skilled and experienced Wave Soldering Machine Operator with a proven track record of successfully operating and maintaining wave soldering machines in a high-volume production environment. Possess a deep understanding of the wave soldering process, including core wire positioning, preheat temperature monitoring, flux application, soldering bath monitoring, wave height adjustment, and conveyor speed control. Committed to ensuring the highest quality standards and meeting production targets.

Education

Associate Degree in Electrical Engineering

June 2017

Skills

- Core Wire Positioning

- Preheat Temperature Monitoring

- Flux Application

- Soldering Bath Monitoring

- Wave Height Adjustment

- Conveyor Speed Control

Work Experience

Wave Soldering Machine Operator

- Utilized advanced inspection techniques to identify and correct soldering defects, ensuring product quality and minimizing rework.

- Monitored process parameters, including temperature, conveyor speed, and solder wave height, to maintain consistent solder joint quality.

- Performed daily inspections and adjustments to keep the soldering machine in optimal condition, reducing production interruptions.

- Troubleshooted and resolved mechanical and electrical issues with wave soldering machines, ensuring minimal production downtime.

Wave Soldering Machine Operator

- Successfully operated and maintained wave soldering machines to produce high-quality solder joints, ensuring PCB assembly efficiency.

- Developed and implemented a preventative maintenance program to extend machine lifespan and minimize downtime, resulting in a 20% reduction in repair costs.

- Trained new operators on machine operation and maintenance procedures, contributing to a seamless onboarding process.

- Collaborated with engineers to optimize machine settings for different PCB designs, improving soldering yield by 15%.

Accomplishments

- Optimized wave soldering process to achieve a 20% reduction in component defects and increase production efficiency.

- Implemented a new flux management system, reducing flux consumption by 12% and improving solder joint reliability.

- Developed and implemented a training program for new operators, resulting in a 15% reduction in errors and improved overall productivity.

- Collaborated with engineering team to implement a new wave soldering machine, increasing production capacity by 25%.

- Utilized statistical process control techniques to identify and eliminate process variations, improving product yield by 10%.

Awards

- Awarded the 2022 Excellence in Wave Soldering Operations for consistently exceeding production targets and maintaining highquality standards.

- Recognized for contributions to the development of a new automated inspection system, resulting in a 15% increase in product quality.

- Received a commendation for exceptional problemsolving skills in resolving a complex issue related to solder joint integrity.

Certificates

- IPC-A-610 Certified Inspector

- IPC-J-STD-001 Certified Trainer

- ASQ Certified Quality Auditor

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wave Soldering Machine Operator

- Highlight your experience and skills in operating and maintaining wave soldering machines.

- Demonstrate your understanding of the wave soldering process and your ability to optimize machine settings for different types of PCBs.

- Showcase your attention to detail and commitment to quality by providing examples of how you have identified and corrected defects.

- Emphasize your ability to work independently and as part of a team, as well as your ability to follow safety protocols and maintain a clean and organized work environment.

- Consider including any certifications or training programs you have completed in wave soldering or related fields.

Essential Experience Highlights for a Strong Wave Soldering Machine Operator Resume

- Set up and operate wave soldering machines according to established procedures.

- Monitor and adjust preheat temperature, flux application, wave height, and conveyor speed to ensure optimal soldering results.

- Inspect printed circuit boards (PCBs) for defects before and after soldering to identify and correct any issues.

- Maintain and troubleshoot wave soldering machines to minimize downtime and ensure smooth operation.

- Follow safety protocols and wear appropriate personal protective equipment (PPE) when operating wave soldering machines.

- Collaborate with other team members to achieve production goals and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Wave Soldering Machine Operator

What are the key responsibilities of a Wave Soldering Machine Operator?

Wave Soldering Machine Operators are responsible for setting up, operating, and maintaining wave soldering machines used to solder electronic components onto printed circuit boards (PCBs). They monitor and adjust machine settings, inspect PCBs for defects, and troubleshoot and repair machines to ensure optimal performance.

What skills are required to be a successful Wave Soldering Machine Operator?

Successful Wave Soldering Machine Operators typically possess a combination of technical skills and experience, including knowledge of the wave soldering process, machine operation and maintenance, electrical safety, and quality control procedures.

What is the work environment of a Wave Soldering Machine Operator like?

Wave Soldering Machine Operators typically work in manufacturing or production facilities, operating machines in a fast-paced and often noisy environment. They may work independently or as part of a team, and must be able to follow safety protocols and maintain a clean and organized work area.

What are the career prospects for Wave Soldering Machine Operators?

Wave Soldering Machine Operators with experience and a strong track record can advance to supervisory or management roles within the manufacturing industry. They may also pursue further education or training to specialize in related fields such as electronics engineering or quality assurance.

How can I prepare for a career as a Wave Soldering Machine Operator?

To prepare for a career as a Wave Soldering Machine Operator, you can consider obtaining an associate degree or certificate in electrical engineering or a related field. You can also gain experience by working in a manufacturing or production environment, or by volunteering at organizations that offer hands-on training in electronics.

What is the average salary for a Wave Soldering Machine Operator?

The average salary for a Wave Soldering Machine Operator can vary depending on factors such as experience, location, and industry. According to Salary.com, the average annual salary for Wave Soldering Machine Operators in the United States is around $45,000.