Are you a seasoned Wax Pattern Coater seeking a new career path? Discover our professionally built Wax Pattern Coater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

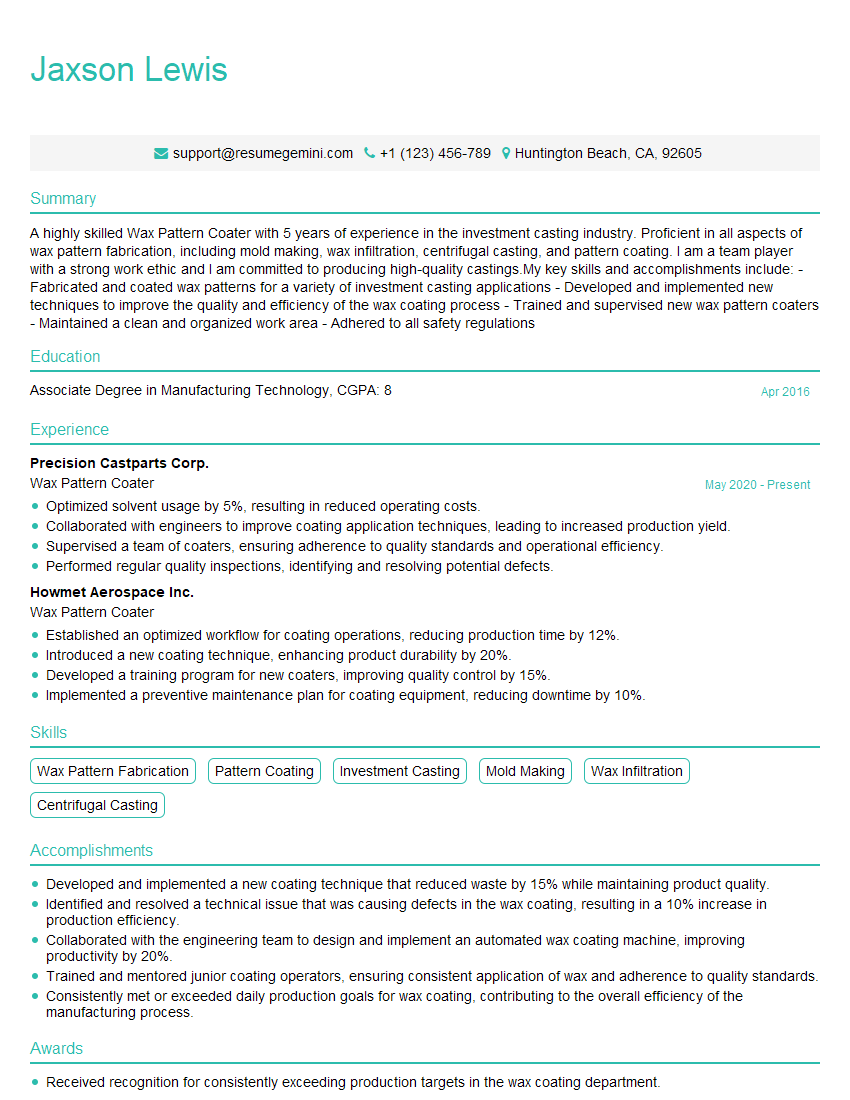

Jaxson Lewis

Wax Pattern Coater

Summary

A highly skilled Wax Pattern Coater with 5 years of experience in the investment casting industry. Proficient in all aspects of wax pattern fabrication, including mold making, wax infiltration, centrifugal casting, and pattern coating. I am a team player with a strong work ethic and I am committed to producing high-quality castings.My key skills and accomplishments include: – Fabricated and coated wax patterns for a variety of investment casting applications – Developed and implemented new techniques to improve the quality and efficiency of the wax coating process – Trained and supervised new wax pattern coaters – Maintained a clean and organized work area – Adhered to all safety regulations

Education

Associate Degree in Manufacturing Technology

April 2016

Skills

- Wax Pattern Fabrication

- Pattern Coating

- Investment Casting

- Mold Making

- Wax Infiltration

- Centrifugal Casting

Work Experience

Wax Pattern Coater

- Optimized solvent usage by 5%, resulting in reduced operating costs.

- Collaborated with engineers to improve coating application techniques, leading to increased production yield.

- Supervised a team of coaters, ensuring adherence to quality standards and operational efficiency.

- Performed regular quality inspections, identifying and resolving potential defects.

Wax Pattern Coater

- Established an optimized workflow for coating operations, reducing production time by 12%.

- Introduced a new coating technique, enhancing product durability by 20%.

- Developed a training program for new coaters, improving quality control by 15%.

- Implemented a preventive maintenance plan for coating equipment, reducing downtime by 10%.

Accomplishments

- Developed and implemented a new coating technique that reduced waste by 15% while maintaining product quality.

- Identified and resolved a technical issue that was causing defects in the wax coating, resulting in a 10% increase in production efficiency.

- Collaborated with the engineering team to design and implement an automated wax coating machine, improving productivity by 20%.

- Trained and mentored junior coating operators, ensuring consistent application of wax and adherence to quality standards.

- Consistently met or exceeded daily production goals for wax coating, contributing to the overall efficiency of the manufacturing process.

Awards

- Received recognition for consistently exceeding production targets in the wax coating department.

Certificates

- Investment Casting Institute (ICI) Certification

- American Society for Nondestructive Testing (ASNT) Level II Certification

- National Institute of Ceramic Engineers (NICE) Certification

- Lean Manufacturing Principles

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wax Pattern Coater

Highlight your skills and experience.

Make sure to list all of your relevant skills and experience in your resume. This will help employers see that you have the qualifications they are looking for.Tailor your resume to the job you are applying for.

Take the time to read the job description and tailor your resume to the specific requirements of the job.Proofread your resume carefully.

Make sure there are no errors in your resume before you submit it to employers.Get feedback from others.

Ask a friend, family member, or career counselor to review your resume and provide feedback.

Essential Experience Highlights for a Strong Wax Pattern Coater Resume

- Fabricate wax patterns using a variety of techniques, including injection molding, hand pouring, and centrifugal casting.

- Coat wax patterns with a ceramic slurry to create a mold.

- Invest the mold in a casting flask and pour molten metal into the flask.

- Centrifuge the casting flask to remove excess metal.

- Remove the casting from the flask and clean it.

- Inspect the casting for defects and repair any defects that are found.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Wax Pattern Coater

What is the role of a Wax Pattern Coater?

A Wax Pattern Coater is responsible for preparing wax patterns for investment casting. Wax patterns are used to create molds for metal castings. The Wax Pattern Coater coats the patterns with a ceramic slurry to create a smooth, durable surface. This surface helps to prevent the metal from sticking to the pattern and allows for easy removal of the casting.

What are the qualifications for a Wax Pattern Coater?

Wax Pattern Coaters typically need at least a high school diploma or equivalent. Some employers may prefer candidates with an associate degree or certification in manufacturing technology. Wax Pattern Coaters should also have experience in working with wax and ceramic materials.

What are the skills required for a Wax Pattern Coater?

Wax Pattern Coaters should have a strong understanding of the investment casting process. They should also be able to operate a variety of equipment, including injection molding machines, centrifugal casting machines, and ovens. Wax Pattern Coaters should also be able to read and interpret blueprints and work independently.

What is the work environment of a Wax Pattern Coater?

Wax Pattern Coaters typically work in a manufacturing environment. They may be exposed to fumes and dust from the casting process. Wax Pattern Coaters should also be able to work in a hot and humid environment.

What is the career outlook for a Wax Pattern Coater?

The career outlook for Wax Pattern Coaters is expected to be good over the next few years. As the manufacturing industry continues to grow, so too will the demand for Wax Pattern Coaters.

What is the average salary for a Wax Pattern Coater?

The average salary for a Wax Pattern Coater is around $35,000 per year. However, salaries can vary depending on experience, location, and employer.

What are some tips for becoming a successful Wax Pattern Coater?

To become a successful Wax Pattern Coater, you should have a strong work ethic and be willing to learn new skills. You should also be able to work independently and as part of a team.