Are you a seasoned Welder/Installer seeking a new career path? Discover our professionally built Welder/Installer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

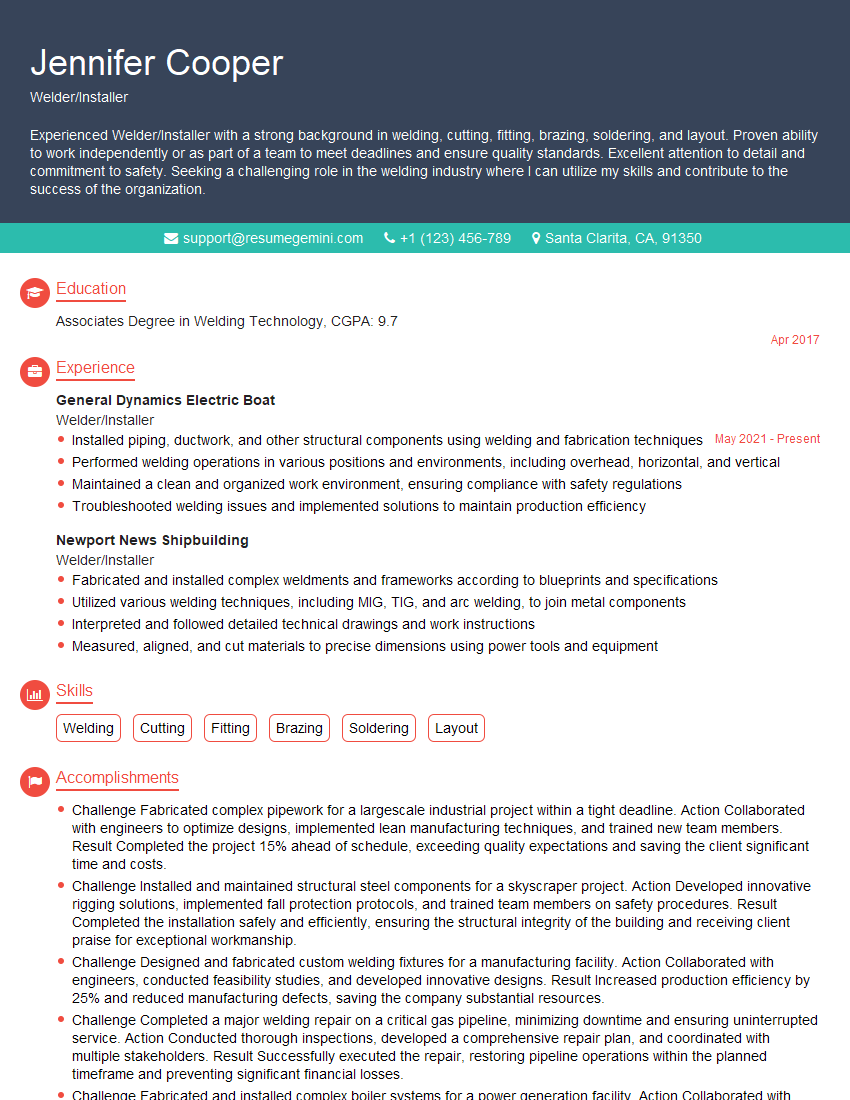

Jennifer Cooper

Welder/Installer

Summary

Experienced Welder/Installer with a strong background in welding, cutting, fitting, brazing, soldering, and layout. Proven ability to work independently or as part of a team to meet deadlines and ensure quality standards. Excellent attention to detail and commitment to safety. Seeking a challenging role in the welding industry where I can utilize my skills and contribute to the success of the organization.

Education

Associates Degree in Welding Technology

April 2017

Skills

- Welding

- Cutting

- Fitting

- Brazing

- Soldering

- Layout

Work Experience

Welder/Installer

- Installed piping, ductwork, and other structural components using welding and fabrication techniques

- Performed welding operations in various positions and environments, including overhead, horizontal, and vertical

- Maintained a clean and organized work environment, ensuring compliance with safety regulations

- Troubleshooted welding issues and implemented solutions to maintain production efficiency

Welder/Installer

- Fabricated and installed complex weldments and frameworks according to blueprints and specifications

- Utilized various welding techniques, including MIG, TIG, and arc welding, to join metal components

- Interpreted and followed detailed technical drawings and work instructions

- Measured, aligned, and cut materials to precise dimensions using power tools and equipment

Accomplishments

- Challenge Fabricated complex pipework for a largescale industrial project within a tight deadline. Action Collaborated with engineers to optimize designs, implemented lean manufacturing techniques, and trained new team members. Result Completed the project 15% ahead of schedule, exceeding quality expectations and saving the client significant time and costs.

- Challenge Installed and maintained structural steel components for a skyscraper project. Action Developed innovative rigging solutions, implemented fall protection protocols, and trained team members on safety procedures. Result Completed the installation safely and efficiently, ensuring the structural integrity of the building and receiving client praise for exceptional workmanship.

- Challenge Designed and fabricated custom welding fixtures for a manufacturing facility. Action Collaborated with engineers, conducted feasibility studies, and developed innovative designs. Result Increased production efficiency by 25% and reduced manufacturing defects, saving the company substantial resources.

- Challenge Completed a major welding repair on a critical gas pipeline, minimizing downtime and ensuring uninterrupted service. Action Conducted thorough inspections, developed a comprehensive repair plan, and coordinated with multiple stakeholders. Result Successfully executed the repair, restoring pipeline operations within the planned timeframe and preventing significant financial losses.

- Challenge Fabricated and installed complex boiler systems for a power generation facility. Action Collaborated with engineers, developed welding procedures, and supervised a team of skilled welders. Result Installed boiler systems within budget and on time, ensuring the efficient operation of the power plant.

Awards

- Recognized as Top Welder for three consecutive quarters, surpassing quality standards and exceeding production targets.

- Received the Golden Hammer Award for excellence in welding craftsmanship.

- Certified ASNT Level II Welding Inspector

- Recognized for outstanding safety performance, maintaining an impeccable safety record with zero incidents.

Certificates

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code

- National Institute for Certification in Engineering Technologies (NICET)

- American Welding Society (AWS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Welder/Installer

- Highlight your welding certifications and experience with specific welding processes.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Showcase your knowledge of welding codes and standards, such as AWS D1.1 or ASME Boiler and Pressure Vessel Code.

- Demonstrate your ability to work independently and as part of a team, with examples.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Welder/Installer Resume

- Interpret blueprints and specifications to accurately fabricate and install metal components.

- Operate various welding equipment such as MIG, TIG, and stick welders.

- Follow established welding procedures and safety regulations to ensure high-quality welds.

- Inspect completed welds to ensure they meet industry standards and specifications.

- Troubleshoot and repair welding defects promptly and effectively.

- Maintain a clean and organized work area, and ensure proper storage and handling of welding materials.

Frequently Asked Questions (FAQ’s) For Welder/Installer

What are the different types of welding processes?

There are various welding processes, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), stick welding, and flux-cored arc welding, each with its own advantages and applications.

What is the difference between a welder and an installer?

Welders primarily focus on joining and repairing metal components using various welding techniques, while installers specialize in assembling and installing prefabricated metal structures or components.

What are the most important qualities for a successful welder/installer?

Attention to detail, manual dexterity, problem-solving abilities, and a commitment to safety are crucial qualities for welders/installers.

What are the career prospects for welders/installers?

Welders/installers have a wide range of career opportunities in various industries, including construction, manufacturing, shipbuilding, and automotive, with potential for advancement to supervisory or management roles.

What is the average salary for welders/installers?

The average salary for welders and installers varies depending on experience, location, and industry, but generally falls within the range of $40,000 to $60,000 per year.

What are the common challenges faced by welders/installers?

Welders/installers may encounter challenges such as working in confined spaces, handling heavy materials, exposure to heat and fumes, and the need to stay updated with industry standards and advancements.

What is the job outlook for welders/installers?

The job outlook for welders/installers is expected to grow in the coming years, driven by increasing demand in construction, manufacturing, and infrastructure projects.