Are you a seasoned Well Service Pump Equipment Operator seeking a new career path? Discover our professionally built Well Service Pump Equipment Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

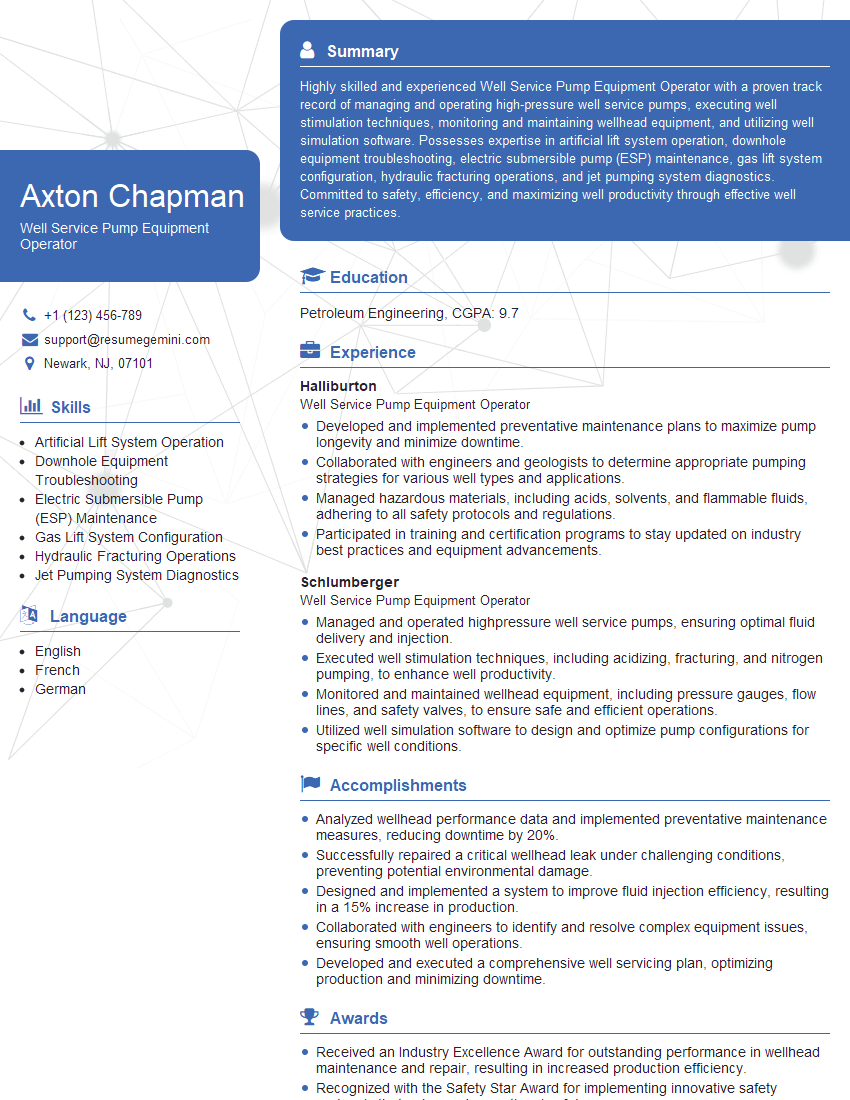

Axton Chapman

Well Service Pump Equipment Operator

Summary

Highly skilled and experienced Well Service Pump Equipment Operator with a proven track record of managing and operating high-pressure well service pumps, executing well stimulation techniques, monitoring and maintaining wellhead equipment, and utilizing well simulation software. Possesses expertise in artificial lift system operation, downhole equipment troubleshooting, electric submersible pump (ESP) maintenance, gas lift system configuration, hydraulic fracturing operations, and jet pumping system diagnostics. Committed to safety, efficiency, and maximizing well productivity through effective well service practices.

Education

Petroleum Engineering

February 2019

Skills

- Artificial Lift System Operation

- Downhole Equipment Troubleshooting

- Electric Submersible Pump (ESP) Maintenance

- Gas Lift System Configuration

- Hydraulic Fracturing Operations

- Jet Pumping System Diagnostics

Work Experience

Well Service Pump Equipment Operator

- Developed and implemented preventative maintenance plans to maximize pump longevity and minimize downtime.

- Collaborated with engineers and geologists to determine appropriate pumping strategies for various well types and applications.

- Managed hazardous materials, including acids, solvents, and flammable fluids, adhering to all safety protocols and regulations.

- Participated in training and certification programs to stay updated on industry best practices and equipment advancements.

Well Service Pump Equipment Operator

- Managed and operated highpressure well service pumps, ensuring optimal fluid delivery and injection.

- Executed well stimulation techniques, including acidizing, fracturing, and nitrogen pumping, to enhance well productivity.

- Monitored and maintained wellhead equipment, including pressure gauges, flow lines, and safety valves, to ensure safe and efficient operations.

- Utilized well simulation software to design and optimize pump configurations for specific well conditions.

Accomplishments

- Analyzed wellhead performance data and implemented preventative maintenance measures, reducing downtime by 20%.

- Successfully repaired a critical wellhead leak under challenging conditions, preventing potential environmental damage.

- Designed and implemented a system to improve fluid injection efficiency, resulting in a 15% increase in production.

- Collaborated with engineers to identify and resolve complex equipment issues, ensuring smooth well operations.

- Developed and executed a comprehensive well servicing plan, optimizing production and minimizing downtime.

Awards

- Received an Industry Excellence Award for outstanding performance in wellhead maintenance and repair, resulting in increased production efficiency.

- Recognized with the Safety Star Award for implementing innovative safety protocols that enhanced operational safety.

- Awarded the Technical Excellence Award for developing a new method to optimize pump performance, leading to increased productivity.

- Received the Leadership Award for mentoring and training junior operators, fostering a culture of excellence.

Certificates

- API 5C (Equipment for Use in Oil and Gas Production)

- API 11AX (Drilling Equipment)

- API 610 (Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries)

- API 676 (Rotary Positive Displacement Pumps)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Well Service Pump Equipment Operator

- Highlight your experience in well service pump equipment operation and maintenance.

- Quantify your results whenever possible, using metrics such as increased well productivity or reduced downtime.

- Demonstrate your knowledge of artificial lift systems, downhole equipment, and well stimulation techniques.

- Emphasize your commitment to safety and environmental compliance.

Essential Experience Highlights for a Strong Well Service Pump Equipment Operator Resume

- Managed and operated high-pressure well service pumps, ensuring optimal fluid delivery and injection.

- Executed well stimulation techniques, including acidizing, fracturing, and nitrogen pumping, to enhance well productivity.

- Monitored and maintained wellhead equipment, including pressure gauges, flow lines, and safety valves, to ensure safe and efficient operations.

- Utilized well simulation software to design and optimize pump configurations for specific well conditions.

- Developed and implemented preventative maintenance plans to maximize pump longevity and minimize downtime.

- Managed hazardous materials, including acids, solvents, and flammable fluids, adhering to all safety protocols and regulations.

Frequently Asked Questions (FAQ’s) For Well Service Pump Equipment Operator

What are the primary responsibilities of a Well Service Pump Equipment Operator?

Well Service Pump Equipment Operators are responsible for managing and operating high-pressure well service pumps, executing well stimulation techniques, monitoring and maintaining wellhead equipment, and utilizing well simulation software to optimize pump configurations and maximize well productivity.

What qualifications are required to become a Well Service Pump Equipment Operator?

Most Well Service Pump Equipment Operators hold a high school diploma or equivalent and receive on-the-job training. Some employers may prefer candidates with a degree in petroleum engineering or a related field.

What are the career prospects for Well Service Pump Equipment Operators?

Well Service Pump Equipment Operators can advance to positions such as Well Service Supervisor or Production Engineer. With experience and additional training, they may also specialize in areas such as downhole equipment troubleshooting or well stimulation.

What is the work environment like for Well Service Pump Equipment Operators?

Well Service Pump Equipment Operators typically work outdoors in oil and gas fields. They may be exposed to hazardous materials, noise, and extreme weather conditions.

What are the safety precautions that Well Service Pump Equipment Operators must follow?

Well Service Pump Equipment Operators must follow strict safety protocols and regulations to minimize risks associated with working with high-pressure equipment and hazardous materials. They must wear appropriate personal protective equipment, adhere to lockout/tagout procedures, and receive regular safety training.