Are you a seasoned Wet End Operator seeking a new career path? Discover our professionally built Wet End Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

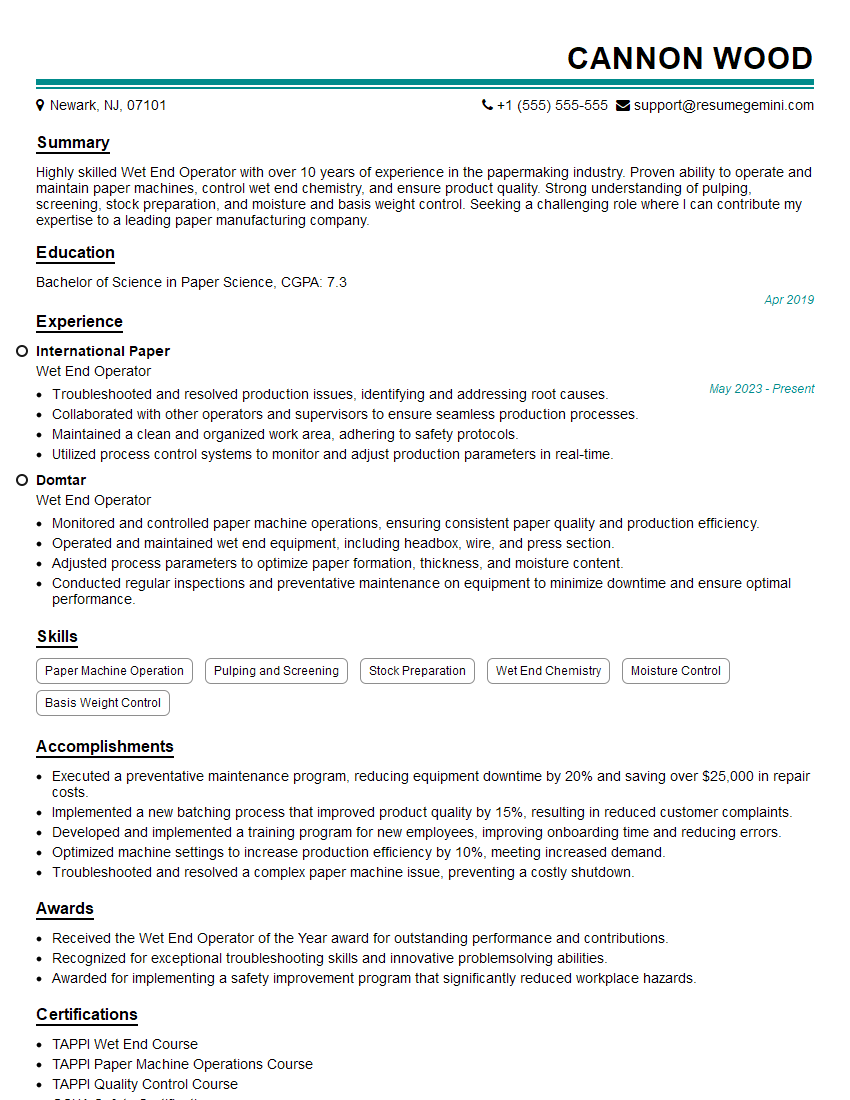

Cannon Wood

Wet End Operator

Summary

Highly skilled Wet End Operator with over 10 years of experience in the papermaking industry. Proven ability to operate and maintain paper machines, control wet end chemistry, and ensure product quality. Strong understanding of pulping, screening, stock preparation, and moisture and basis weight control. Seeking a challenging role where I can contribute my expertise to a leading paper manufacturing company.

Education

Bachelor of Science in Paper Science

April 2019

Skills

- Paper Machine Operation

- Pulping and Screening

- Stock Preparation

- Wet End Chemistry

- Moisture Control

- Basis Weight Control

Work Experience

Wet End Operator

- Troubleshooted and resolved production issues, identifying and addressing root causes.

- Collaborated with other operators and supervisors to ensure seamless production processes.

- Maintained a clean and organized work area, adhering to safety protocols.

- Utilized process control systems to monitor and adjust production parameters in real-time.

Wet End Operator

- Monitored and controlled paper machine operations, ensuring consistent paper quality and production efficiency.

- Operated and maintained wet end equipment, including headbox, wire, and press section.

- Adjusted process parameters to optimize paper formation, thickness, and moisture content.

- Conducted regular inspections and preventative maintenance on equipment to minimize downtime and ensure optimal performance.

Accomplishments

- Executed a preventative maintenance program, reducing equipment downtime by 20% and saving over $25,000 in repair costs.

- Implemented a new batching process that improved product quality by 15%, resulting in reduced customer complaints.

- Developed and implemented a training program for new employees, improving onboarding time and reducing errors.

- Optimized machine settings to increase production efficiency by 10%, meeting increased demand.

- Troubleshooted and resolved a complex paper machine issue, preventing a costly shutdown.

Awards

- Received the Wet End Operator of the Year award for outstanding performance and contributions.

- Recognized for exceptional troubleshooting skills and innovative problemsolving abilities.

- Awarded for implementing a safety improvement program that significantly reduced workplace hazards.

Certificates

- TAPPI Wet End Course

- TAPPI Paper Machine Operations Course

- TAPPI Quality Control Course

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wet End Operator

- Highlight your experience and skills in paper machine operation, wet end chemistry, and quality control.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each specific job description, emphasizing the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, ensuring that there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Wet End Operator Resume

- Operate and monitor paper machines to produce high-quality paper products

- Control wet end chemistry to optimize paper properties and minimize defects

- Monitor and adjust stock preparation processes to ensure proper fiber quality

- Conduct regular maintenance and troubleshooting of paper machines and related equipment

- Collaborate with other departments to ensure seamless production and quality control

- Supervise and train junior operators and provide technical support

- Implement process improvements to increase efficiency and reduce waste

Frequently Asked Questions (FAQ’s) For Wet End Operator

What is the role of a Wet End Operator?

A Wet End Operator is responsible for operating and maintaining paper machines, controlling wet end chemistry, and ensuring product quality in the papermaking process.

What skills are required to be a successful Wet End Operator?

Successful Wet End Operators typically have a strong understanding of paper machine operation, pulping and screening, stock preparation, wet end chemistry, moisture control, and basis weight control.

What is the career path for a Wet End Operator?

With experience and additional qualifications, Wet End Operators can advance to roles such as Production Supervisor, Quality Control Manager, or Paper Mill Manager.

What is the work environment of a Wet End Operator?

Wet End Operators typically work in a paper mill environment, which can be noisy and humid. They may work on a shift schedule, including nights and weekends.

What are the safety precautions that Wet End Operators must follow?

Wet End Operators must wear appropriate personal protective equipment (PPE), follow safety protocols, and be aware of potential hazards in the work environment.

What are the key challenges faced by Wet End Operators?

Wet End Operators may face challenges such as maintaining product quality, optimizing production efficiency, and troubleshooting equipment issues.

What are the rewards of being a Wet End Operator?

Wet End Operators can experience job satisfaction from contributing to the production of paper products and ensuring product quality. They may also enjoy working in a team environment and have the opportunity for career advancement.