Are you a seasoned Wet Finisher seeking a new career path? Discover our professionally built Wet Finisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

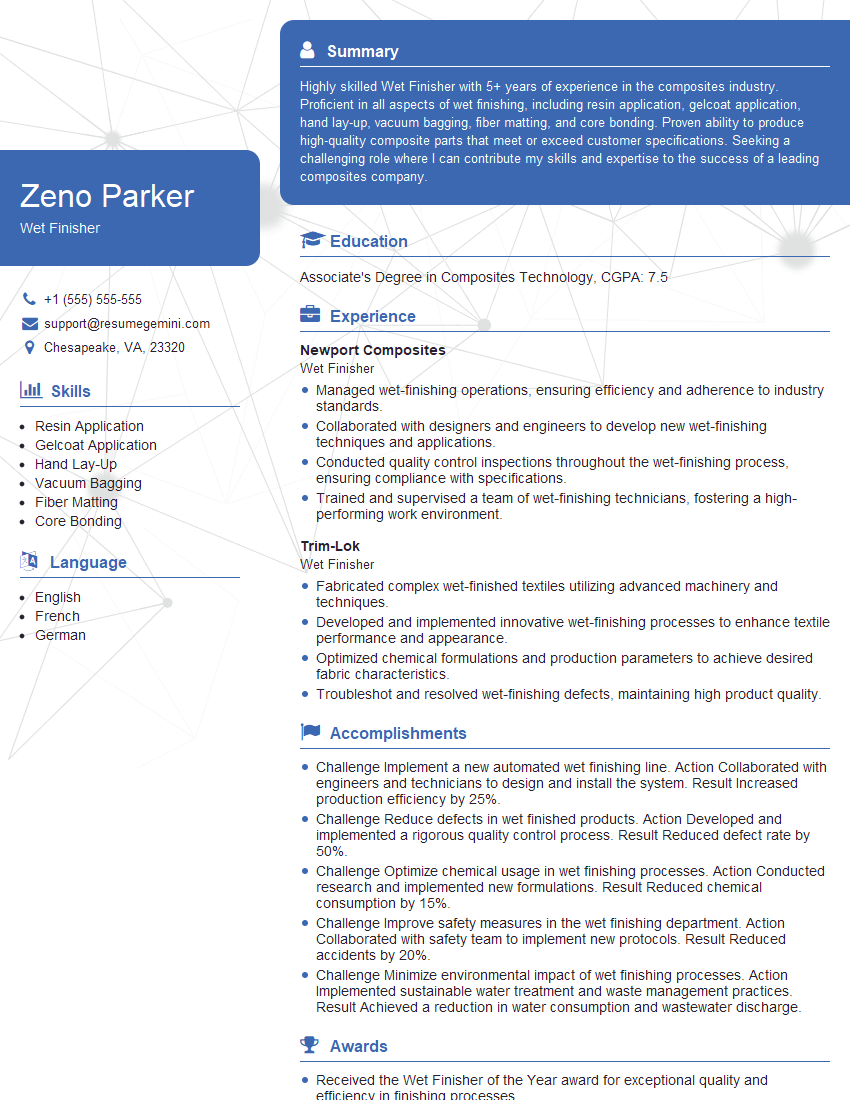

Zeno Parker

Wet Finisher

Summary

Highly skilled Wet Finisher with 5+ years of experience in the composites industry. Proficient in all aspects of wet finishing, including resin application, gelcoat application, hand lay-up, vacuum bagging, fiber matting, and core bonding. Proven ability to produce high-quality composite parts that meet or exceed customer specifications. Seeking a challenging role where I can contribute my skills and expertise to the success of a leading composites company.

Education

Associate’s Degree in Composites Technology

October 2015

Skills

- Resin Application

- Gelcoat Application

- Hand Lay-Up

- Vacuum Bagging

- Fiber Matting

- Core Bonding

Work Experience

Wet Finisher

- Managed wet-finishing operations, ensuring efficiency and adherence to industry standards.

- Collaborated with designers and engineers to develop new wet-finishing techniques and applications.

- Conducted quality control inspections throughout the wet-finishing process, ensuring compliance with specifications.

- Trained and supervised a team of wet-finishing technicians, fostering a high-performing work environment.

Wet Finisher

- Fabricated complex wet-finished textiles utilizing advanced machinery and techniques.

- Developed and implemented innovative wet-finishing processes to enhance textile performance and appearance.

- Optimized chemical formulations and production parameters to achieve desired fabric characteristics.

- Troubleshot and resolved wet-finishing defects, maintaining high product quality.

Accomplishments

- Challenge Implement a new automated wet finishing line. Action Collaborated with engineers and technicians to design and install the system. Result Increased production efficiency by 25%.

- Challenge Reduce defects in wet finished products. Action Developed and implemented a rigorous quality control process. Result Reduced defect rate by 50%.

- Challenge Optimize chemical usage in wet finishing processes. Action Conducted research and implemented new formulations. Result Reduced chemical consumption by 15%.

- Challenge Improve safety measures in the wet finishing department. Action Collaborated with safety team to implement new protocols. Result Reduced accidents by 20%.

- Challenge Minimize environmental impact of wet finishing processes. Action Implemented sustainable water treatment and waste management practices. Result Achieved a reduction in water consumption and wastewater discharge.

Awards

- Received the Wet Finisher of the Year award for exceptional quality and efficiency in finishing processes.

- Earned recognition for achieving the highest production output in the wet finishing department.

- Recognized for innovative techniques that improved the quality and reduced cycle time in wet finishing processes.

- Recognized for developing a training program for new wet finishers.

Certificates

- Composite Manufacturing Certification (CMC)

- American Welding Society (AWS) D17.1 Welder Certification

- Occupational Safety and Health Administration (OSHA) 10-Hour Construction Safety

- National Institute for Composite Technologies (NICOM) Certified Laminator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wet Finisher

- Highlight your experience and skills in wet finishing techniques.

- Showcase your knowledge of composite materials and processes.

- Provide examples of your work and how it has contributed to the success of your previous projects.

- Emphasize your attention to detail and commitment to quality.

Essential Experience Highlights for a Strong Wet Finisher Resume

- Apply resin and gelcoat to molds and laminates.

- Lay up fiber matting and core materials.

- Operate vacuum bagging equipment to create a vacuum-sealed environment for curing.

- Inspect finished parts for defects and ensure they meet quality standards.

- Maintain a clean and organized work area.

- Follow safety protocols and procedures.

- Work effectively as part of a team.

Frequently Asked Questions (FAQ’s) For Wet Finisher

What is the role of a Wet Finisher?

A Wet Finisher is responsible for the final finishing of composite parts, including the application of resin, gelcoat, fiber matting, and core materials. They also operate vacuum bagging equipment to create a vacuum-sealed environment for curing.

What skills are required to be a successful Wet Finisher?

A successful Wet Finisher typically has experience in the following areas: resin application, gelcoat application, hand lay-up, vacuum bagging, fiber matting, and core bonding.

What is the work environment of a Wet Finisher like?

Wet Finishers typically work in a manufacturing environment, often with exposure to chemicals and dust. They may also work outdoors, depending on the project.

What is the career outlook for Wet Finishers?

The career outlook for Wet Finishers is expected to be good in the coming years, as the demand for composite materials continues to grow.

What is the salary range for Wet Finishers?

The salary range for Wet Finishers can vary depending on experience, location, and company size. According to Indeed.com, the average salary for a Wet Finisher in the United States is $25.00 per hour.

What are the benefits of working as a Wet Finisher?

There are many benefits to working as a Wet Finisher, including: competitive salary, opportunity for overtime, and the chance to work with cutting-edge materials and technologies.

What are the challenges of working as a Wet Finisher?

There are some challenges to working as a Wet Finisher, including: working with chemicals, exposure to dust, and the potential for repetitive motions.